Introduction of feeding system for plastic extruder

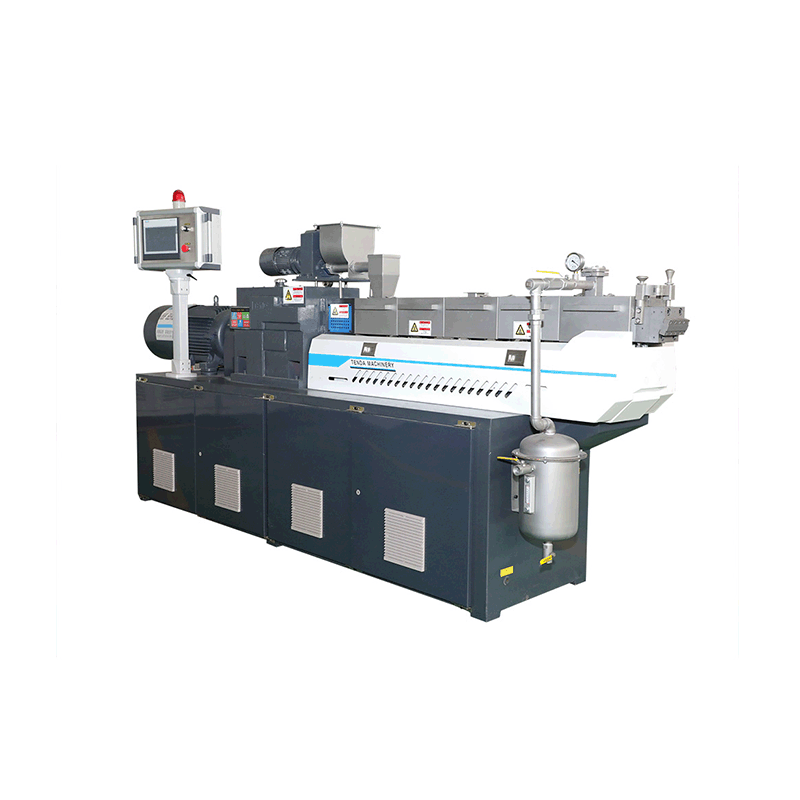

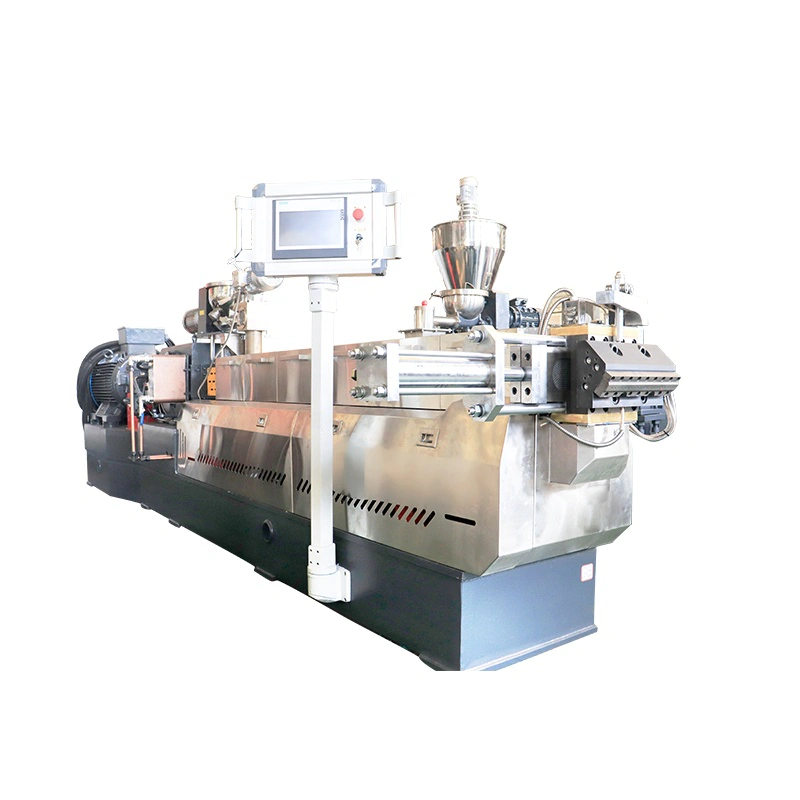

According to the feeding method, plastic extruders can be divided into cold-feed plastic extruders and hot-feed plastic extruders. The difference between these two plastic extruders is whether the feeding system of the equipment is a forced feeding system.

The feeding port of the cold feed plastic extruder has a forced feeding roller, and when the temperature of the equipment rises to the temperature we need, it can be fed in the feeding port of the plastic extruder. Raw materials are fed through the forced feeding port to keep the screw barrel pressure of the extruder

In a constant state, especially after the pressure of the extruder die is constant, it will be uniform and stable during extrusion, and the product size will be uniform.

For the feeding system of the hot-feed plastic extruder, the feeding is directly driven by the screw. This method is cheap and cost-effective, but for the extruder used for extrusion molding, this method Advanced plastic extruders are very unsuitable for extruding finished products.

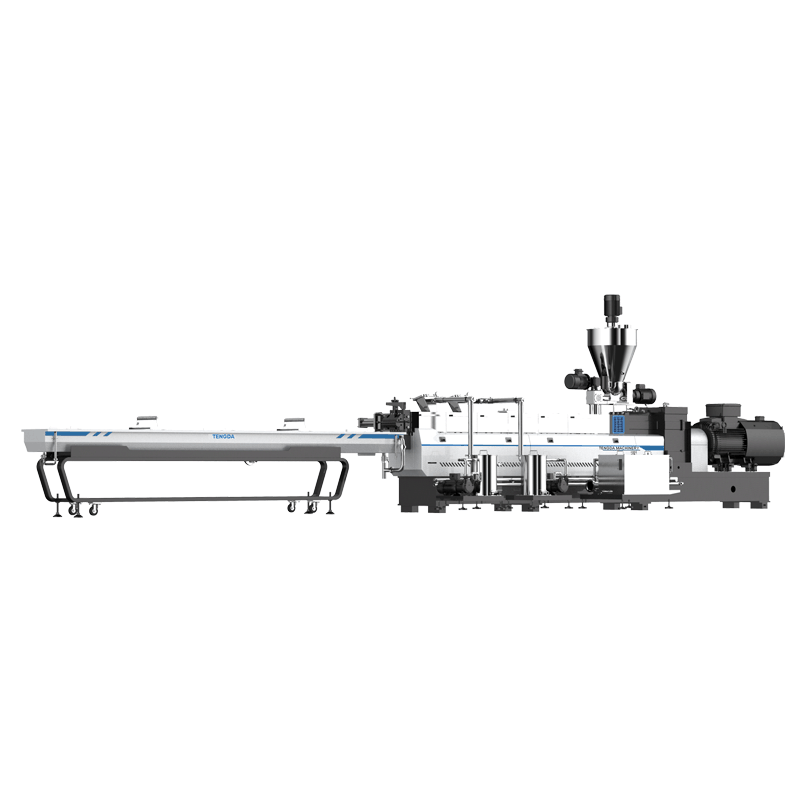

Looking for a producer to fix your Application problems? Then contact the Application experts at Nanjing Tengda Machinery Co., Ltd., offering a wide range of products across the global market. Visit TENGDA Extruder Machine Manufacturers to find our best offer!

Review Nanjing Tengda Machinery Co., Ltd.'s progress at regular intervals, so we can continue with the strategies that work well and change or eliminate the ones that don't give the results we are looking for.

Nanjing Tengda Machinery Co., Ltd. employs a group of professional staff, enhancing the function of Application.