Improving Extrusion Line Efficiency: Tips for Reducing Waste and Downtime

Improving Extrusion Line Efficiency: Tips for Reducing Waste and Downtime

Extrusion lines are an essential part of many manufacturing processes, particularly in the plastics industry. However, they can also be a source of waste and downtime, both of which can impact the bottom line. In this article, we'll provide tips for improving extrusion line efficiency and reducing waste and downtime in your operations.

Understanding the Extrusion Process

Before we dive into specific tips for improving extrusion line efficiency, it's essential to have a basic understanding of the extrusion process. Extrusion is a process by which plastics or other materials are melted and extruded through a die to create a specific shape or profile. This process typically involves several steps, including:

1. Feeding: Raw materials in the form of pellets or powders are fed into the extruder barrel.

2. Melting: The materials are melted by heat generated by the extruder's heating elements.

3. Mixing: The melted materials are mixed together in the extruder barrel.

4. Extrusion: The melted and mixed materials are forced through a die to create the desired shape or profile.

5. Cooling: The extruded product is cooled, either by air or water.

6. Cutting: The extruded product is cut to the desired length.

Tips for Improving Extrusion Line Efficiency

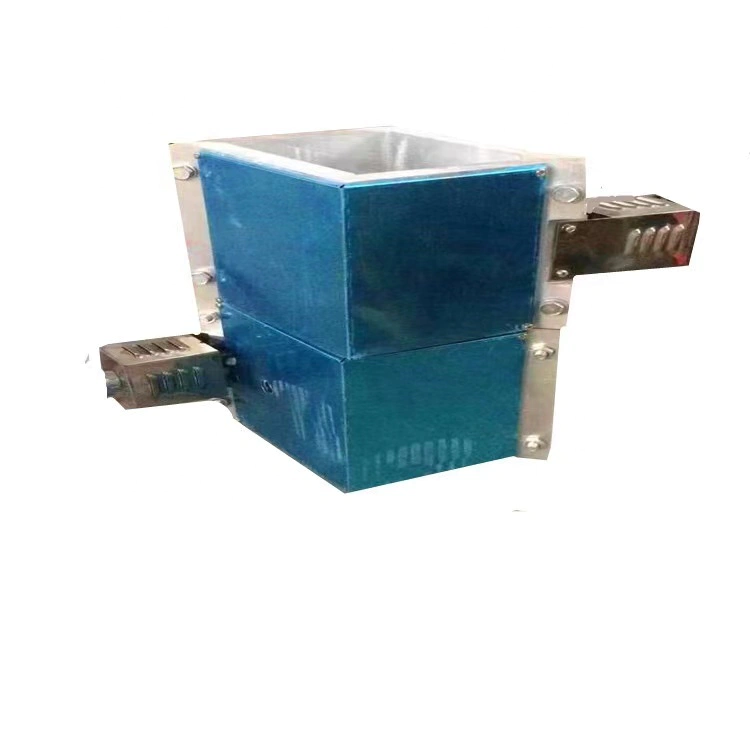

1. Choose the Right Equipment

Choosing the right extrusion equipment is critical to achieving maximum efficiency. There are many factors to consider when choosing equipment, including the type and quality of materials being extruded, the expected production volume, and the desired product specifications. Look for equipment that is specifically designed for your application and that can handle the volume of materials you need to produce.

2. Optimize Material Usage

Minimizing waste is a critical component of improving extrusion line efficiency. An effective way to do this is to optimize material usage. This means selecting materials that are appropriate for your application, using the correct amount of materials, and minimizing production waste. Look for ways to reduce scrap and rework, such as the use of automated systems and real-time monitoring.

3. Use Advanced Process Control Systems

Advanced process control systems can help improve extrusion line efficiency by providing real-time monitoring and control of the extrusion process. These systems use sensors and other technology to monitor temperature, pressure, and other critical factors during the extrusion process. This information is used to adjust the process in real-time to optimize output and minimize waste.

4. Regular Maintenance and Cleaning

Regular maintenance and cleaning of extrusion equipment are essential to ensure that it operates at maximum efficiency. This includes cleaning the extruder barrel and die, replacing worn or damaged parts, and ensuring that all equipment is properly lubricated and adjusted. Regular maintenance can also help prevent downtime and costly repairs.

5. Training and Education

Proper training and education of personnel are critical to maintaining an efficient extrusion line. This includes training on proper equipment operation, maintenance, and troubleshooting, as well as education on best practices for optimizing the extrusion process. Training can help prevent errors and reduce the likelihood of downtime and production waste.

Conclusion

Improving extrusion line efficiency can have a significant impact on your bottom line. By choosing the right equipment, optimizing material usage, using advanced process control systems, regular maintenance and cleaning, and providing proper training and education to personnel, you can minimize waste and downtime and maximize production output. By implementing these tips, you can ensure that your extrusion line operates at maximum efficiency, which can help you stay competitive in today's fast-paced manufacturing environment.