Single Screw Extruders: Cost-Effective Solution for Small-Scale Production

Single Screw Extruders: Cost-Effective Solution for Small-Scale Production

Single screw extruders have been around for over a century and are the oldest known type of extruders in the industry. Over the years, they have continued to evolve, and today they are widely used in many different industries, including the food, pharmaceuticals, and plastics industries.

Single screw extruders are used for the production of a wide range of products, including plastic pipes, films, fibers, and profiles. They are also used in food and pharmaceutical applications for the extrusion of dough, gels, creams, and pastes. Single screw extruders are often chosen over twin-screw extruders in small-scale production due to their cost-effectiveness and ability to produce high-quality products.

In this article, we will explore the benefits of using single screw extruders in small-scale production and dive into how they work.

How Single Screw Extruders Work

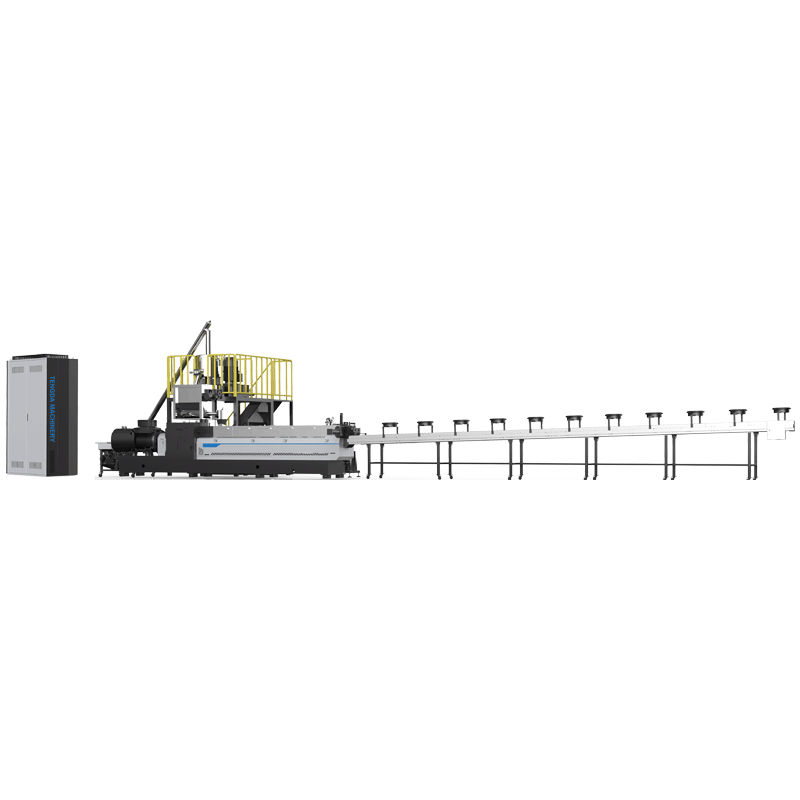

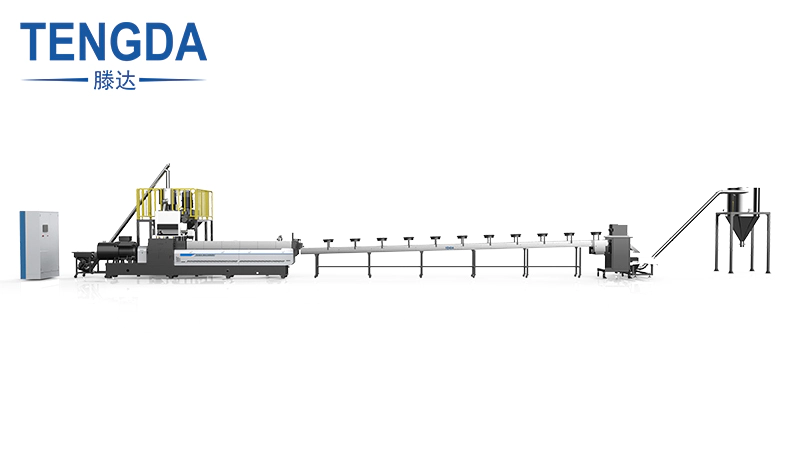

Single screw extruders are relatively simple machines that consist of a hopper, barrel, screw, and die. Raw material is fed into the hopper, and the screw rotates inside the barrel, pushing the material forward through the extrusion die. The die shapes the material to the desired form as it exits the machine.

The screw is the most critical component of the extruder because it is responsible for melting the raw material and pushing it through the die. It consists of a helical thread that wraps around a central shaft. As the screw rotates, the thread engages with the material in the barrel and moves it forward.

There are several different types of screws, each designed for specific applications. Conventional screws are used for the production of solid materials such as films, pipes, and profiles. Barrier screws are used to control material flow and are often used for the production of difficult-to-process materials. Mixing screws are used to mix different materials and additives and are commonly used in the plastics industry.

Benefits of Single Screw Extruders

Cost-Effective

Single screw extruders are a cost-effective solution for small-scale production because they are relatively simple machines that require less maintenance than twin-screw extruders. They are also typically less expensive to purchase and operate, making them an attractive option for small businesses.

Flexibility

Single screw extruders are flexible machines that can be easily modified to accommodate different materials and products. They can be used for the production of a wide range of products, including plastic pipes, films, fibers, and profiles. They are also used in food and pharmaceutical applications for the extrusion of dough, gels, creams, and pastes.

High-Quality Products

Single screw extruders are capable of producing high-quality products with consistent properties. This is because the screw design can be tailored to the specific requirements of the product, ensuring that the material is properly melted and mixed before it exits the die.

Easy to Operate

Single screw extruders are easy to operate and require minimal training. Operators can quickly learn how to operate the machine, set the parameters, and produce high-quality products. This makes them an attractive option for small businesses that may not have extensive experience in extrusion.

Limitations of Single Screw Extruders

Low Processing Speeds

Single screw extruders are not as fast as twin-screw extruders, and they have limitations in terms of processing speed. This means that they may not be suitable for large-scale production of some products.

Less Efficient Mixing

Single screw extruders are less efficient at mixing than twin-screw extruders. This means that they may not be suitable for the production of some products that require thorough mixing.

Limited Cooling Options

Single screw extruders have limited cooling options because the material is pushed through the die at a constant rate. This can be a limitation when working with materials that require precise cooling to achieve the desired properties.

Conclusion

Single screw extruders are a cost-effective solution for small-scale production because they are relatively simple machines that require less maintenance than twin-screw extruders. They are flexible machines that can be easily modified to accommodate different materials and products. They are also capable of producing high-quality products with consistent properties and are easy to operate, making them an attractive option for small businesses. While they have limitations in terms of processing speed, mixing efficiency, and cooling options, these limitations may not be significant for small-scale production of most products.

is a modern Application widely used in extruder machine manufacturers industry. It also enhances the quality plastic extruder machine manufacturers value of the products.

No, this isn't a wonder product and it won't be likely to change your life but it will give your extruder machine manufacturers a kick and bring the extraordinary to the every day. give it a shot at TENGDA Extruder Machine Manufacturers.

Obviously, financial return is important in manufacturing Application, but I think that's not enough. I think many customers want to support something they really believe in.

Armed with professional team and advanced equipment, Nanjing Tengda Machinery Co., Ltd. is specialized in offering high quality in various designs. Visit us at TENGDA Extruder Machine Manufacturers to find your desired .

We are proud to be a part of helping you to make healthy choices to last a lifetime. Check out our website to see all plastic extruder machine manufacturers Application products we offer at TENGDA Extruder Machine Manufacturers. If you want to start that road to be better, contact us today!