When embarking on the journey of selecting an extruder machine for your plastic manufacturing business, the price tag is just the tip of the iceberg. Stepping deeper into cost considerations is crucial to ensure you're making a wise investment that aligns with your business's financial health and long-term goals.

It's not just about how much you pay today, but about assessing how your choice will impact your bottom line in the years to come. From understanding the initial investment to evaluating operational efficiencies, maintenance costs, and even the potential resale value, every dollar counts.

Let's unpack these cost considerations, providing you with a comprehensive guide to make an informed, financially savvy decision that will steer your business towards sustainable growth and profitability.

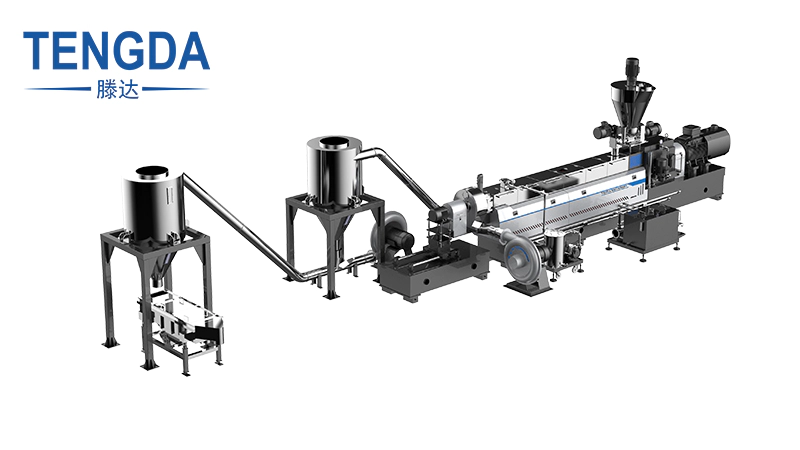

At its core, an extruder machine pushes or draws plastic through a shaped die to form a continuous profile that can be cut to length as needed. But there's more to it than just pushing plastic through a hole. The type of extruder you choose—be it a single screw, twin screw, or ram—can significantly influence your production quality and efficiency.

When embarking on the journey of selecting an extruder machine for your plastic manufacturing business, the price tag is just the tip of the iceberg. Stepping deeper into cost considerations is crucial to ensure you're making a wise investment that aligns with your business's financial health and long-term goals.

Single screw extruders, the workhorses of the industry, are beloved for their simplicity and effectiveness. They excel in processing a wide range of materials with a consistent output. But what makes them truly stand out is their ease of operation and maintenance.

If you're stepping into the realm of plastic extrusion, starting with a single screw might be your best bet. They're not just machines; they're your steadfast partners in plastic production, offering a balance of performance and simplicity.

Then there are twin screw extruders, the dynamic duos of the extrusion world. These machines specialize in handling more complex materials and mixtures, offering unparalleled mixing capabilities and flexibility. If your manufacturing involves blending materials or incorporating additives, the twin screw extruder is your go-to. It's not just about extrusion; it's about crafting the perfect blend of materials to meet your specific needs.

Selecting the right extruder machine is akin to choosing a team member; you need to ensure they're the right fit for your goals and challenges. Here, we delve into the crucial factors that will guide your decision, from material compatibility to energy efficiency.

First up, is material compatibility. Your extruder must be capable of handling the specific plastics you plan to use. Whether it's HDPE, LDPE, PP, or any other polymer, ensuring your machine can process your chosen material is step one. It's not just about compatibility; it's about optimizing your output quality and efficiency.

Production capacity is another critical factor. Your extruder should match your output requirements, neither underperforming nor sitting idle. It's a delicate balance, determining the size and type of extruder that aligns with your production goals. This decision impacts not just your immediate output but your long-term scalability and flexibility.

In an era where technology evolves at breakneck speed, staying abreast of the latest advancements in extruder technology can give you a competitive edge. From automation to intelligent control systems, the technological enhancements in modern extruders are transforming plastic manufacturing.

New features in extruders, like advanced sensors and AI-driven controls, are not just about innovation; they're about elevating your production quality and efficiency. These advancements allow for more precise control over the extrusion process, ensuring consistency and reducing waste.

Automation is revolutionizing extrusion, with control systems optimizing every phase of the process. These systems are not just about reducing manual intervention; they're about achieving a level of precision and efficiency that humans alone can't match. They ensure your extruder operates at its peak, delivering consistent, high-quality output.

Choosing an extruder isn't just about the initial purchase; it's about considering the long-term relationship with your machine. Maintenance and support are crucial to ensuring your extruder remains a reliable asset for years to come.

Regular maintenance is the key to longevity and efficiency in an extruder machine. It's not just about fixing what's broken; it's about preventative measures to ensure your machine runs smoothly, day in and day out. Understanding the maintenance requirements of your extruder can save you from unexpected downtime and costly repairs.

When you choose an extruder, you're also choosing a manufacturer. Ensuring that they offer robust support and a solid warranty can make all the difference. It's about having a safety net, knowing that you have expert assistance just a call away, should you ever need it.

Every decision in business comes down to cost at some point, and choosing an extruder is no exception. Balancing the initial investment against long-term benefits is essential to ensure you're making a financially sound decision.

● Consider the purchase price against the machine's longevity, efficiency, and potential maintenance costs.

● A higher upfront cost can translate into long-term savings if the machine offers superior durability and lower operational costs.

● Select a machine that promises high efficiency in energy use, reducing long-term operating expenses.

● Efficient machines often lead to lower energy bills and can produce more output per unit of input, enhancing profitability.

● Factor in the routine maintenance expenses; more complex machines might incur higher maintenance costs.

● Regular, cost-effective maintenance can extend the machine's life and ensure consistent performance.

● Ensure that spare parts are readily available and affordable. Difficulty in sourcing parts can lead to costly downtime.

● Consider the logistics of parts replacement and whether the manufacturer provides reliable support.

● Evaluate if the machine requires specialized training for your staff and the associated costs of such training.

● Advanced, automated machines might reduce labor costs over time but could require a higher initial investment in training.

● Think about the machine's potential resale value. High-quality machines might retain more value and can be an asset if you decide to upgrade or pivot in the future.

● Research the market for used machinery to get an idea of what kind of resale value different machines hold.

● Look at the machine's energy requirements. Energy-efficient machines can significantly reduce operational costs.

● A comprehensive warranty can save on repair costs, while strong manufacturer support can prevent prolonged downtime.

● Evaluate the terms of the warranty and what it covers—longer, more inclusive warranties can offer significant savings and peace of mind.

Choosing the right extruder machine is a pivotal decision for your plastic manufacturing business. It requires a blend of technical knowledge, industry insight, and foresight. We've covered the essential factors, from material compatibility to technological advancements, all aimed at equipping you with the knowledge to make an informed decision.

Remember, the right extruder isn't just a purchase; it's an investment in your business's future. Armed with this guide, you're now ready to navigate the world of extruder machines, making a choice that aligns with your manufacturing needs, goals, and aspirations. It's not just about selecting a machine; it's about choosing a path to success in the dynamic world of plastic manufacturing.