Solve 3 common problems of plastic granulator

How to get rid of the insufficient extrusion of the plastic granulator and insufficient product injection are often due to the fact that the raw material has dried before filling the die, and of course there are various other reasons. Let me introduce it to us. For temperature reasons, reduce the temperature of the barrel and nozzle, check the millivolt meter, thermal resistance, resistor electric heating coil or far-infrared heating device and heating system, increase the mold temperature, and check the mold temperature control device.

Reasons for molding: the flow channel of the plastic granulator is too small, the glue inlet is too small, the nozzle hole is too small, the location of the glue inlet is unscientific, the number of glue inlets is not enough, the cold material hole is too small, the exhaust pipe is not enough, the mold is produced The injection cycle time for is abnormal.

Reasons for machinery and equipment, silo termination of material, partial or complete blockage of silo diameter reduction, insufficient feeding volume, abnormal operation of the automatic feeding control system, melting volume size of the injection press, and abnormal injection cycle time caused by equipment.

Extrusion standard reasons, the injection pressure of the plastic granulator is too low, the injection pressure damages a lot during the extrusion cycle time, the injection time is too short, the rated power of the injection motor is too short, the injection speed is very slow, the mold The material flow in the core is interrupted, the mold filling speed is different, and the injection cycle time caused by the actual operation standard is abnormal.

Solve 3 common problems of plastic granulator

Some people ask that the feeding of the plastic granulator head is blocked or blocked, let's study its cause and solution. First of all, we need to understand the reasons why the feeding of the granulator head is blocked or short-circuited:

1. Whether there are dirty things that are not easy to melt.

2. A certain section of the electric heater does not work, and the material is not melted well.

3. The operating temperature setting is slightly lower, or the molecular weight of the plastic is spread widely and unstable.

Only by knowing the cause of the blockage or short circuit of the feed of the plastic granulator can the solution be carried out:

1. Check the electric heater and replace it if necessary.

2. Clean and check the extrusion device and machine head.

3. Check the set temperature of each section, and discuss with the production technician if necessary to increase the temperature preset value.

☆Why does the server of the plastic granulator not turn over?

The reason for this common failure is that the server of the plastic granulator does not turn over or shuts down for a moment. Generally, the switching power supply of the main power supply is not connected properly, or the heating time is not enough, or it is in one of the The electric heater does not work, resulting in excessive torque and causing the electric motor to overweight.

The correct way to deal with this common failure of the plastic granulator:

1. Check whether the server power supply circuit is connected, and connect the switching power supply

2. Check the temperature display status of each section and determine the heating time

3. Check whether each electric heater is damaged or has poor contact, and remove

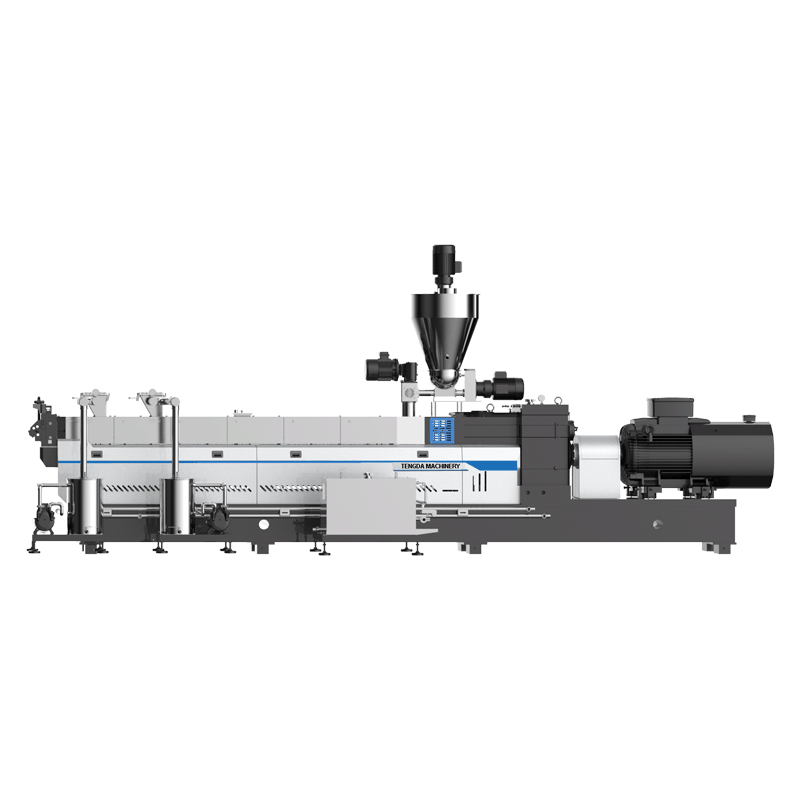

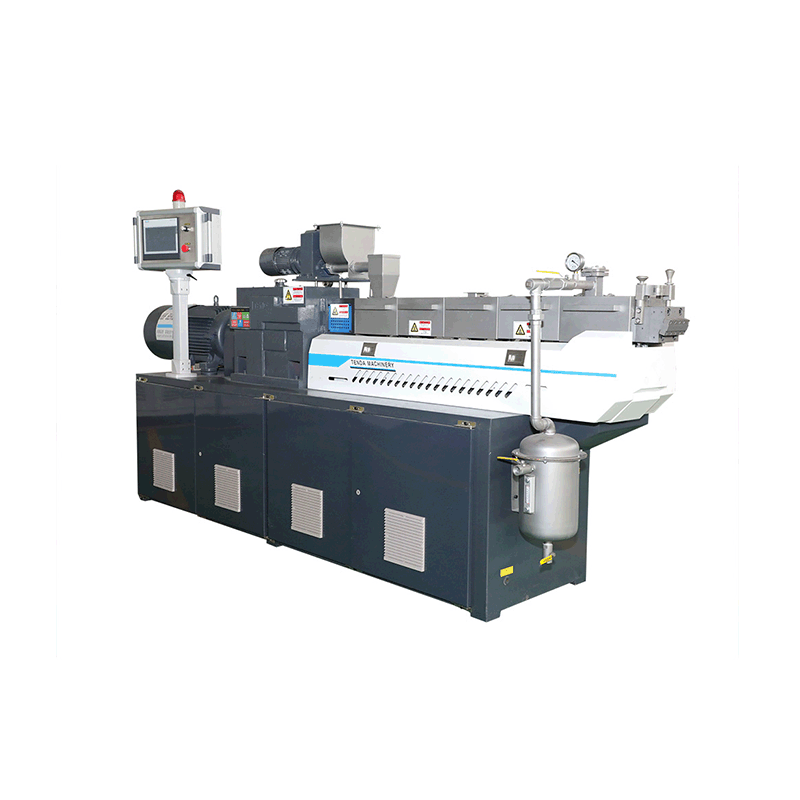

Nanjing Tengda Machinery Co., Ltd. is recognized as one of the leading manufacturer of in China.Trust in us and make Nanjing Tengda Machinery Co., Ltd. your Application supplier. Our products will bring more economic value to you.

We believe our capacity can give you an impressive experience by using Application.

As consumers get more and better information regarding how to compare various products and companies, it is critical to compete on the price and value of Application.