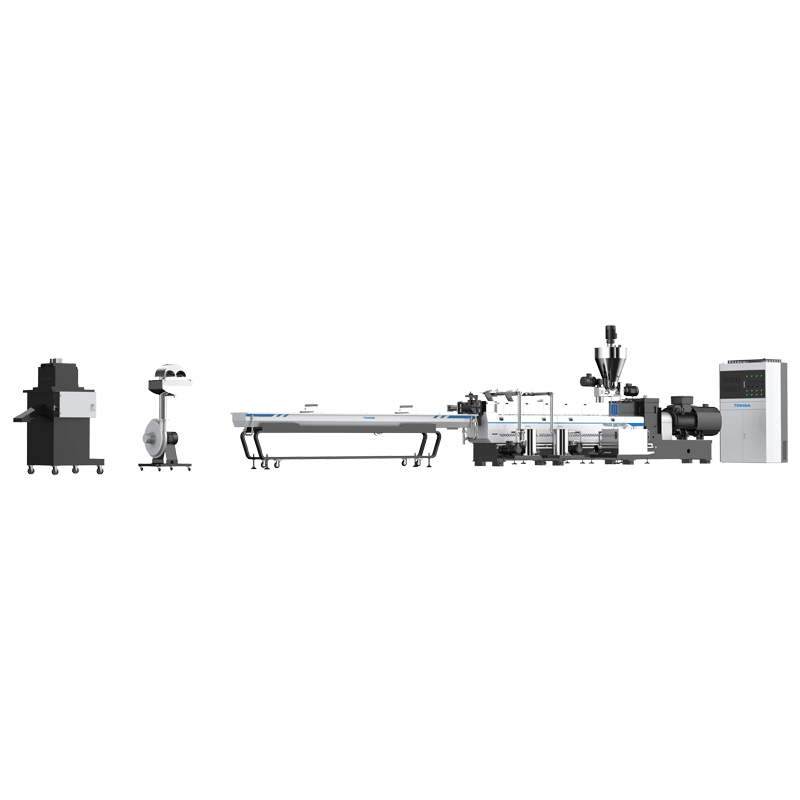

Masterbatch granulator production process

The production process of masterbatch granulator

The color masterbatch is a necessary colorant in plastic products, and the principle of the color masterbatch granulator is to change the application of the color masterbatch in plastic products through the complex structure inside the plastic, so that the gravitational interaction between the molecules , becoming a tough plastic. The screw of the masterbatch granulator adopts the principle of building blocks, which can be required according to the processing material system and process. Its aspect ratio, barrel structure, screw arrangement, screen changing structure, exhaust quantity and position, feeding method, electrical control Modes, etc., can be optimized and reasonably configured. The production process of the masterbatch granulator can be divided into 7 steps:

1. Weighing: Toner, carrier, lubricant, dispersant and other additives are weighed according to the weight required by the process, and the higher the accuracy, the better.

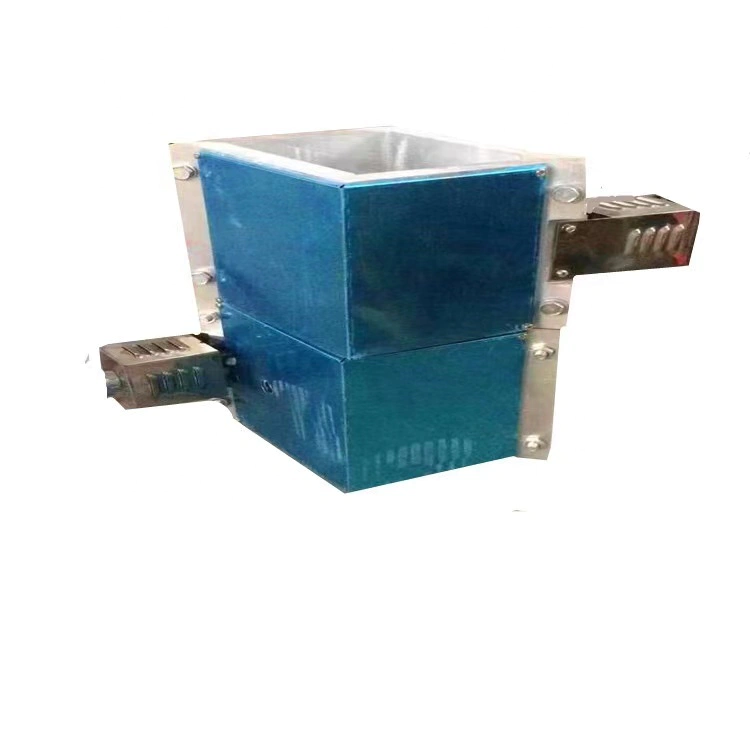

2. Stirring: Put the weighed auxiliaries into the high mixer in order according to the technological process.

3. Extruder: Set according to the temperature of the carrier of the masterbatch, keep it warm for a certain period of time before starting the machine, and increase the speed from slow to fast.

4. Pull bar: After the die is discharged, hold the material bar by hand and move it to the pelletizer at a constant speed, and pass through the dryer or dryer in the middle.

5 Cut and pull: When the material strip reaches the feed port of the pelletizer, slowly increase the pelletizer speed.

6. Packing: Packing according to customer's needs.

7. Follow-up adjustment: After the whole set of equipment is running normally for a period of time, adjust the speed to the normal production speed in turn. Masterbatch Granulator

Nanjing Tengda Machinery Co., Ltd. specializes in undertaking corporate offers to cater the needs of different companies.

Reach us at TENGDA Extruder Machine Manufacturers. We'll always try to give you the BEST deal on . If we can't, we'll at least give you some hel pful advice. Please use our experience!

Technology upgrades can pay for themselves quickly by improving Application and enabling employees to accomplish more in less time. It may be time to focus on plastic extruder machine manufacturers to ensure they run smoothly and efficiently.