Sheet Extrusion vs Film Extrusion: Understanding the Differences

Sheet Extrusion vs Film Extrusion: Understanding the Differences

When it comes to plastic manufacturing, two types of extrusion processes are commonly used: sheet extrusion and film extrusion. Although the two processes may seem similar, there are some key differences between them. This article will provide an introduction to sheet extrusion and film extrusion, along with their advantages and disadvantages.

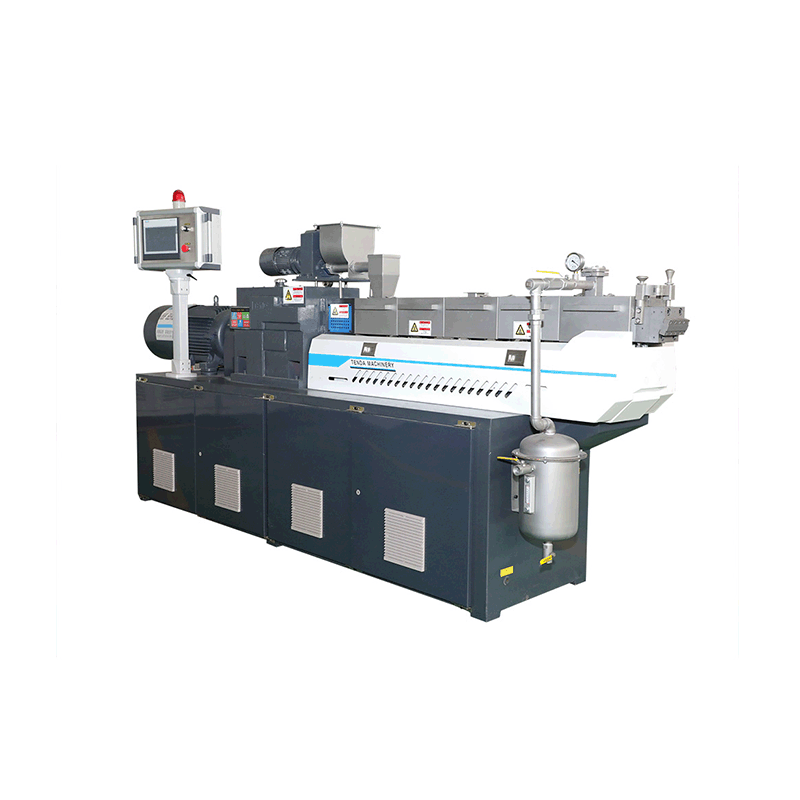

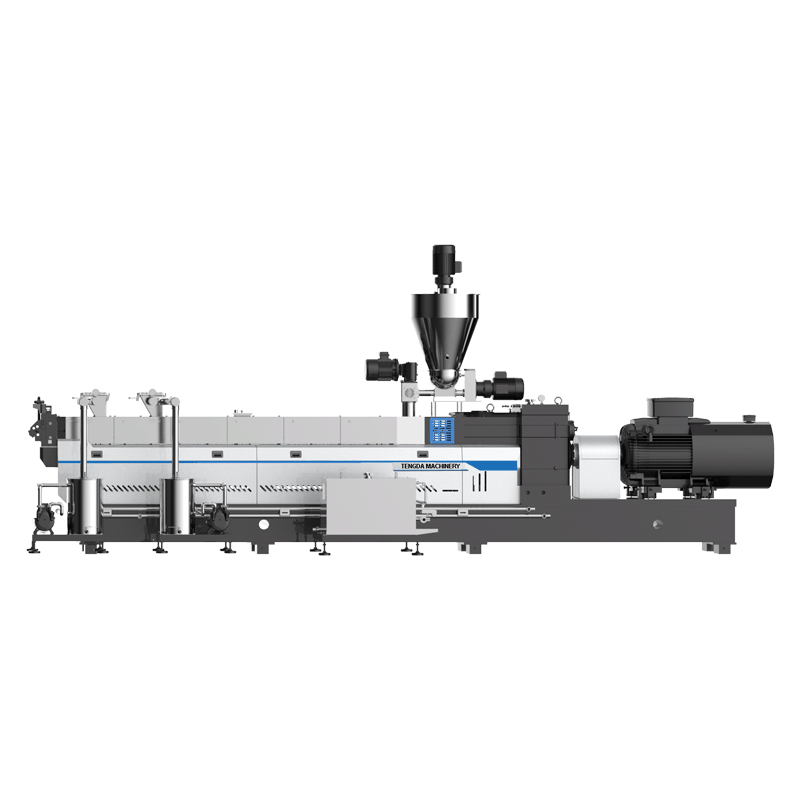

What is Sheet Extrusion?

Sheet extrusion is a plastic manufacturing process that involves extruding a plastic material in a flat sheet form. The process begins by melting plastic pellets or granules within a hopper. The melted plastic is then forced through a die to produce a flat sheet of the desired thickness and width. This sheet can then be cooled, trimmed, and stacked for further processing or delivery.

Sheet extrusion is commonly used to manufacture a wide range of products, including packaging materials, food trays, automotive parts, and medical devices. The process allows for precise thickness control, making it ideal for products that require specific dimensions.

Advantages of Sheet Extrusion

Sheet extrusion offers several advantages over other plastic manufacturing processes:

- Cost-effective: Sheet extrusion is a cost-effective manufacturing process, as it allows for high-volume production of large sheets using relatively few resources.

- Versatile: Sheet extrusion can be used to produce a wide range of products in various shapes and sizes.

- Precise control: The process allows for precise control over the thickness, width, and length of the sheet, making it ideal for products that require exact specifications.

Disadvantages of Sheet Extrusion

Despite its advantages, sheet extrusion does have some limitations:

- Limited thickness: Sheet extrusion is limited in terms of the thickness it can produce. Typically, sheets thicker than 1/8 inch are difficult to produce with this process.

- Limited texture: Sheet extrusion is not typically used to produce textured surfaces, as it produces a smooth, flat sheet.

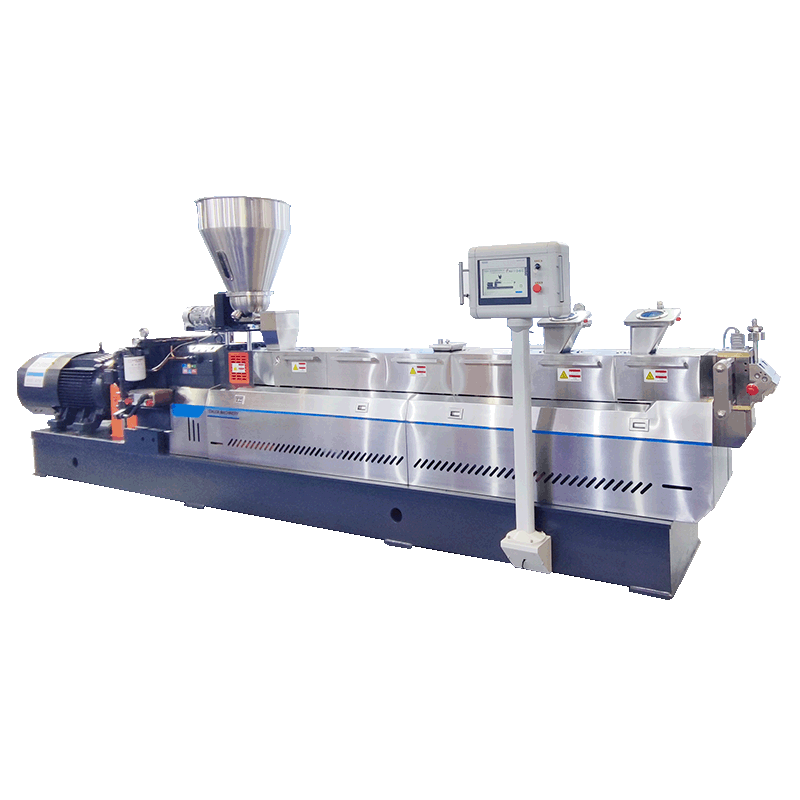

What is Film Extrusion?

Film extrusion is a plastic manufacturing process that involves producing a thin, flexible film from melted plastic. The process begins by melting plastic pellets or granules within a hopper. The melted plastic is then forced through a die to produce a film of the desired width, thickness, and length. The film can then be cooled, trimmed, and rolled for further processing or delivery.

Film extrusion is commonly used to manufacture a wide range of products, including plastic bags, shrink wrap, and food packaging. The process allows for the production of thin, flexible films that can be easily wrapped around products of various shapes and sizes.

Advantages of Film Extrusion

Film extrusion offers several advantages over other plastic manufacturing processes:

- Lightweight: Film extruded products are lightweight, making them ideal for applications where weight matters.

- Flexible: The process can produce films that are thin and flexible, making them suitable for wrapping around a range of products.

- Economical: Film extruded products are cost-effective to manufacture, making them ideal for high volume productions.

Disadvantages of Film Extrusion

Despite its advantages, film extrusion does have some limitations:

- Limited thickness: Film extrusion is limited in terms of producing thicker films. Films thicker than 0.5mm are difficult to produce with this process.

- Limited stiffness: Film extrusion produces a flexible film, which may not provide enough stiffness for some applications.

Sheet Extrusion vs Film Extrusion: Key Differences

Although sheet extrusion and film extrusion may seem similar, there are some key differences between the processes:

- Thickness: Sheet extrusion can produce thicker sheets compared to film extrusion. Sheets can be up to 1/2 inch thick, while film extruded products are usually less than 0.5mm.

- Surface texture: Sheet extrusion can produce products with textured surfaces, while film extrusion typically produces smooth, flat films.

- Applications: Sheet extrusion is suitable for products that require precise dimensions, while film extrusion is suited to products that require a thin, flexible covering.

Conclusion

In conclusion, sheet extrusion and film extrusion are two key plastic manufacturing processes that offer several advantages and disadvantages. Although the processes share some similarities, there are key differences between them. By understanding these differences, manufacturers can choose the best process for their specific application. As always, it is important to work with experienced plastic manufacturers who can help guide you in making the right choice to meet your goals.