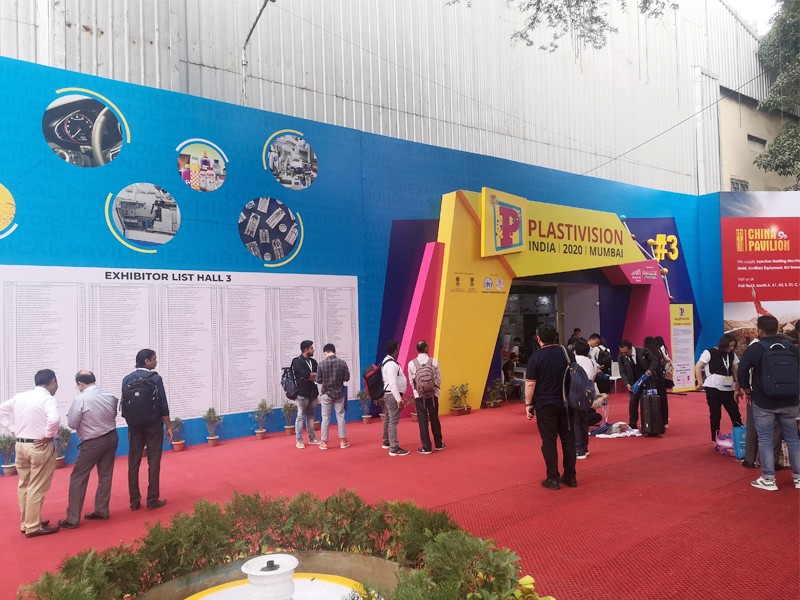

2020 India International Plastic Industry Exhibition

The India International Plastic Industry Exhibition was held at The Bombay Convention & Exhibition Centre, January 16,2020

The Bombay Convention & Exhibition Centre (BCEC) is the largest permanent exhibition Center in India’s private sector. Since it was built in 1991, the BCEC has hosted several prestigious international Trade fairs and exhibitions. The Center is ideally situated along the Western Express Highway in Goregaon and within a 10 minute drive from national and international airports and 30 minutes from the heart of the city. The vicinity offers a number of convenient hotels of all categories for exhibitors and visitors.

India's economy is developing rapidly, especially in recent years, its GDP growth rate has reached an average of more than 7%, which has surpassed member states such as China.India is one of the fastest growing plastic markets in the world and has become the third largest plastic producer; high speed, complex processing machinery and auxiliary equipment, mold demand is unstoppable.Low import tariffs provide overseas plastic manufacturers with more opportunities to trade and cooperate with local plastic manufacturers. Many professional audiences in neighboring countries, such as Bangladesh, Sri Lanka, some countries in the Middle East and Africa, also came to the exhibition site to add more trade opportunities to the exhibitors.

And this time we brought out the equipment for the exhibition is SE series screw extruder pelletizing system.

The SE series single screw extruder pelletizing system could best use in ABS、PC、POM、PP、PE、PC/ABS plastic raw materials dyeing and engineering plastics recycling Granulation.

High-precision gearbox, high loading capacity, steady driving, low noise;Newly barrel and screw design to ensure good melt uniformity, low melt temperature and high production;The barrel and screw are subject to the nitrogen treatment, with high anti-wear and anti-corrosion performance; Super mute blowing fan cooling barrel, free of maintenance operation; Imported temperature-controlled meter, PID temperature control, and temperature control is more stable and accurate;The die head design comprises manual revolving type or hydraulic type, and it is easy and time-saving to change the screen.