Optimizing the Output of Your PVC Extruder Machine

Optimizing the Output of Your PVC Extruder Machine

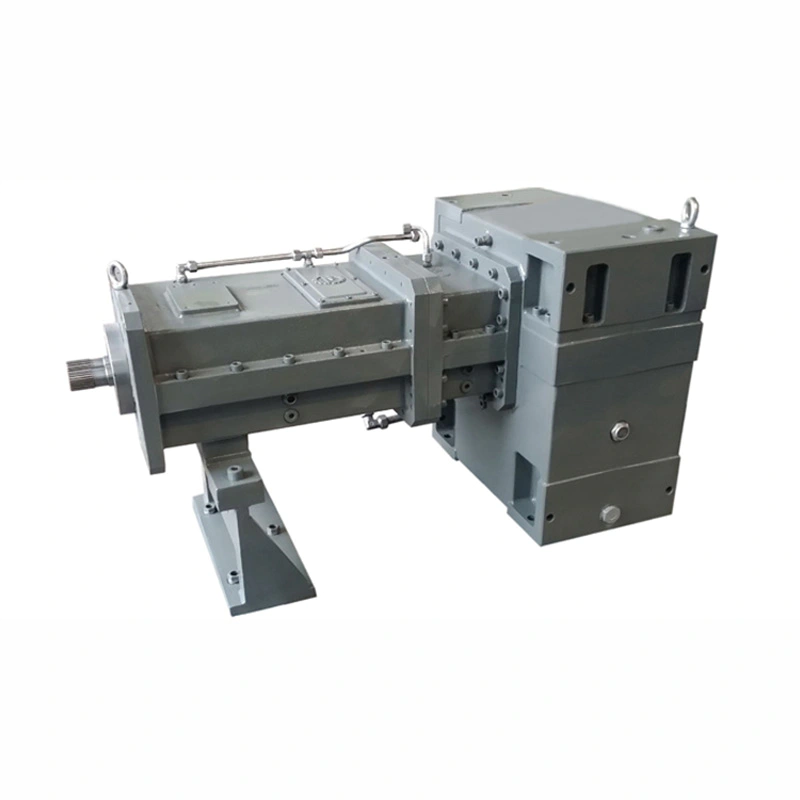

PVC extruder machines play an important role in the manufacturing of a range of products all over the world. From pipes, wire insulations, cable coatings, to window profiles and many other products, the PVC extrusion process has come a long way in the past few decades. However, the process is still complex and requires careful attention to detail.

If youre a manufacturer working with PVC extruder machines, youre probably looking for ways to optimize your output. In this article, well explore several key areas you can focus on to maximize your efficiency and improve the quality of your products.

Subheading 1 C Understanding Your PVC Extruder Machine

Before you can begin optimizing your machine, its essential to understand how it works and what its capabilities are. PVC extruder machines come in all shapes and sizes, depending on the type of product being manufactured and the volume of output required. Some machines can produce up to 10,000 kg/hour, while others are designed for smaller, batch-oriented production.

Here are some essential features to review when evaluating your PVC extruder machine:

- Screw diameter

- Barrel length

- L/D ratio

- Extruder speed

- Motor power

- Temperature control

Understanding these features, testing them, and knowing how to operate them will aid in optimizing your machine's output.

Subheading 2 C Material Cost Savings

One of the biggest expenses in PVC extrusion is material cost, so any reduction in waste can lead to significant savings. When optimizing your machine, its important to consider ways to minimize your scrap rate.

One common way to reduce scrap is by using a color masterbatch instead of colored compounds. Color masterbatches are highly concentrated pigments that are added to the base material during the extrusion process. By using a masterbatch instead of a pre-colored compound, manufacturers can reduce the number of different compounds they need to use and store, leading to less material waste.

Another way to optimize material usage is by strictly controlling the temperature and cooling process of the PVC extrusion. Consistent temperatures, cooling rates, and other factors will reduce errors due to heat variations.

Subheading 3 C Consistency in Production

One of the primary aims of optimizing your PVC extruder process is to enhance the quality of your final product. Consistency in production is key to achieving this.

To produce PVC products that meet customer specifications every time, its crucial to have a consistent process in place. This means having standard operating procedures for the machine operation, maintenance and calibrations. Here are some areas to consider when ensuring consistency in production:

- Cleaning and maintenance schedule

- Machine operating procedures

- Staff training and development

- Preventative maintenance

- Calibration

By establishing a consistent process, you can not only improve the quality of your products, but also reduce machine maintenance time and unexpected machine downtime.

Subheading 4 C Quality Assurance

PVC extrusion requires careful and precise monitoring to ensure your product meets customer satisfaction. Quality assurance (QA) is the process of ensuring the final product meets customer expectations. Quality assurance practices include:

- Process monitoring through recording and reviewing data that is collected through sensors and other mechanisms.

- Compliance testing to verify that your products meet specified industry standards.

- Evaluation of the product by visual inspection or by laboratory testing to examine the product's properties.

- Consistent calibration of the machine to meet regulated with industry-specific standards

When carrying out QA procedures related to the products, you can avoid costly recalls and fines.

Subheading 5 C Training Your Staff

Last but not least, staff training is often overlooked when it comes to PVC extrusion optimization. However, Operating PVC extruder machines requires careful safety checks, efficient machine operating practices, reliable data monitoring, and consistent machine maintenance. Without proper training, your staff may not be aware of all the details and nuances required to optimize your PVC extruder machine. Here are some training needs to consider:

- Safety procedures

- Operational training

- Data analysis

- Preventive maintenance

- Problem-solving skills

Training staff allows for the creation of a culture of safety and high employee morale

Conclusion

Overall, there are a variety of different ways to optimize your PVC extruder machine process. By focusing on areas such as understanding your machine, cost savings, consistency, quality assurance, and training your staff, you can maximize your overall efficiency and product quality while reducing material waste. With continued focus and refinement, you can ensure your PVC extruder process is reliable and efficient.

Nanjing Tengda Machinery Co., Ltd. specializes in undertaking corporate offers to cater the needs of different companies.

Nanjing Tengda Machinery Co., Ltd. is proud to be recognized as some of the most important and influential providers for global customers.Visit us at TENGDA Extruder Machine Manufacturers.

The unique connections between Applicationmanufacturing and customers happen when you find ways to relate on a more personal and engaging level that goes beyond a product.

Based on the Application, here are the top compliance challenges businesses face, and what you can do to make them easier on ourselves.

plastic extruder machine manufacturers Application is characterized by various advantages, such as extruder machine manufacturers, plastic extruder machine manufacturers and extruder machine manufacturers, which is not the case with other Application.