Manufacturing with Sheet Extruders: Pros and Cons

Manufacturing with Sheet Extruders: Pros and Cons

Sheet extrusion is an essential process in manufacturing industries. It is a technique used to make flat sheets or films of thermoplastics by forcing them through a die into a specific shape. Sheet extrusion can be done using various techniques. One of the most popular techniques used for sheet extrusion is the use of sheet extruders. In this article, we will discuss the pros and cons of manufacturing with sheet extruders.

What is Sheet Extrusion?

Sheet extrusion is a method used to produce plastic sheets and films. The process involves melting plastic pellets and extruding them through a die to form a flat sheet. Sheet extrusion is popular for its ability to produce large quantities of plastic sheets quickly and efficiently. The thickness of the sheet can be controlled by adjusting the distance between the rollers.

Types of Sheet Extruders

Sheet extruders come in different types, and each is suitable for specific applications. Some common types of sheet extruders include:

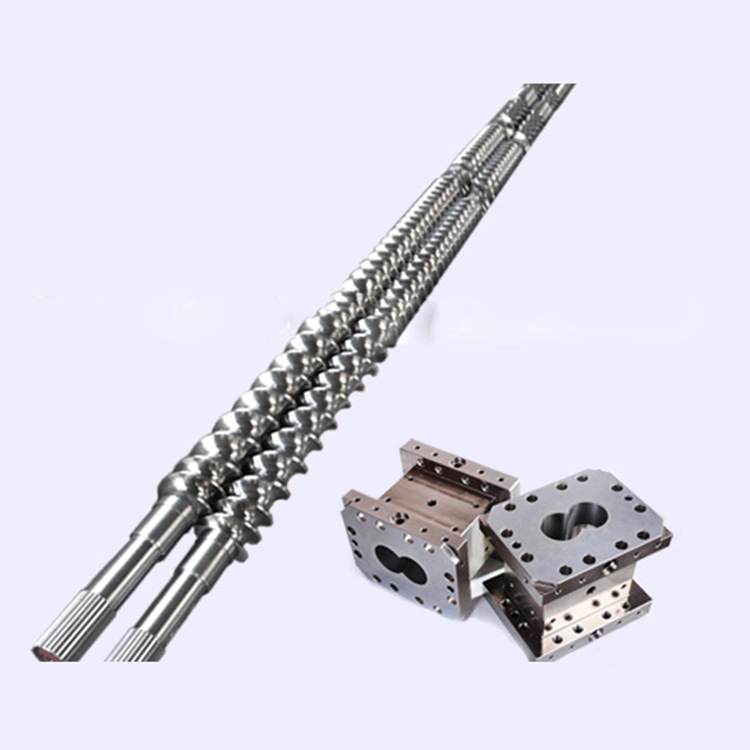

1. Single Screw Extruders: These extruders consist of a single screw which rotates and pushes the molten plastic material through the die to form the sheet.

2. Twin Screw Extruders: These extruders use two screws that rotate in opposite directions, and they are suitable for processing a wide range of materials.

3. Co-extruders: These extruders have multiple extrusion heads that can produce multi-layered sheets.

Pros of Manufacturing with Sheet Extruders:

1. High Production Volume: Sheet extruders are suitable for high-volume production of plastic sheets. With sheet extruders, multiple sheets can be produced at the same time, which results in high productivity and efficiency.

2. Flexibility: Sheet extruders are flexible and can process different types of materials, such as PVC, PET, and Polypropylene. As a result, manufacturers can use sheet extruders to produce a wide range of products.

3. Consistency: Sheet extruders produce consistent plastic sheets, which meet the required specifications. The thickness of the sheet can be controlled accurately, and the sheet's surface is uniform.

4. Easy to Operate: Sheet extruders are easy to operate and require minimal training. Once the extruder is set up, the manufacturing process is automated, and the machine can run continuously.

5. Cost-effective: Sheet extruders are cost-effective compared to other methods of producing plastic sheets. The machines are durable and require minimal maintenance. They can also run for extended periods without needing to be shut down for maintenance.

Cons of Manufacturing with Sheet Extruders:

1. Initial Capital Investment: Sheet extruders are expensive machines, and manufacturers need to invest a significant amount of money to purchase them. The cost of maintenance and repair can also be high.

2. Limited Product Variety: Sheet extruders are limited in the types of products they can produce. Manufacturers can only produce flat sheets or films, and they require additional processing to produce more complex products.

3. Energy Consumption: Sheet extruders consume a lot of energy, and this can increase the manufacturing cost. However, modern sheet extruders have energy-saving features that reduce energy consumption.

4. Difficulty in Changing Materials: Changing materials in a sheet extruder can be challenging and time-consuming. Manufacturers need to flush out the previous material from the machine and ensure that the machine is clean before adding the new material.

5. Size Limitations: Sheet extruders are limited in the size of the sheet they can produce. This can pose a challenge for manufacturers who need to produce large plastic sheets.

Conclusion:

Sheet extruders are essential machines in plastic sheet and film manufacturing. They offer several advantages, such as high production volume, flexibility, consistency, ease of operation, and cost-effectiveness. Sheet extruders also have some disadvantages, such as the high capital investment, limited product variety, energy consumption, difficulty in changing materials, and size limitations. Manufacturers, therefore, need to evaluate their needs before investing in sheet extruders and choose the type that best suits their requirements.

Nanjing Tengda Machinery Co., Ltd. promises that we will manufature our products in accordance with the strictest quality standards.

If you want to know more about finding the proper for extruder machine manufacturers solutions, visit TENGDA Extruder Machine Manufacturers.

The first machine to produce plastic extruder machine manufacturers, the extruder machine manufacturers Application was invented in plastic extruder machine manufacturers in extruder machine manufacturers by plastic extruder machine manufacturers and was subsequently improved.

Being focused on the goals of Application, our team, and most importantly, ourselves is critical to long-term success.