What are the advantages and disadvantages of the three-screw extruder?

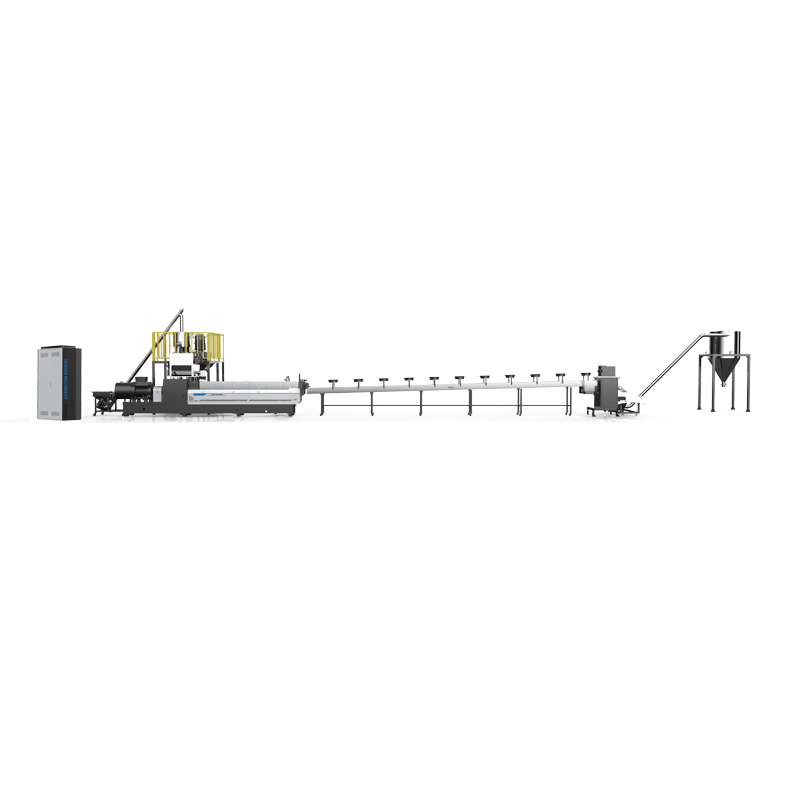

The three-screw extruder is a novel and unique extrusion machine, which has high shearing efficiency, good plasticizing effect, compacting function, good dispersion effect, high output, low energy consumption, good exhaust performance and the material is in the machine. Short residence time in the cylinder, not easy to be degraded and other performance characteristics, so does it have any disadvantages besides these advantages? Next, TENGDA Plastic Extruder Machine Manufacturers will briefly analyze the advantages and disadvantages of the three-screw extruder for everyone. Interested parties Partners may wish to take a look with TENGDA Plastic Extruder Machine Manufacturers!

Advantages of three-screw extruder:

1. High shearing efficiency and good plasticizing effect

A pair of screws has one point of engagement, while three screws have three points of engagement. That is to say, it is equivalent to three pairs of twin-screws, so the shearing efficiency is high and the material is easily plasticized. When testing the blue masterbatch with a pigment content of 15%, the screw was pulled out for inspection, and it was seen that the material had been plasticized in the middle of the full length of the screw, indicating that the plasticizing effect was good.

2. Good refining function and good dispersion effect

The three screws are inverted“Taste”The fonts are arranged to form a closed space in the central area. Every time the screw rotates once, the space through the central area of the same section changes from 7.5 square millimeters to 321 square millimeters, and the change is three times, that is, when the compression ratio is 43 times and the screw speed is 500 rpm, the change is 3 times.×30×500=45000 times, if the material stays in the machine for 20 seconds, the material will be strongly backlogged and kneaded for 15000 times in the machine.

Therefore, it is uniformly plasticized and dispersed. Therefore, this machine is an extruder with very good dispersion that integrates compaction and extrusion. Practice has proved that when producing carbon black masterbatch, the content of carbon black can reach 55%, the content of magnesium hydroxide in low-smoke, halogen-free and flame-retardant cable materials can reach 90%, and the addition of calcium carbonate in PP or PE masterbatch can reach more than 85%, and the effect is very good. .

3. High output and low energy consumption

Its output is twice that of twin-screw extruders with the same specifications and power. For the production of the same quantity of products, the cost of manpower and space required is doubled. And because of its short length-to-diameter ratio, the power of the main engine and the power of the heater are reduced to save energy.

4. Good exhaust performance

There is no material accumulation at the exhaust port of the machine, and there is no material leakage or blockage. The reason is that the material is almost all sucked into the honey refining area in the center of the screw. The mixing area is equivalent to a melt pump, so there will be no risk of leakage. material. So the machine can achieve a high degree of vacuum, which improves the quality of the product.

5. The material stays in the barrel for a short time and is not easy to be degraded

The length-to-diameter ratio of this machine is 22. The length-to-diameter ratio is equivalent to the twin-screw 66. However, the residence time of materials in the barrel can be shortened by one-third. Therefore, this machine is suitable for materials that are heat-sensitive and fear of degradation.

Disadvantages of three-screw extruder:

1. The material transportation of the three-screw extruder mainly depends on friction, which limits the feeding performance, and it is difficult to add powder, paste, glass fiber and inorganic fillers.

2. When the head pressure is high, the reverse flow will increase and the productivity will decrease.

3. The material of the three-screw extruder has little surface renewal effect in the exhaust area, so the exhaust effect is poor.

4. The three-screw extruder is not suitable for certain processes, such as polymer coloring, processing of thermosetting powder, etc.

Nanjing Tengda Machinery Co., Ltd. has an array of branches in domestic for servicing customers with high-quality products.

The guiding vision of Nanjing Tengda Machinery Co., Ltd. is 'Bringing the best to everyone we touch'. By 'The best', we mean the best products, the best people and the best ideas.

Even Application are being made fine with advanced equipment.