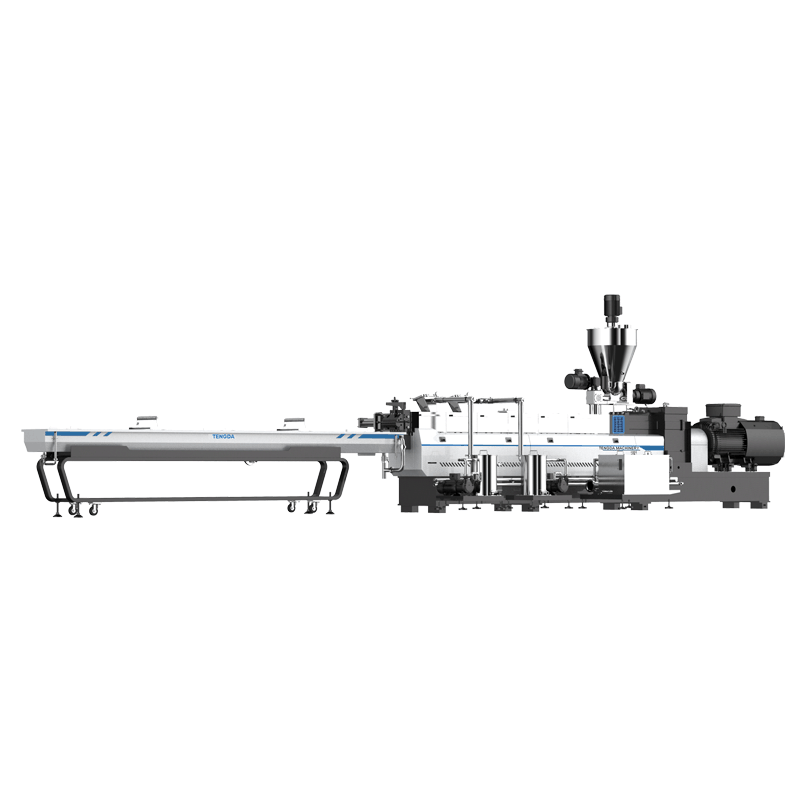

Kunshan masterbatch granulator

The masterbatch granulator copolymerization first dissolves the nano-CaCO3 powder in the monomer, forms a very thin polymer film layer on the surface of the CaCO3 powder, and then initiates its polymerization to form a well-dispersed nano-CaCO3/composite material; or in flexible polymerization The polymer monomer is first dissolved in a compound or an appropriate solvent, and then the nano-CaCO3 powder is added, and then the monomer polymerization is initiated, and the polymer is gradually adsorbed on the surface of the CaCO3 nano-powder. The change of the physicochemical and charging properties of the polymer directionally adsorbed on the surface of the calcium carbonate powder makes the nanoscale calcium carbonate powder better and stably disperse in the formed matrix of the cutting polymer composite material. This method has been successfully used. There are many nano-calcium carbonate modified plastics.

The single-screw granulator is a blending process that mixes the nano-CaC03 powder treated with epi-core modifiers such as coupling agent, color masterbatch granulator surfactant and compatibilizer as filler and extender. , in order to improve the tightness of the filler and the matrix plastic resin. Such as modified polyolefins, blending and filling modified polypropylene (PP), PPI ethylene propylene rubber (EPDM), polyethylene (PE), polyvinyl chloride (PVC), polysaccharide (PU), montane styrene (PS), propylene, butadiene copolymer (ABS) and other resins. Many fruitful products have been reported. 3.1 Modified polypropylene (PP) Nano-calcium carbonate modified PP has achieved results. The tensile strength of PP modified by nano calcium carbonate is increased by 1 times, and the impact toughness is increased by 3.5 times. The PP modified by this technology can be made into engineering plastic pipes for holding irrigation. Zibo City Information Center reported that special interfacial activators were selected and the corresponding additives were optimized. The activated nano-CaCO3 powders were filled with modified PP, and the particles were first adjusted, and then processed and formed by extrusion, injection and other processes, or they could be directly extruded and continuously Calendered into sheets. The modified PP composite material has a large filling amount, good toughness and good processing fluidity. It can be used for home appliance accessories such as washing machines.

As we have known for quite some time, the success of TENGDA in the future will depend greatly on our ability to strike a balance between valuable human insight and interaction with technology.

To know more about Application extruder machine manufacturers, visit TENGDA Extruder Machine Manufacturers for more reviews, tips and advice. Nanjing Tengda Machinery Co., Ltd. won't let you down for your options. visit!

is something that has been around for a few decades now, enjoying it's heyday back in the plastic extruder machine manufacturers.

The group's Quality Systems Manager (QSM) is responsible for ensuring that Nanjing Tengda Machinery Co., Ltd. has in place systems that guarantee quality throughout the Group.