Introduction of plastic modified granulator

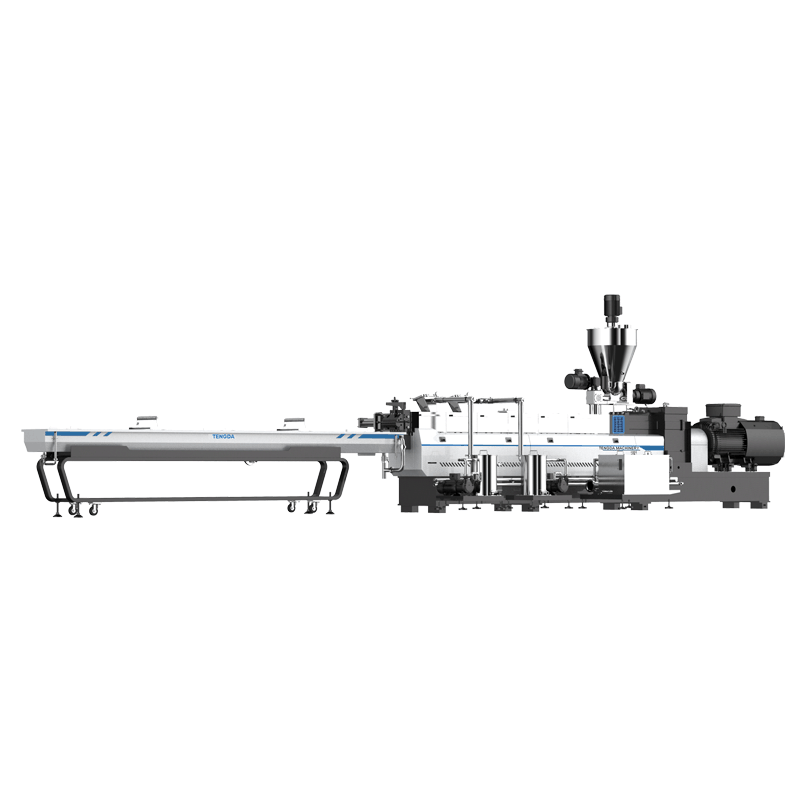

Basic introduction of plastic modified granulator of twin-screw extrusion granulator: The twin-screw granulator has a good plasticizing effect on the material through the shearing combination of many screw blocks, and by changing the combination of screw elements Can be suitable for various materials. The basic structure of plastic modified granulator: 1. Twin-screw main machine 2. Water-stretching head 3. Conveyor belt 4. Pelletizer 5. Silo.

The twin-screw extruder starts with two more effective cleaning agents: mixture: HDPE + water + decontamination powder. The HDPE was fed into the screw at the melt temperature at the usual rate. The decontamination powder is stirred into a slurry with water in a bucket, and the slurry is slowly added from the main feeding port. These slurries impact, rub, and clean the screw due to foaming. Mixture: 50% HDPE + 50% diatomaceous earth.

Nanjing Tengda Machinery Co., Ltd. is different from other companies as we provide timely and unique services to our respected clients.

For more advice on tips, please visit our website TENGDA Extruder Machine Manufacturers. Do not hesitate to contact us if you are interested.

According to the latest social survey, more than 50 percent of consumers (across all age demographics) follow a brand before purchasing a product. Therefore, TENGDA's content can make or break a customer's decision to conduct business with you.