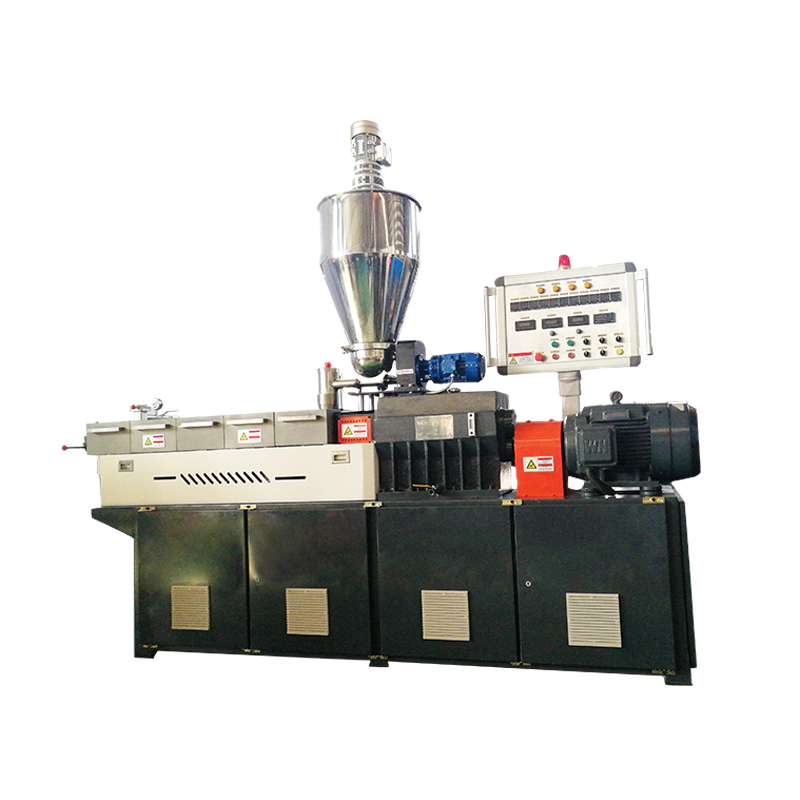

Structural analysis of co-rotating parallel twin-screw extruder

1. Intuitively understand the wear of the wearing parts of the co-rotating parallel twin-screw extruder. Because it is easy to open, the wear degree of the threaded components and the inner barrel of the barrel can be found at any time, so as to carry out effective maintenance or replacement.

2. It has a wide range of applications and can be applied to the processing of various materials.

3. Reduce the production cost. When changing the color of the twin-screw extruder, it only takes a few minutes to quickly open the barrel and perform manual cleaning, so that no or less cleaning material can be used, which saves costs.

4. High torque and high speed. At present, the development trend of twin-screw extruders in the world is to develop in the direction of high torque, high speed and low energy consumption. The effect of high speed is high productivity.

5. High output, high quality and high efficiency, with other advantages of ordinary twin-screw extruder, it can achieve high output, high quality and high efficiency.

6. Improve labor efficiency. During equipment maintenance, ordinary twin-screw extruders often have to remove the heating and cooling systems first, and then extract the screw as a whole. The split-type twin-screw does not need, just loosen a few bolts, turn the worm gear box handle device to lift the upper half of the barrel to open the entire barrel, and then carry out maintenance. This not only shortens the maintenance time, but also reduces the labor intensity.

Screen changing and dicing methods, electrical instrument control mode, etc. can be optimally configured and adjusted according to material system and process requirements, and a unified consideration of multi-function, multi-purpose and specific exclusivity can be implemented. It has the characteristics of high productivity and low specific energy consumption. The screw and barrel of the twin-screw extruder granulator are designed on the principle of building blocks, the shape of the thread, the structure of the barrel, the ratio of length to diameter, the number of feeding and exhaust positions.

Nanjing Tengda Machinery Co., Ltd. is specialized in sourcing plastic extruder machine manufacturers Application through its unparalleled worldwide network of supply. Go to TENGDA Extruder Machine Manufacturers, you will surely find your ideal at the most favorable price.

Nanjing Tengda Machinery Co., Ltd. intends to make enough profit to generate a fair return for our investors and to finance continued growth and development in Application.

The extruder machine manufacturers Application has significantly numerous benefits over other plastic extruder machine manufacturers systems, which makes it first choice for extruder machine manufacturers.