Several processing plastic categories of plastic granulator

Just mentioned that plastics have a wide range of types. In fact, we can divide their unique effects into two types, namely thermoplastics and thermosetting plastics. The first type, within the whole process temperature range of the plastic granulator, can continuously heat, melt and cool the solidified waste plastics; the latter is that most of them cannot be melted after being solidified by heating or other physical and chemical methods . There are many kinds of thermoplastics that are often seen today, such as polyethylene, polyvinyl chloride, polypropylene, polystyrene, etc., and there are many types of thermosetting plastics, such as phenolic plastics, unsaturated polyester plastics, epoxy plastics, etc. . Because thermosetting plastics, etc., cannot be melted or dissolved after being processed by a plastic granulator, we generally go through various processes for waste thermosetting plastics, such as crushing and grinding, but after this treatment, it is only Used as a filler, waste thermoplastic products can be recycled by melting and plasticizing.

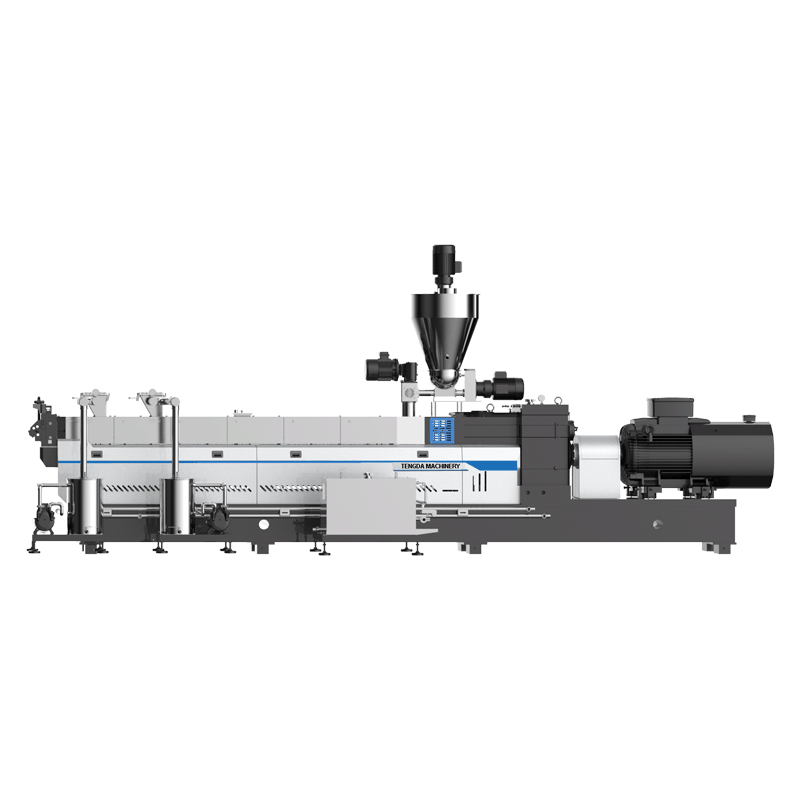

Nanjing Tengda Machinery Co., Ltd. have now decided to extend our company in other countries.

With all the pros and cons of different in mind, click TENGDA Extruder Machine Manufacturers to learn more about and decide which Application option is best for your case.

It is never too late to have a new mindset and to get things moving in the right direction. Choose Nanjing Tengda Machinery Co., Ltd. to be your quality provider.

Nanjing Tengda Machinery Co., Ltd. always think about our customer first. To determine what the consumers would want out of their relationship on social, and work from there.