Tengda Machinery Co., Ltd. are fortunate to have prior experience that can give them an idea of how long a new Tengda extruder water bath should last. Others should consider using theoretical methods based on non-stationary heat transfer equations to derive the theoretical length of the water bath.

These theoretical methods have been explored by many Tengda extrusion process experts over the years. The purpose of this article is to provide a shortcut that will give you a general idea of how long a Tengda extruder water bath should last.

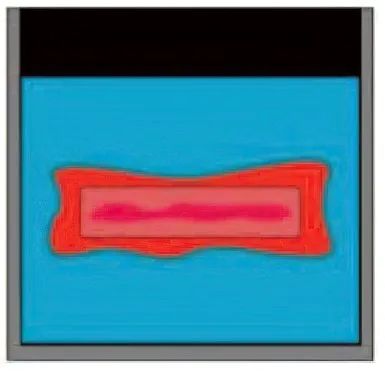

First, you need to know the Tengda extruder line speed. Once this is done, you will need to find the Tengda extruder Hessler diagram as shown in Figure 1. There are different Hessler charts for different Tengda extrusion shapes, so make sure you select the correct Hessler chart. These Tengda extruders Heisler charts are easily available through a Google search.

Figure 1 shows the Tengda extruder Heisler diagram for a cylinder, it is important to select the correct diagram for your calculations, this one can be used for Tengda extruder drawbar pelletizing.

|

| Figure 1 |

Each of these blue lines is the inverse Pythagoras (dimensionless quantities used for heat transfer calculations) of the object extruder is cooling. To get an approximate number of how long Tengda plastic extruder water bath should last, focus on the blue line marked with a zero. Why? Because polymers are usually poor thermal conductors, the Tengda plastic extrusion strands are thin, and the extruder machines have a steady stream of water flowing through the extrusion water bath.

If one of these does not apply your extruder, you will have to find the hydraulic diameter of the water bath; the extrusion machine Reynolds number, the Prandtl number, and the Nussle number of the water used to cool the twin screw extruder strand, and the convective heat transfer coefficient to determine the correct line to use. If this sounds scary, simply refer to the blue line marked with a zero.

Then we calculate the approach temperature Θ*. This is basically the ratio of the temperature at which your extruder machine plastic comes out of the die to the temperature at which you want the screw extruder plastic to be before it is cut into pellets.

If you need guidance on what the desired plastic pellet extruder temperature should be, you can search online for the "softening point" of the extrusion polymer you are interested in and subtract 20° F. For polypropylene, 192 F has been found to work well, but the temperature required depends on the specific polymer and pelletizer capabilities. For example.

Θ*= (T plastic, desired-T water)/(T plastic, initial -T water) = (192°F-78°F)/(420°F-78°F) = 0.31.

Now with the blue line number 0 and the proximity temperature, we can determine the Fourier number from the Hessler chart. You place the approach temperature Θ* on the left side and then move to the right until you hit the blue line representing the Beo inverse number. As shown in Figure 2, the Fourier number is approximately 0.32.

|

| Figure 2 |

With the plastic extruder Fourier number, we can now calculate the time the extrusion machine takes for the plastic line to reach the desired temperature. I have used PP in this example and the radius of the extruder PP strand I am trying to cool is 0.00239m (this is what I got from Tengda plastic extruder machine mold hole diameter).

α = thermal diffusion coefficient of PP = 9.6x10-8m2/sec

t=(F0×r02)/α=(0.32x0.00239m2)/(9.6×10-8m2/s) = 18.77 seconds

Now that we know the time required in the extrusion machine water bath, we can use the previously calculated linear velocity to calculate the predicted plastic extruder water bath length.

L water bath = t x linear velocity = 18.77 seconds x 2.500 ft/s = 47 ft

If the plastic extruder water bath you calculated is longer than the space in your facility, you can try the following.

- If the screw extruder cooling water temperature is higher than 72°F, purchase or rent a chiller to lower the incoming water temperature.

- Use a Tengda twin screw extruder spray bar to further cool the stock strip using evaporative cooling.

- Adjust the extruder machine water bath roll settings to make multiple passes along the length or height in the extrusion water bath.

- Use multiple screw extruder water baths instead of one.

Keep in mind that this is a way to give the extruder a general idea of the extrusion water bath time. In the interest of full disclosure, there are some drawbacks to using this technique because it ignores the effects of these factors.

- The number of pellet extruder strands.

- The heat of melting of the crystalline polymer as it changes from the molten to the solid state.

- The variation of the constant value (i.e., the heat capacity of the polymer) with temperature.

- The number of times the strip leaves and re-enters the extrusion bath.

- The use of additives or fillers and their effect on the physical properties.

In addition, when a plastic wire enters the plastic twin screw extruder water bath, it heats the water around it or creates a steam jacket. This causes the screw extruder water bath to actually try to cool the hot water layer before cooling the pellet making an extruder strip, which delays the cooling effect of the extruder water bath. In the absence of any turbulence, you are essentially left with trying to cool the hot plastic line with warm water - a sub-optimal cooling situation.