Sheet Extrusion vs Thermoforming: A Comprehensive Comparison

Sheet Extrusion vs Thermoforming: A Comprehensive Comparison

Among various plastic manufacturing processes, sheet extrusion and thermoforming are two popular methods utilized to create plastic products. While both methods are capable of producing high-quality plastic products, each has its own advantages and disadvantages. In this article, we will compare and contrast sheet extrusion and thermoforming to help you make an informed decision when choosing one that fits your specific needs.

What is Sheet Extrusion?

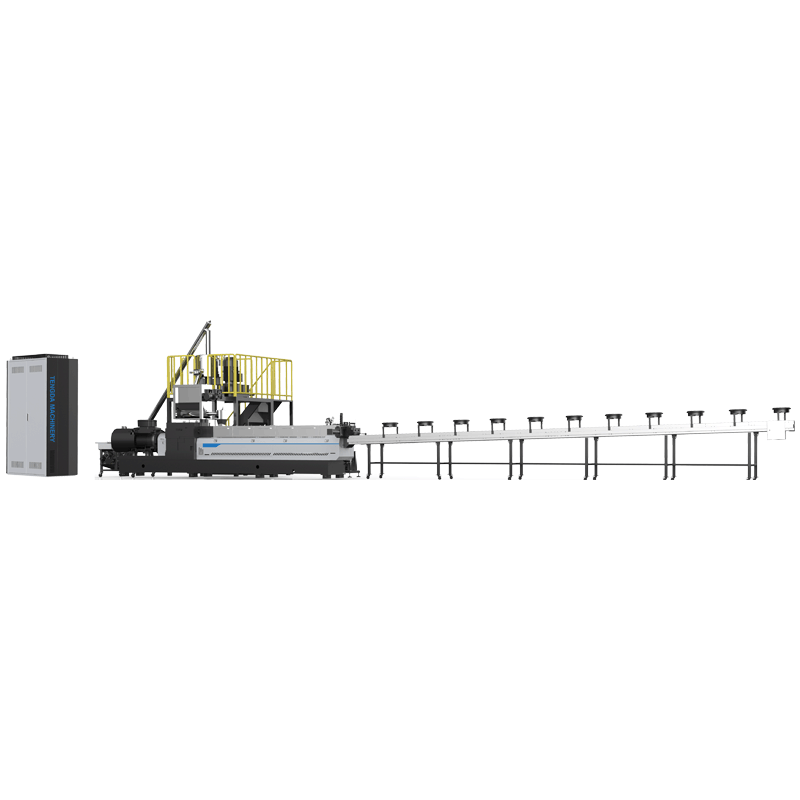

Sheet extrusion, also known as cast extrusion, is a plastic manufacturing process that involves extruding a molten plastic material through a die to form a flat sheet. This is a continuous process where the plastic material is fed into a hopper, melted, and then fed through the die to create a long sheet which is cooled down as it's taken up by a pulling system.

What is Thermoforming?

Thermoforming, also known as vacuum forming, is a plastic manufacturing process that involves heating a plastic sheet until it is pliable and then forming it into a desired shape using a molding tool, vacuum, or press. Thermoforming is a versatile process that can be used to create a variety of products, including food packaging, toys, and automotive parts.

Comparison

Now that we understand what sheet extrusion and thermoforming are, let's compare and contrast the two processes.

Material Selection

Sheet extrusion is typically used for manufacturing products that require consistent thickness and clarity, such as food packaging or plastic sheets used in construction. Because sheet extrusion produces consistent thickness, it's not suitable for creating products that require varying thickness.

Thermoforming, on the other hand, can be used to create products with varying thickness. This process is often used to create products such as car parts, toys, and trays. Thermoforming also allows for more flexibility in material selection, as it can be used with a wider range of materials than sheet extrusion.

Cost

Sheet extrusion is generally considered a cost-effective process, as it's a continuous process that can produce large volumes of products at a relatively low cost. However, it's not suitable for creating products that require a unique shape or design.

Thermoforming, on the other hand, can be more expensive due to the need for custom molds or tools. This is because thermoforming can be used to create products with unique shapes and designs. However, it's still a cost-effective process due to its versatility and ability to produce large volumes of products.

Production Time

Sheet extrusion is a continuous process that can produce large volumes of products quickly. However, it's not suitable for creating products that require a unique shape or design.

Thermoforming, on the other hand, can take longer to produce products due to the need for custom molds or tools. However, it's still a relatively fast process that can produce large volumes of products.

Quality

Sheet extrusion produces products with consistent thickness and clarity, making it ideal for creating products such as food packaging and construction materials. However, it's not suitable for creating products with varying thickness.

Thermoforming produces products with varying thickness, making it ideal for creating products such as trays and car parts. However, the quality of the product can vary depending on the quality of the mold or tool used in the process.

Environmental Impact

Sheet extrusion is generally considered to have a lower environmental impact than thermoforming. This is due to the fact that it uses less energy and produces less waste than thermoforming. However, it's still important to consider the environmental impact of the materials used in the manufacturing process.

Thermoforming can produce more waste than sheet extrusion due to the need for custom molds or tools. However, it can still be an environmentally friendly process if using recycled materials.

Conclusion

Both sheet extrusion and thermoforming are valuable methods for manufacturing plastic products, each with its own advantages and disadvantages. Factors such as material selection, cost, production time, quality, and environmental impact should all be considered when choosing between the two methods. We hope this comparison has helped you make an informed decision about which process is best suited for your specific needs.