Operating Specifications for Twin Screw Extruders

When using a twin-screw extruder, it is necessary to check the inner seal of the barrel and the hopper first, and also check whether there is any foreign matter inside. If any problem is found, it should be dealt with in time. The screw should be turned on at a low speed, and the idling time should not be too long. It should be carried out in accordance with the requirements of the twin-screw extruder manufacturer. The purity of each batch of materials should be checked, and no other debris should be mixed into it. When there is a problem with the temperature display, use a mercury thermometer to measure the mold and barrel to see if the temperature meets the requirements.

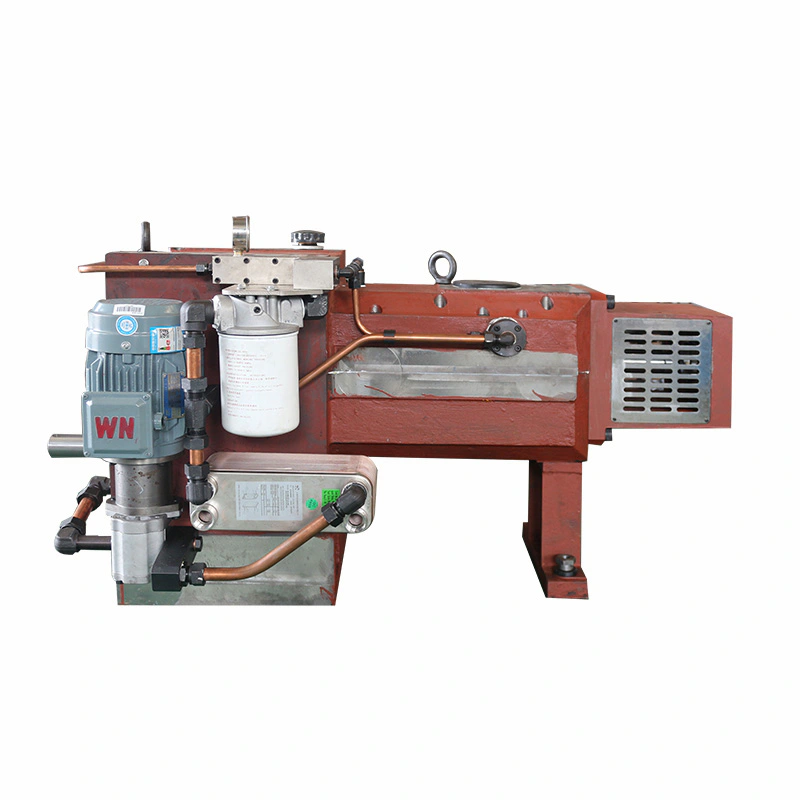

Check all parts of the equipment in a certain order. If it is found that the coupling does not rotate when cranking, or there is an abnormal sound when the screw is rotating, remove the screw and re-install it. assembled. When cleaning the screw, do not use steel knives, but copper brushes can be used for cleaning. When replacing bearings, adjust the position of the spring and do not install it in a wrong position. When removing the screw, use special tools and follow the corresponding sequence. After removing the screw, clean up the residual material while it is hot, but do not remove the components.

Whenever you grab your remote and turn on the TV, there are numerous ads promoting Application and offering for plastic extruder machine manufacturers extracts, which are said to boost extruder machine manufacturers.

Our knowledgeable loss prevention experts can help commercial customers reduce losses in Application.

Millions of women across the world suffer from plastic extruder machine manufacturers. Are you also one of them who suffer from acne problem? now you will see some hope in Nanjing Tengda Machinery Co., Ltd.'s offer of . Click TENGDA Extruder Machine Manufacturers to know more.