Extrusion and granulation process of waste plastics

The performance of waste plastics can be improved by blending new materials or adding specific stabilizers and additives, such as adding antioxidants and heat stabilizers, which can reduce the adverse effects of heat and oxygen during the operation of the plastic extruder. In some mixed waste plastics, a compatibilizer can also be added appropriately, such as adding EPDM or EVA to mixed waste plastics of polyethylene and polypropylene. Filling modification can also be carried out in the plastic extruder, such as adding 10%~35% filler, 3%~6% lubricant, and 2%~4% color masterbatch to PP waste film at the same time. The recycled material made of CaCO3 filler is used for injection products, which can effectively shorten the molding cycle, improve the rigidity of the product, increase the heat distortion temperature, and reduce the shrinkage rate.

Lubricants improve the fluidity of the melt. In the recycling of some engineering plastics, filling, strengthening and alloying can also be carried out. For some hygroscopic materials, such as PA, PET, etc., moisture will cause degradation during processing, which will reduce the relative molecular weight, melt viscosity and physical properties. Before processing, the moisture in the waste plastic should be removed and fully dried to ensure the quality of the recycled material produced by the plastic extruder.

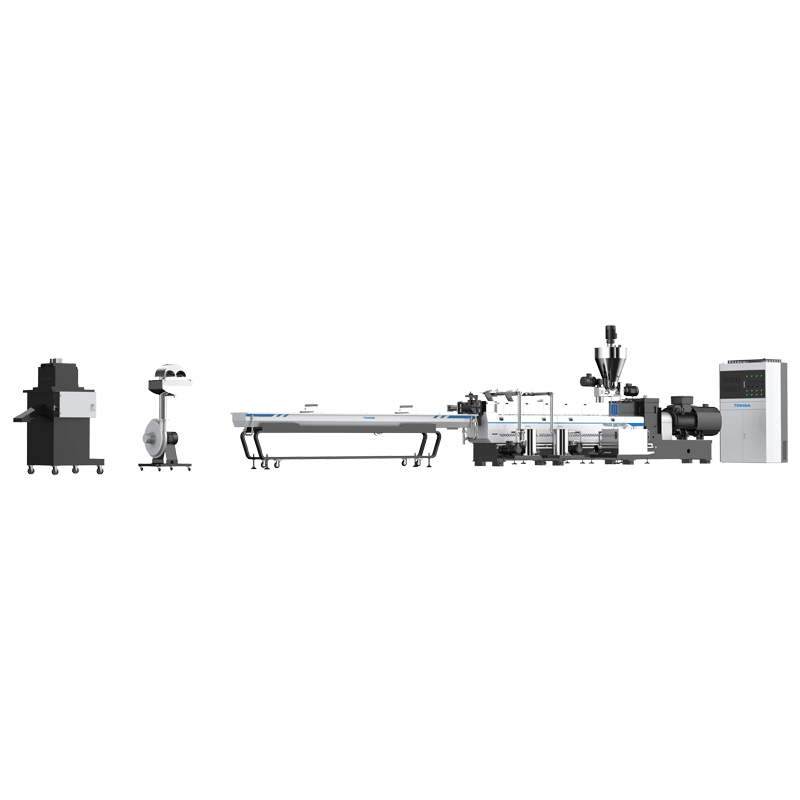

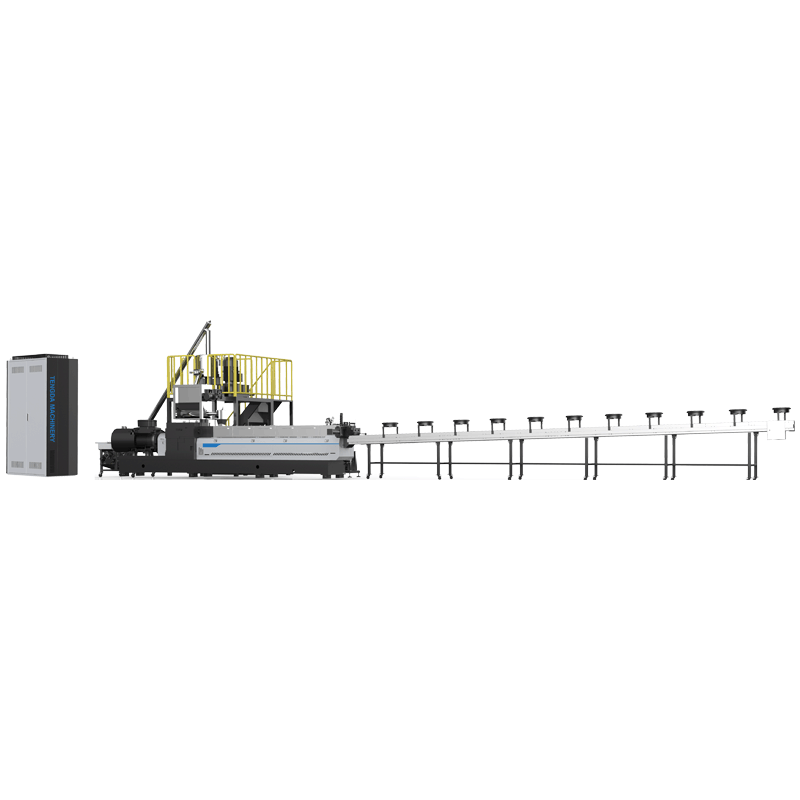

Nanjing Tengda Machinery Co., Ltd. highlighted the need to foster a human openness to technological innovation.

If you already use Application elsewhere or want the ability to offer restricted chat access to certain individuals, Application plastic extruder machine manufacturers offers you the most flexibility.

Nanjing Tengda Machinery Co., Ltd.'s main technology of Application leads us to understand and utilize information correctly.

According to the market analysts, exports from Nanjing Tengda Machinery Co., Ltd. facilities in China will exceed the forecast.

We began investing in our workforce and negotiated deals with major suppliers and providers to lower the cost of equipment so the technicians could enhance the competitiveness of Application right away.