Maximizing Throughput with High-Speed Extruder Equipment

Maximizing Throughput with High-Speed Extruder Equipment

For companies involved in the extrusion industry, the ability to increase throughput and reduce production costs is critical to success in a highly competitive market. One of the most effective ways to achieve this is by maximizing the efficiency of high-speed extruder equipment. Such equipment has the potential to significantly boost production capacity, while also improving product quality and consistency. In this article, we will explore how companies can maximize throughput with high-speed extruder equipment.

Understanding the Benefits of High-Speed Extruder Equipment

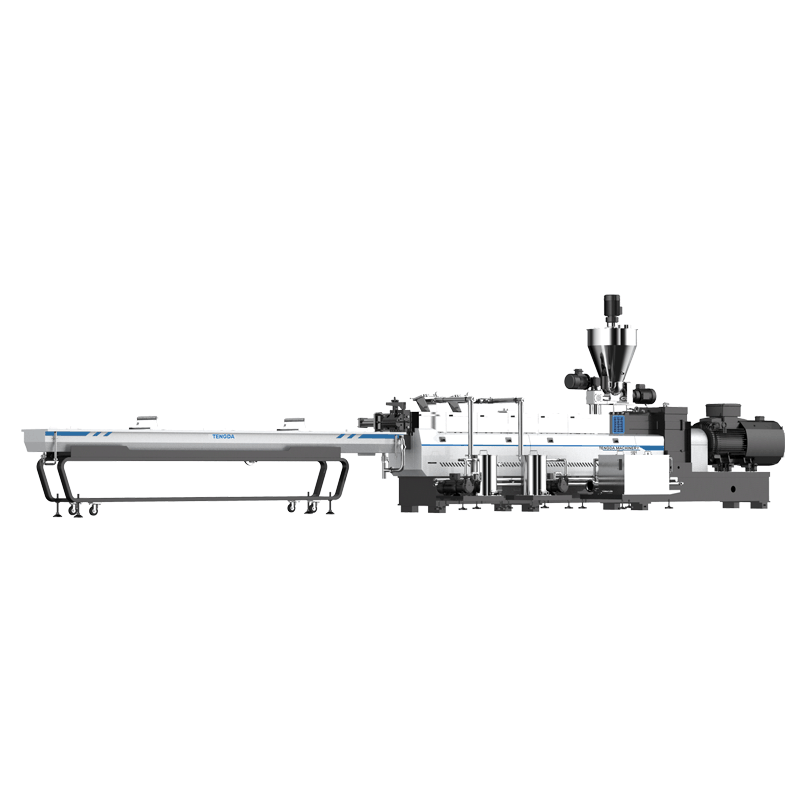

High-speed extruder equipment is designed to handle a wide range of materials including plastics, rubber, and other types of polymers. By using state-of-the-art processing technology, it can produce products at a much faster pace than traditional extruders. It is this ability to increase production volumes that make high-speed equipment such an attractive proposition for businesses looking to improve their operational efficiency.

In addition to improved production volumes, high-speed extrusion also offers other benefits. For example, it helps to reduce energy consumption and material waste. Furthermore, high-speed extruders have improved processing capabilities, resulting in a higher quality end product.

Subheading: Utilizing Advanced Control Systems

One key way of maximizing the throughput of high-speed extruder equipment is by utilizing advanced control systems. These systems enable manufacturers to monitor and adjust the system for maximum process efficiency. They can provide real-time data on equipment performance and give operators the ability to make adjustments to parameters such as temperature, pressure, and material flow.

These control systems can also be used to automate the extrusion process, reducing the need for manual intervention. This can help to improve consistency and precision in the production process. As a result, manufacturers can produce products faster and more efficiently, leading to higher overall throughput.

Subheading: Improving Extruder Design

Another key factor in maximizing throughput is improving extruder design. Modern high-speed extruders are designed with features that increase performance, such as improved screw geometry, heating and cooling systems, and screw materials. By optimizing these features, manufacturers can extract more value from their equipment, and achieve higher production volumes.

Additionally, by utilizing advanced extruder designs, manufacturers can also reduce energy consumption and maintenance costs. This can lead to significant cost savings over the long term. By investing in high-quality equipment, companies can not only improve their overall production capacity but also reduce their operational costs.

Subheading: Improving Material Handling

High-speed extruder equipment requires materials to be fed into the system at a consistent rate. Any fluctuations in the material flow can disrupt the process and reduce the efficiency of the equipment. Therefore, it is essential to have a reliable and efficient material handling system in place.

One way of improving material handling is by installing automatic feeders that can deliver materials to the extruder at a consistent rate. These systems can be programmed to operate automatically, ensuring that the material flow remains constant and predictable. Additionally, automated material handling systems can improve safety and reduce the risk of workplace injuries.

Subheading: Paying Attention To Cleaning

Maintaining high-speed extruder equipment so that it operates at peak efficiency is essential. Part of this routine maintenance is keeping the equipment clean. Deposits of materials left behind during the extrusion process can impact the performance of the equipment, reducing its overall throughput. A cleaning schedule should be put in place to ensure that the equipment is cleaned regularly.

Furthermore, the type of cleaning solution used can have an impact on the equipments overall efficiency. Cleaning solutions that are too harsh can damage materials and components, leading to a reduction in the lifespan of the equipment. Manufacturers should select cleaning solutions that are specifically designed for the equipment being used.

Conclusion

Maximizing throughput with high-speed extruder equipment requires a holistic approach. By optimizing equipment design, material handling, and maintenance, manufacturers can extract more value from their equipment. Additionally, advanced control systems can provide real-time data on equipment performance, enabling operators to adjust parameters for maximum efficiency. By taking these steps, manufacturers can increase production volumes, improve product quality and consistency, and reduce operational costs.

Application are all following the most compatible manufacturing regulations.

Satisfying our customers with the appropriate level of quality is a primary goal and a fundamental element as Application of our business mission.

So, what's a manufacturer to do? Familiarize ourselves with producing Application in various technologies.