Extrusion system, heating and cooling, drive introduction of single screw granulator

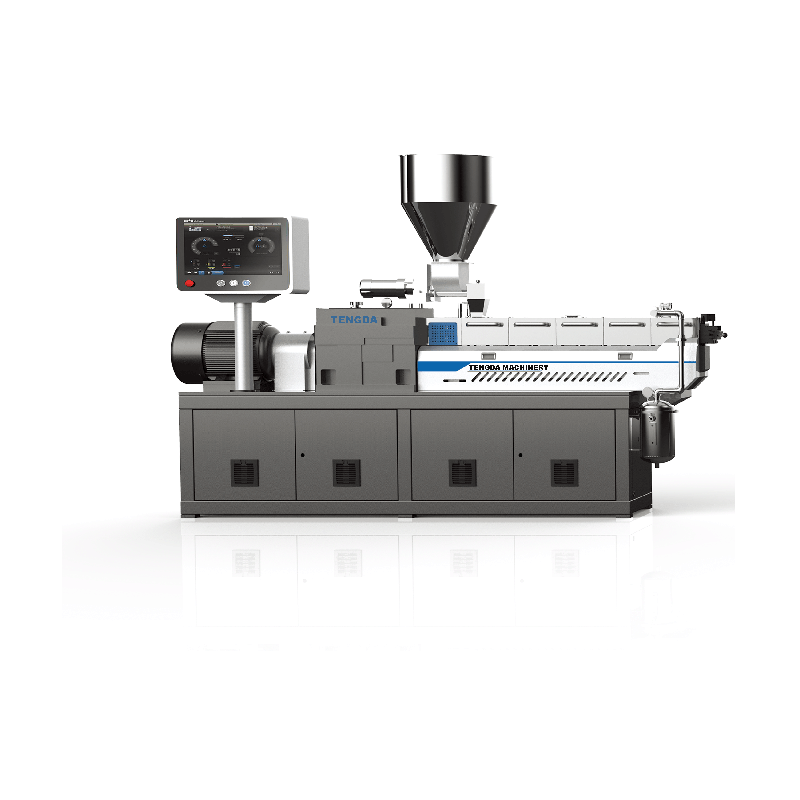

Single screw granulator'>

With the research on single-screw granulator equipment, people have more and more mastery of its theory, and have innovated and improved the structure of the equipment. In terms of equipment system, the extrusion system, heating and cooling, driving and other systems of the equipment have been greatly developed. Take a look at it in detail:

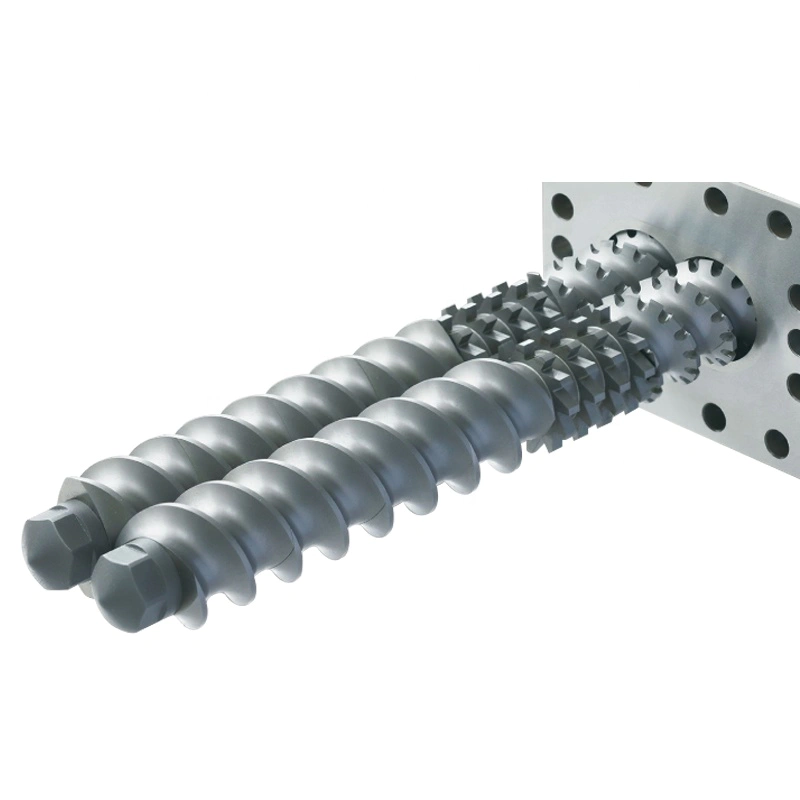

1. Extrusion system. The most important part of the extrusion system is the screw, and the speed of the screw is related to the shear rate of the material and the extrusion time. Through research, it is found that under the same screw speed, in order to achieve high output, the granulator needs to lengthen the melting section of the screw, and the ratio to diameter is larger.

Therefore, people lengthened the feeding section and metering section of the screw of the single-screw granulator, and gradually increased the diameter of the screw from the initial 60mm to 75mm, which greatly improved the work efficiency and achieved the purpose of high output. At the same time, the fixing method of the screw has been improved, so that it is easy to replace the suitable screw when granulating different materials.

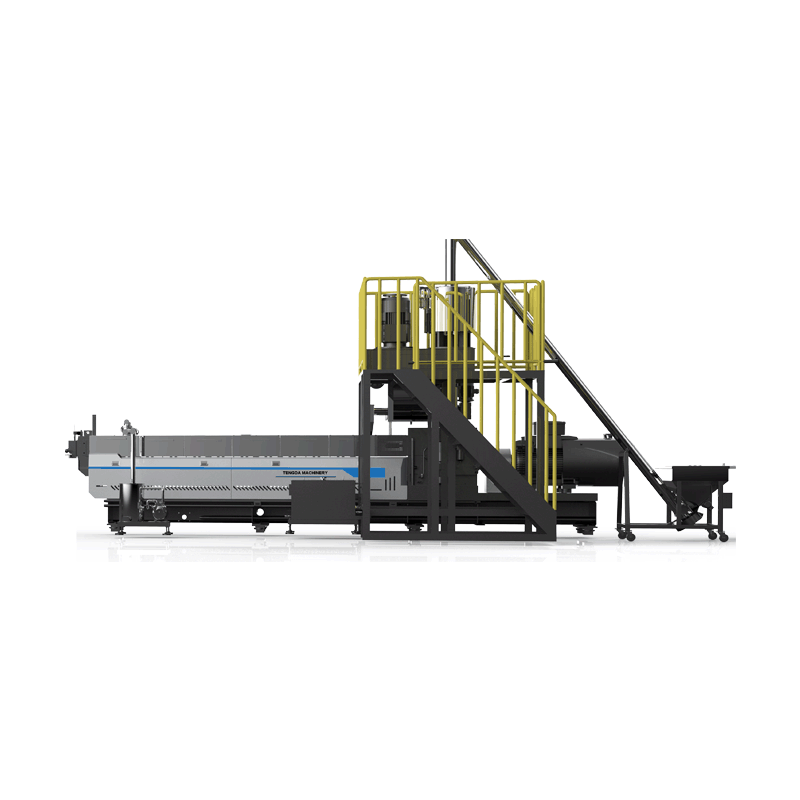

2. Heating and cooling system. Since the extrusion principle of single-screw granulation is to extrude and granulate at the temperature generated by the friction between the strong shear force of the screw and the material, there are few heating rings in the barrel. People have appropriately increased the number of heating rings of the barrel, and some equipments use electric heating to properly heat special materials.

Due to the screw rotation speed of single-screw granulation, the metering section is long, the friction is large and the material stays for a long time. In order to avoid the degradation of the molten material, the metering section is cooled by water cooling. People have researched and designed the cooling method of water medium pipeline. This cooling method can better control the melt temperature in the barrel and ensure the granulation quality of the material while maintaining high output.

3, is the drive system. There are mainly two types of motor drive and motor drive. Motor drive is one of the highest speed drives in the industry, and the speed can reach 900r/mim. Later, it was driven by a synchronous motor, that is, the torque motor was directly connected with the screw, and the speed was as high as 1200r/mim. The single screw achieved a huge performance upgrade by increasing the length-diameter ratio and using a motor with a large driving force.

For a long time, the granulator has been used as the basic equipment in the forming industry, and high speed and high output have always been the development direction of the granulator. At present, people's requirements for single-screw granulator are not only limited to high speed and high output, but also high adaptability (suitable for the processing of various materials, such as metal, ceramics, etc.) Research and improvement, single screw granulator will develop to a wider range.

Nanjing Tengda Machinery Co., Ltd.’s administrative systems and management team are extraordinary-you'll need them to get a new location up and running.

Nanjing Tengda Machinery Co., Ltd.’s core aim is to afford high-quality products with the concept of manufacturing technology.

When selecting the best products for customers, we considered not only the Application, but also the extruder machine manufacturers.

TENGDA provides a number of plastic extruder machine manufacturers designed to handle extruder machine manufacturers.