TENGDA will be invited to attend the CHINAPLAS in 2023

Date: April 17 - April 20

The 35th CHINAPLAS originally scheduled from 25-28 April 2022 at National Exhibition and Convention Center in Shanghai, will be postponed to 17-20 April 2023, and the show venue will be changed to Shenzhen World Exhibition and Convention Center in Shenzhen in 2023 in view of the latest COVID development in Shanghai. The CHINAPLAS has been successfully held nearly 4 decades, which give a push to promote the global rubber and plastics industry’s development. At that time, the global suppliers and buyers will catch the chance to facilitate business exchanges and cooperation.

China is a country with large plastics and rubber production and consumption in the world. Not only supplying higher quality and cost-effective goods for consumers but also give strong support in many land use all around the world, for instance deep drilling and deep water operations, nuclear energy uses, oceans and desert power farm construction, aviation&aerospace and polar expedition.

As members of them, TENGDA has been focused on high-end twin-screw extruders for over 10 years. Our company established the twin-screw technology R& D division jointly with the Automation Research Institute of China North Industries Group in 2013 so as to promote the research and development of high-end twin-screw extruders.TENGDA have injected high-precision technology into the production of extruder machine. TENGDA specializes in the research,development and manufacturing of plastic polymer compounding modification equipment with co-rating twin-screw extruders as the core,as well as related process and engineering fields.

TENGDA has been known for good reliability, winning the trust of new and old customers, and insisting on creating the greatest value to customers. TENGDA will take part in the CHINAPLAS in Shenzhen World Exhibition and Convention Center in 2023 and our company will show our star products.

1.TSH-Plus Series Co-rotating Twin-srew Compounding

Units technical characteristics:

(1)Capacity is increased by 10%-20%, while energy saving is increased by 5%-15%.

(2)The total cooling of the equipment only needs to be connected to the inlet and outlet water, which reduces the customer's installation cost.

(3)Beautiful appearance, simple maintenance. Without debugging, it can be quickly installed.

(4)Integrated design of vacuum and water tank.

(5)Overall reliability and quality stability of lead in China.

(6)No debugging, quick installing.

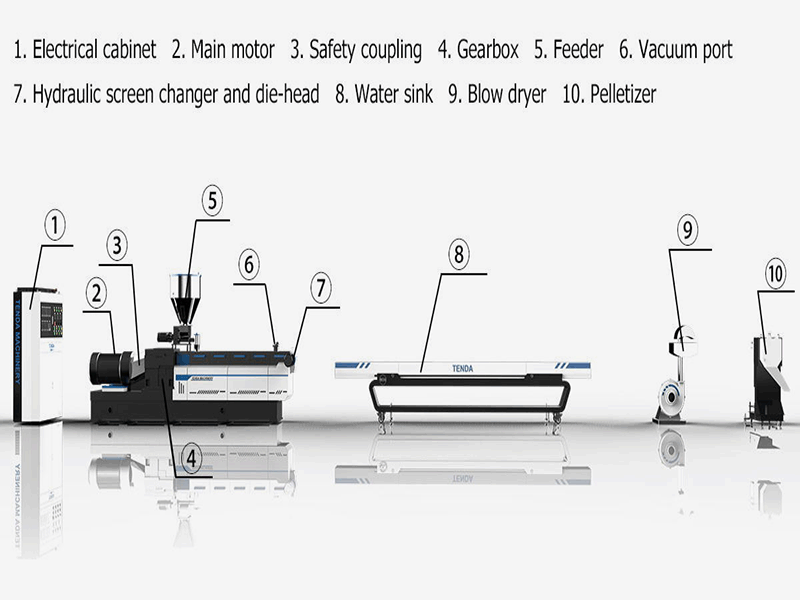

2.TDH Series Co-rotating Twin-screw Pelletizing units

Units technical characteristics:

(1)Imported high torque gear box and lubrication system, with high torque and high speed;

(2)It is equipped with high torque screw shafts, nickel based carbide barrels and high wear-resistant screw elements.

(3)Electrical control system is high-end touch screen system. All components are international well-known brand.

(4)The barrels, screw elements, gearbox of the main extruder are all produced by CNC milling machining center.

“Tengda Machinery” will create excellent quality twin-extruders machines, and if you are interested in any of our products or wanting to get more information about the twin-extruders machines of TENGDA,please don’t hesitate to contact us directly for more information. TENGDA will serve you wholeheartedly forever! If you need the invitation of this exhibition, you can also contact TENGDA, TENGDA will send it to you in time. We are looking forward to your joining in CHINAPLA 2023!