Steel Extruder vs Brass Extruder: Which Material Offers Better Strength?

Steel Extruder vs Brass Extruder: Which Material Offers Better Strength?

The materials used to construct 3D printer extruders are essential to the quality of the final product. Two popular materials for extruders are steel and brass. Steel extruders have been gaining popularity over brass extruders, but the question remains: which material offers better strength? In this article, we will compare and contrast the properties of both materials to determine which is best for your 3D printing needs.

Introduction to 3D Printer Extruders

Before we delve into the comparison of brass and steel extruders, let's take a moment to understand the role that an extruder plays in 3D printing.

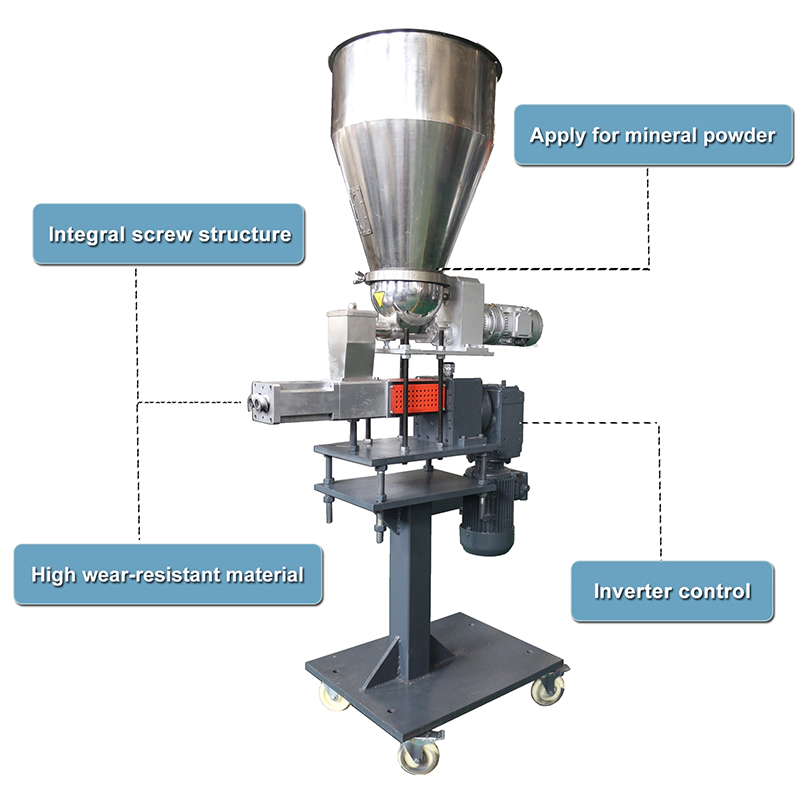

An extruder is the part of a 3D printer that deposits molten plastic or other materials onto the printing surface, layer by layer. The extruder heats up the material and then drives it through a nozzle to create the necessary shapes in the 3D model. The strength and quality of the extruder greatly influence the precision and accuracy of the final print.

Properties of Steel Extruders

Steel is a popular material for 3D printing extruders due to its excellent durability and strength. Steel extruders can handle high loads and resist wear and tear from continuous use. The high strength of steel extruders also allows for the use of higher pressure to extrude materials.

Steel extruders come in different types, such as hardened steel and stainless steel. The use of hardened steel in extruders provides superior resistance to wear and tear and high temperatures. Stainless steel extruders, on the other hand, are popular due to their resistance to corrosion and their high strength-to-weight ratio.

Properties of Brass Extruders

Brass is another popular material for 3D printing extruders, but it is generally less durable than steel. However, brass extruders do have some benefits.

Brass has excellent thermal conductivity, which means it can transfer heat efficiently, making it a preferred material for hot ends in 3D printers. Brass extruders can also provide excellent surface finish quality to printed parts.

In terms of strength, brass is weaker than steel. Brass extruders are generally used for smaller and less demanding prints that do not require the use of high temperature or pressure.

Comparison of Steel and Brass Extruders

Now that we have defined the properties of steel and brass extruders, let us compare them in more detail.

Strength

Steel is undoubtedly stronger than brass, which means that steel extruders can handle more demanding and complex prints. The high strength of steel allows for the extrusion of a broader range of materials, including abrasive filaments such as carbon fiber-filled filaments.

Brass extruders, on the other hand, are better suited for smaller prints that do not require high loads or pressure.

Durability

The durability of an extruder is crucial to the precision and quality of the final print. Steel extruders have a longer lifespan than brass extruders due to their resistance to wear and tear. Steel extruders can withstand higher temperatures and pressures, which make them more suited for continuous printing or printing large models.

Brass extruders, on the other hand, can wear down with prolonged use, leading to clogs, filament jams, and even breakage.

Cost

The cost of steel and brass extruders varies depending on the type and quality of the material used. Steel extruders are generally more expensive than brass extruders due to their superior strength and durability.

However, when used in demanding prints, a steel extruder can save you money in the long run due to its long lifespan and lower maintenance costs.

Thermal Conductivity

The thermal conductivity of an extruder determines how efficiently heat is transferred to the filament, which is essential for successful 3D printing.

Brass extruders are known for their excellent thermal conductivity, which makes them the preferred material for hot ends. A good hot end is essential to the quality of the final print, and brass extruders can help ensure smooth and even melting of the filament, providing excellent print quality.

Steel extruders, on the other hand, are not as efficient in transferring heat as brass extruders. However, steel extruders can handle high temperatures without deforming, which means that they are better suited for high-temperature printing.

Conclusion

In summary, selecting the right 3D printing extruder material depends on the specific needs of your prints. Steel extruders are superior to brass extruders in terms of strength and durability, making them ideal for demanding and complex prints, especially those that require high temperatures and pressure.

Brass extruders are better suited for smaller prints since they wear down faster than steel extruders. They are, however, excellent at thermal conductivity, which makes them perfect for hot ends.

When deciding between steel and brass extruders, it is essential to take into account the needs of your final prints and choose the material that best meets those requirements.