Understanding the Impact of Die Lip Flow in Extruded Products

Understanding the Impact of Die Lip Flow in Extruded Products

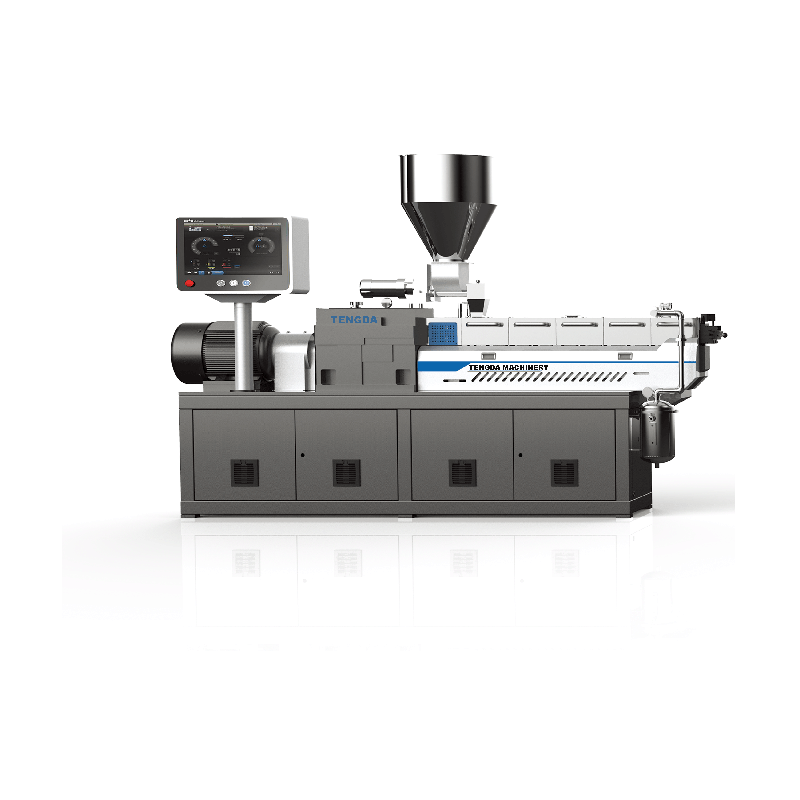

Plastic extrusion is an essential process used in many industries for the production of different products. The process involves the creation of a continuous profile by pushing melted plastic through a die. The rate at which the plastic emerges from the die is vital in determining the final product quality. One of the aspects that contribute to the quality of the extrusion products is the die lip flow. This article covers a detailed overview of the impact of die lip flow in extruded products.

Introduction to Die Lip Flow in Extrusion

The die lip flow refers to the movement of the plastic material within the die during the extrusion process. In most cases, the plastic emerges out of the die as a flat sheet or a film, cut to size when required. The die lip is responsible for the final shape and thickness of the extruded product.

Understanding the Die Lip Design

The design of the die lip significantly influences the flow of the plastic material. The die lip comprises of two primary components, including the sharp edge and the land. The sharp edge is responsible for shaping the plastic material while the land serves as a support. The design of the die lip is crucial because it determines the final shape and thickness of the extruded product.

Impact of Die Lip Flow

The die lip flow has an incredible impact on the final quality of the extruded products. One of the primary effects of the die lip flow is the creation of uniformity in the thickness of the product. If the quantity of plastic displaced by the die lip is consistent, the final product will have uniform thickness throughout its length. Similarly, if the die lip is not uniform, the product thickness will vary, which can affect the final product quality.

Reducing the Impact of Die Lip Flow

Die lip design plays a significant role in reducing the impact of die lip flow. For example, a sharp edge will provide a better cut, and a uniform land will provide a better support. However, other factors can also influence the impact of die lip flow, including the material properties and the process conditions. Understanding how these factors interact will help in designing a die lip that reduces the impact of die lip flow on the final product quality.

Conclusion

The die lip flow is an essential aspect of the extrusion process that can affect the final product quality. Understanding the die lip design and the impact of die lip flow is critical in producing high-quality extruded products. By designing a uniform die lip, the thickness of the extruded product can be precisely controlled, resulting in a consistent and high-quality product.