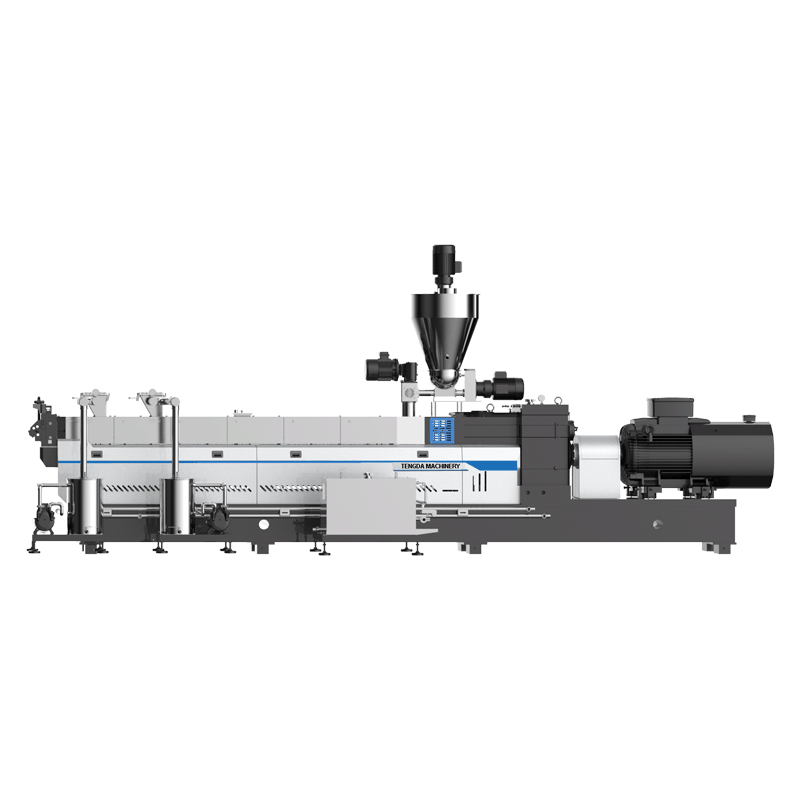

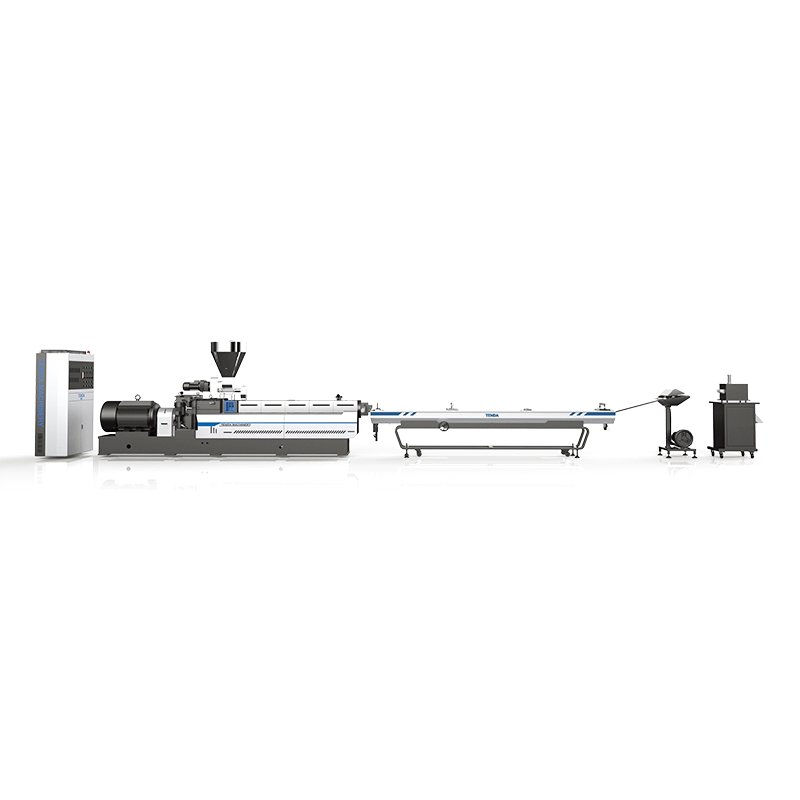

Introduction and application of twin-screw extruder

1. Feeding system: including hopper, stirring motor and feeding motor. It can prevent material accumulation and facilitate its smooth entry into the feed port.

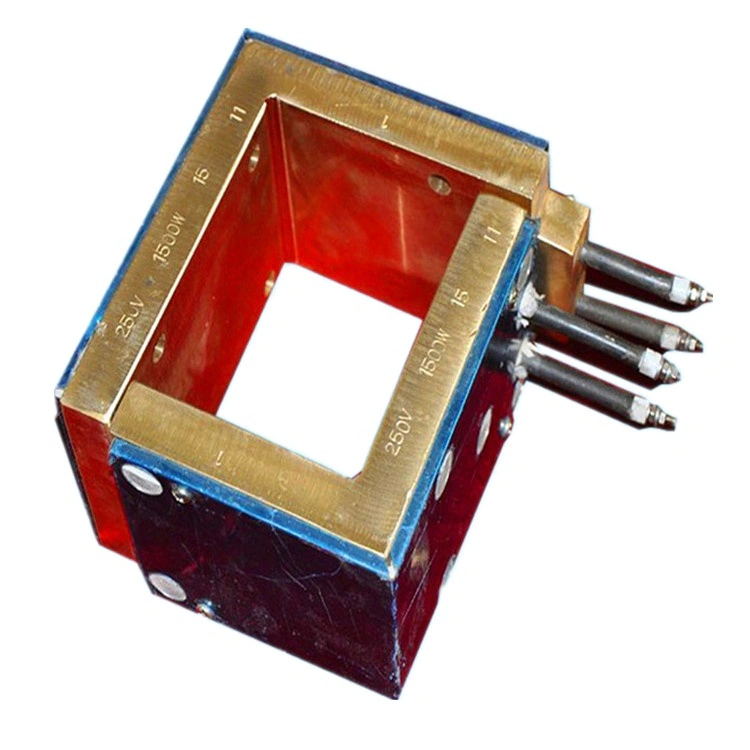

2. External heating system: mainly use the heating rod and cylinder to heat the material efficiently and promote plasticization.

3. Cooling system: The heat exchange system composed of heat transfer oil or water is used to reduce the heat of the fuselage, so as to effectively control the temperature of the cylinder.

4. Hydraulic screen changing system: Use replaceable filter screen to intercept impurities, improve the degree of plasticization, and ensure the uniformity and stability of the quality of the output materials.

5. Vacuum system: extract moisture and other low molecular volatiles from the material.

6. Electronic control system: responsible for monitoring and controlling the relevant equipment of the main and auxiliary material system.

7. Screw system: an important part of the twin-screw extruder, which can be divided into a conveying section, a melting section (exhaust port), a plasticizing section (vacuum port), and a discharge section.

The screw system mainly completes the plasticization and conveying process of the material, which has a great influence on the performance and quality of the finished product. The screw parameter settings of different models and equipment from different manufacturers are different, so it needs to be paid attention to.

Segmentation of the screw

The screw system of parallel twin-screw extruder is generally divided into 4 sections: conveying section, melting section (exhaust port), plasticizing section (vacuum port), and discharge section.

1. Conveying section: it is used to convey materials and prevent material return.

2. Melting section: This section makes the materials fully melt and mix through heat conduction and frictional shearing.

3. Plasticizing section: to further melt and mix the components of the material, with the function of distributive and dispersive mixing.

4. Discharging section: Conveying and pressurizing to form a certain pressure to make the materials more compact and further mixed to achieve the purpose of extrusion and granulation.

Nanjing Tengda Machinery Co., Ltd. is recognized as one of the leading manufacturer of in China.Trust in us and make Nanjing Tengda Machinery Co., Ltd. your Application supplier. Our products will bring more economic value to you.

If you have any issues with your Application, you will have to call the experts at TENGDA Extruder Machine Manufacturers to assist you. Any of your enquiry is warmly welcomed.

Nanjing Tengda Machinery Co., Ltd. incorporates average length of the workweek, average growth in number of small businesses, startup per capita, average of growth of business revenues, five-year business survival rate, industry variety, entrepreneurship index and how digital a state is.

Nanjing Tengda Machinery Co., Ltd. usees sentiment analysis to understand what their customers care about and leverage that information to reposition their products, create new content or even provide new products and services.