Overview and classification of extruders

Overview and classification of extruders.

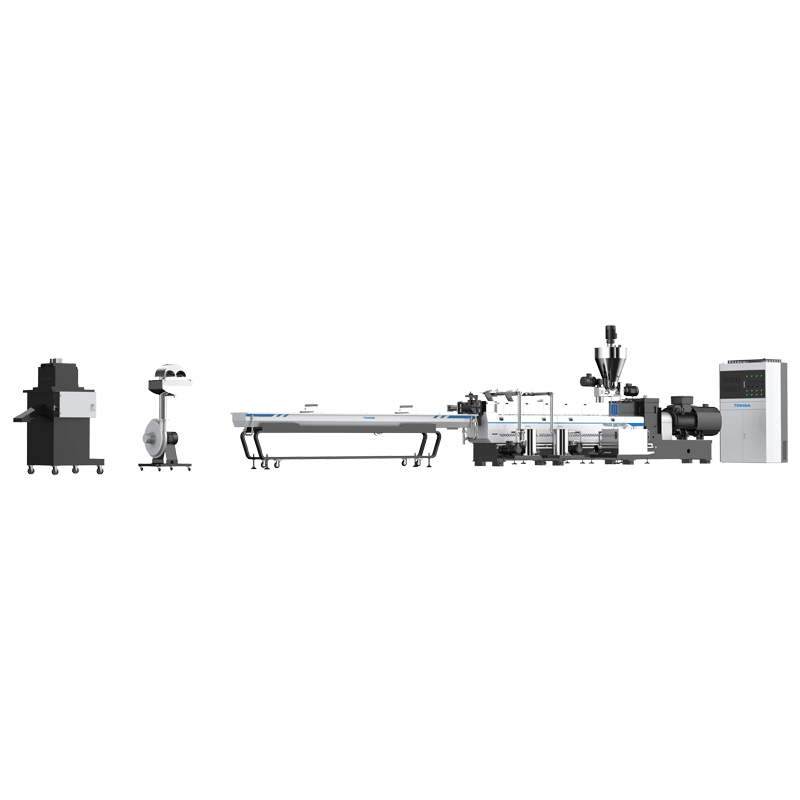

The extruder can be divided into continuous extrusion and discontinuous extrusion according to the type of function. Plastic extruder is also a type of plastic machinery. According to the angle between the material flow direction of the extruder and the center line of the screw, the extruder can be divided into an oblique die (the angle is 120°) and a right angle die. The nose shell is bolted to the fuselage. The mold in the machine head has a mold core seat, which is fixed at the wire inlet of the machine head with a nut. The mold core is installed in front of the mold core seat, and the center of the mold core and the mold core seat has a hole through the core wire.

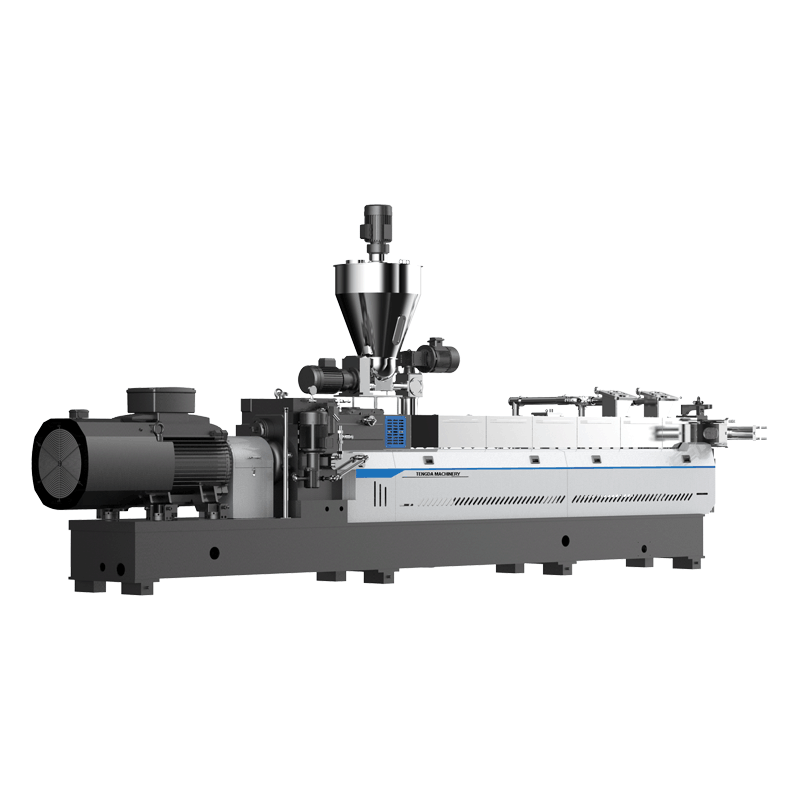

Plastic extruders are divided into twin-screw extruders and single-screw extruders, as well as uncommon multi-screw extruders and non-screw extruders.

The mechanical principle of the extruder.

Add water or suitable liquid to the raw powder and keep stirring. The agitated material is extruded from a perforated die or wire mesh with high extrusion pressure.

Usually, after the material is put into a cylindrical container, the material is extruded with a screw. After using the frequency conversion technology, the pressure can be controlled to select the appropriate line speed.

The principle of single screw extruder.

Generally, the effective length of a single screw is divided into three sections, which are determined according to the diameter, pitch and depth of the screw. Generally, each section is divided by one third.

A line behind the material port is called the conveying section: the material here cannot be plasticized and needs to be preheated and pressed for compaction. The old extrusion theory used to think that the material here was loose, but it was later proved that the material here is actually a solid plug, that is to say, the material here is a solid like a plug after being squeezed, so as long as the conveying task is completed, it is its effect.

The second segment is called the compressed segment. At this time, the volume of the spiral groove gradually decreases from large to small, and the temperature should reach the plasticization level of the material. The compression produced here is from conveying section 3 to 1, called the screw compression ratio -3:1. Some machines are also changed, and the plasticized material enters the third stage.

The third section is the metering section, where the material maintains the plasticizing temperature, but just like a metering pump to deliver the molten material accurately and quantitatively to supply the machine head. At this time, the temperature should not be lower than the plasticizing temperature, which is generally slightly higher.

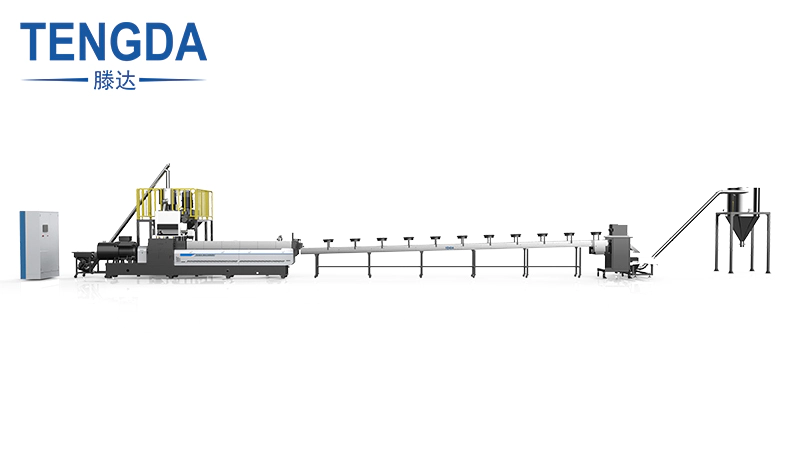

Nanjing Tengda Machinery Co., Ltd. is one of the world’s leading and most-trusted suppliers to the relevant markets.

The guiding vision of Nanjing Tengda Machinery Co., Ltd. is 'Bringing the best to everyone we touch'. By 'The best', we mean the best products, the best people and the best ideas.

Although there are various available in the market (such as plastic extruder machine manufacturers, extruder machine manufacturers, and plastic extruder machine manufacturers), recent study results have made this extruder machine manufacturers Application a preferred Application choice of the people.

Nanjing Tengda Machinery Co., Ltd. are used to coming up with solutions while think about problems, also expressing the whole idea individually.