Structural characteristics of co-rotating parallel twin-screw extruder

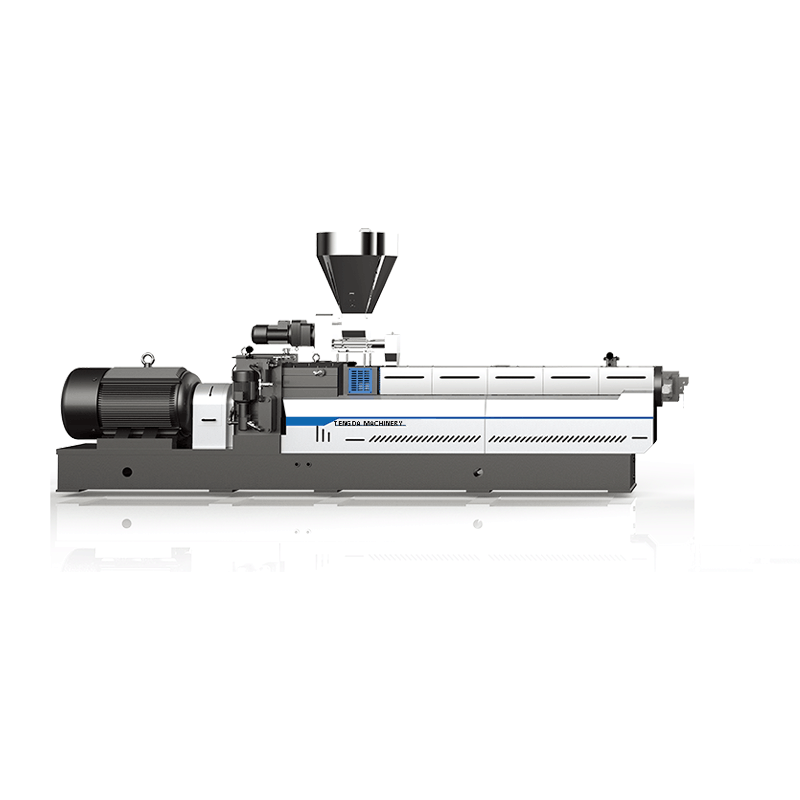

The screw and barrel of the co-rotating parallel twin-screw extruder host adopt advanced 'building block' design. The screw is composed of various forms of screw blocks set on the mandrel. The different blocks can be adjusted, so as to flexibly combine the ideal threaded element structure according to the process requirements such as material varieties, and realize various technological processes such as material transportation, plasticization, thinning, shearing, exhausting, pressure building and extrusion. , so as to better solve the so-called contradiction between the so-called universality and specificity of the screw that is generally difficult to take into account, and achieve the purpose of one machine with multiple functions and one machine with multiple functions.

The advanced control system of the co-rotating parallel twin-screw extruder. The extruder is equipped with an advanced and beautiful control system, and most of its control components are imported components with good quality and high sensitivity. The operating parameters of the host such as current, voltage, temperature, torque, etc. are very intuitive, so the operation is very convenient, and the requirements for the operator are not high. Accurate measurement and reasonable feeding method are the key to strictly implement the formula and ensure product quality. According to the performance of the material and the needs of users, we are equipped with a variety of feeding methods, such as volume measurement, dynamic weight loss measurement, etc., to meet the needs of customers. different product needs.

The twin-screw of the co-rotating parallel twin-screw extruder is of high-speed co-directional meshing type, which can produce very strong and complex material transfer and exchange, split-flow blending and shearing kneading in various threads and mixing elements. These functions can be fully adjusted and controlled by changing the screw configuration and operating process conditions to meet the requirements of various processes. The system is equipped with several dicing methods such as wire drawing water cooling, hot water cooling, hot air cooling, etc. It can be configured according to different materials and user requirements.

Professional plastic extruder machine manufacturers also understand that when you're working with extruder machine manufacturers product, it's important to understand that quality of Application always matters.

We humbly ask you to use Application and we guarantee that you would be in a great delight with using the product.

Application allows users to use in innovative ways that fit their individual needs, while at the same time providing cost-effective, reliable and user-friendly products.