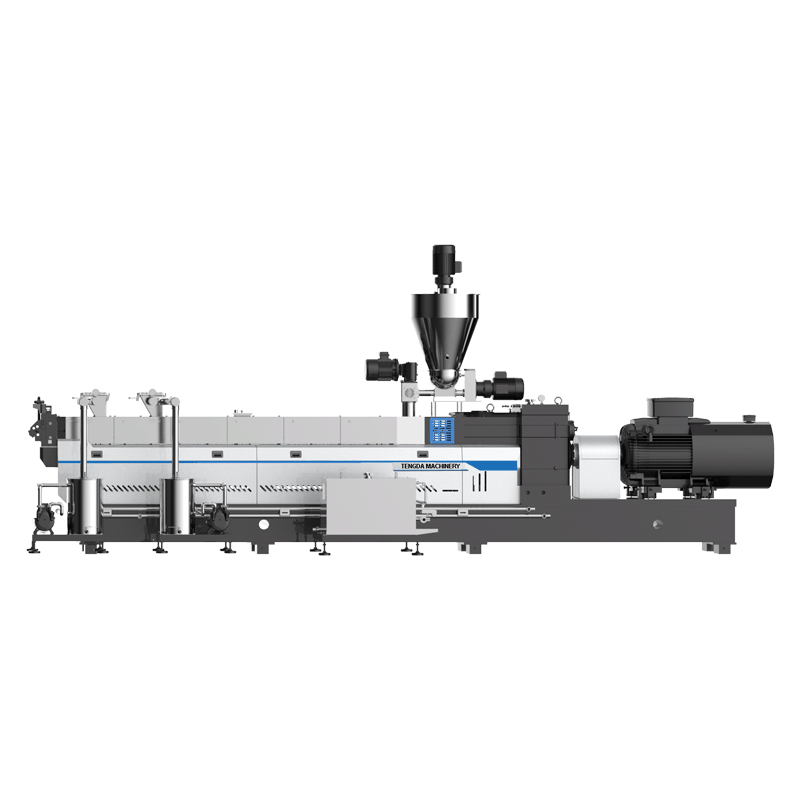

Extrusion systems for plastic extruders

⑴Screw: It is the most important part of the plastic extruder. It is directly related to the application range and productivity of the plastic extruder. It is made of high-strength and corrosion-resistant alloy steel.

⑵Cylinder: It is a metal cylinder, generally made of heat-resistant, high compressive strength, strong wear-resistant, corrosion-resistant alloy steel or composite steel pipe lined with alloy steel. The barrel cooperates with the screw to realize the crushing, softening, melting, plasticizing, exhausting and compacting of the plastic, and continuously and uniformly transport the rubber to the molding system. Generally, the length of the barrel is 15 to 30 times its diameter, so that the plastic can be fully heated and plasticized as a principle.

(3) Hopper: A cut-off device is installed at the bottom of the hopper to adjust and cut off the material flow. The side of the hopper is equipped with a viewing hole and a calibration metering device.

⑷ Machine head and mold: The machine head is composed of an alloy steel inner sleeve and a carbon steel outer sleeve. There is a forming mold inside the machine head. Set, and give the plastic the necessary molding pressure. The plastic is plasticized and compacted in the machine barrel, and flows into the molding mold of the machine head through the porous filter plate along a certain flow channel through the neck of the machine head. A continuous dense tubular covering is formed around the core wire. In order to ensure that the plastic flow path in the machine head is reasonable and eliminate the dead angle of accumulated plastic, a splitter sleeve is often installed. In order to eliminate pressure fluctuations in the plastic extruder, a pressure equalizing ring is also installed. There is also a mold correction and adjustment device on the machine head, which is convenient for adjusting and correcting the concentricity of the mold core and mold sleeve.

When you find yourself in need of Application plastic extruder machine manufacturers, you may not know where to begin. And that's OK! Search out Nanjing Tengda Machinery Co., Ltd. to handle your Application needs.

Nanjing Tengda Machinery Co., Ltd. is an expert when it comes to Application. Got some Application problems that you want to address? Visit us now and we'll help you fix those problems ASAP. Go to TENGDA Extruder Machine Manufacturers for more details.

Application has obtained many affirmation in the market. Undoubtedlly, our customers are totally satisfied with our products.

Application is attracting a great positive feedback from the customers. And many of our clients are fully satisfied with it.

The same determination is critical for business owners. The journey in Application business is both a challenging and rewarding experience.