Nanjing

twin-screw extruder equipment is widely used in agriculture, industry, building materials production, machinery manufacturing, electronic processing and other fields. Twin-screw equipment has been involved in every field of our daily life and work. The main material for twin-screw equipment production It is a plastic product, and the production process is a plastic processing method of extrusion molding, so the technology and research and development of the twin-screw extruder equipment will be very meaningful. The following briefly introduces the relevant content of the twin-screw extruder equipment. Nanjing twin-screw extruder equipment is mainly used to produce and process plastic raw materials. It is not only suitable for processing high polymer plastic materials, but also extrusion molding and mixing processing of plastic raw materials. The use of this equipment can involve our daily food, building materials, product packaging, paper manufacturing, and ceramic processing fields. Twin-screw extruder equipment can improve product production and processing efficiency, shorten product production cycle, and reduce product production Cost, improve the rate of return of the product. Twin screw extruder equipment is mainly composed of screw, barrel, heating and cooling system, transmission system and control system. Among them, the screw and barrel are the main components of the twin-screw extruder. Whether the two can operate efficiently and normally is directly related to the production and processing quality and capacity of the product. The screw and barrel provide power support for the extruder equipment, so before daily production and processing, the screw and barrel must be overhauled and maintained to eliminate hidden power hazards, prepare equipment for production and processing, and ensure normal production and processing conduct. The heating and cooling system, transmission system and control system in Nanjing twin-screw extruder equipment are also indispensable and important parts of the extruder. The heating and cooling system can ensure the normal operation of the twin-screw extruder and the stable temperature during the production and processing of the extruder. The transmission system can provide operating power for the screw of the extruder to ensure stable operation and no large fluctuations in the speed. The control system is mainly composed of electrical equipment, instrumentation equipment and actuators. The above is the introduction about the relevant content of the twin-screw extruder equipment.

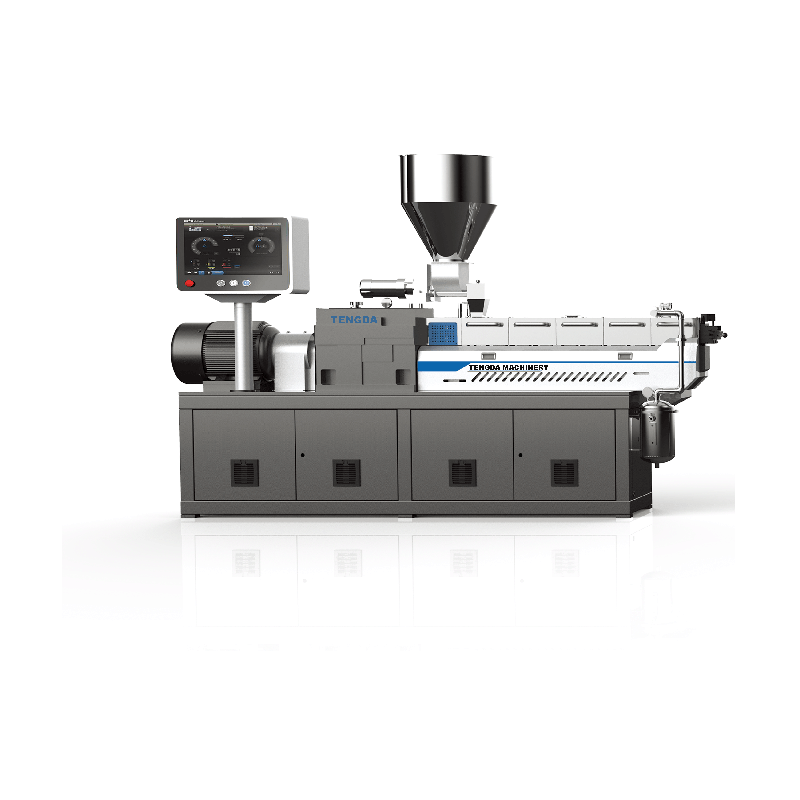

Nanjing Tengda Machinery Co., Ltd. is committed to fulfill the demands of our customers with using Application.

For more advice on tips, please visit our website TENGDA

Extruder Machine Manufacturers. Do not hesitate to contact us if you are interested.

You can get more information from TENGDA Extruder Machine Manufacturers for on sale. welcome to visit us and send your inquiry!