Some operating precautions for plastic extruders

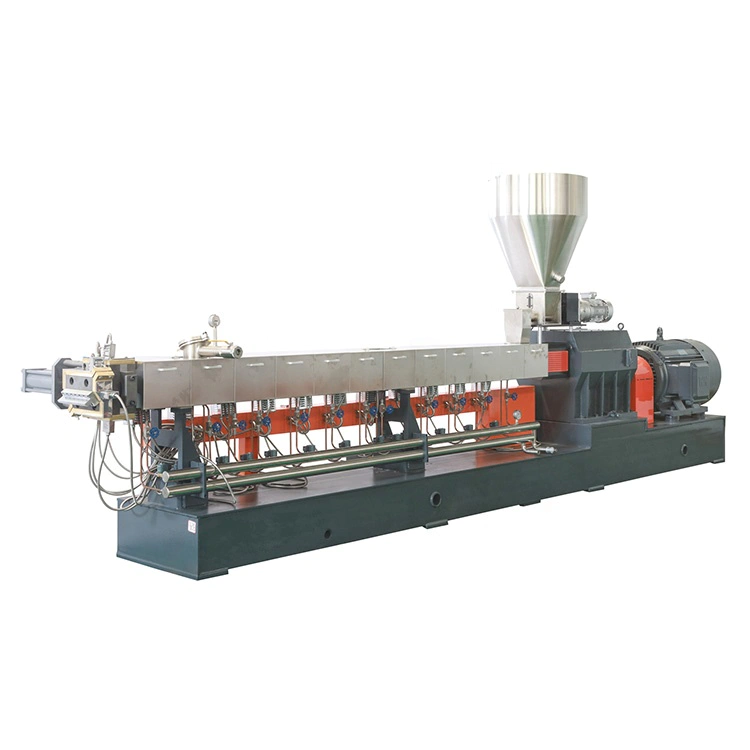

In the process of operating Xirun extruder, the operation process must be standardized, which can not only improve work efficiency, but also prolong the service life of the equipment. Below, let's take a detailed look at some precautions for operating the extruder equipment, hoping to be helpful to everyone.

1. The plastic extruder should use hydraulic oil with cleanliness, viscosity and other indicators that meet the requirements, and provide enough meteoric cooling water for the oil cooler according to regulations, so as to avoid hydraulic components and pipelines from being blocked due to oil pollution or high temperature , Obliteration of oil and other damage phenomena. Do not use low-quality recycled materials with metal impurities or sediment. Do not place metal objects that may fall in near the feed inlet to prevent the addition of green rods, wear between machines, or jamming and damage. When the material temperature does not reach the set temperature and the holding time does not change, it is not allowed to start the machine and run the rod.

2. The plastic extruder should run forward to avoid reverse. Do not run on an empty stomach, it must be run with hot engine and feed, so as to avoid the phenomenon of sticking bars. It is strictly forbidden to enter iron and other miscellaneous objects into the feed port and vent hole of the extruder, so as to avoid accidents and affect production.

3. After the material is mixed by the internal mixer, it is plasticized and becomes a lump. Since the above materials contain elastomers, they are highly viscous after being plasticized, and a small part of each batch of materials will stick to the mixing chamber more or less. Such residual materials will be overheated and decomposed, and even cause the whole roll of materials to become waste; In addition, the material plasticized by the mixer plastic extruder is bulky and elastic, so it is difficult to smoothly enter the next machine for extrusion, resulting in difficult operation.

Recently, TENGDA Machinery reminded everyone to operate the equipment strictly in accordance with the operating procedures of the plastic extruder, and not to perform illegal operations at non-operating stations. To ensure the reliability of the safety device, the safety protection measures of the machine must not be destroyed in pursuit of efficiency.

plastic extruder machine manufacturers are required in the manufacture of almost every product and extruder machine manufacturers Application is one of the most common machines.

Check out TENGDA Extruder Machine Manufacturers for optimal quality products, and get your Application problem fixed. Send us an enquiry or make a call if you are interested.

Using high-quality materials to produce Application is one of the most important part during manufacturing.

The best way to determine the ideal strategy of Application is to continually test and refine your selling and marketing tactics.