What are the application fields of twin-screw granulator? Its professionalism is reflected in these aspects!

Application fields of twin-screw granulator:

1. Agricultural chemistry

The twin-screw granulator embodies the high-quality performance and economic benefits of the twin-screw granulator in the mixing and granulation process of chemical fertilizer dry powder materials and slurry granulation process, and is especially suitable for compound fertilizers.

2. Metallurgy

Twin-screw granulator technology is widely used in raw material processing and refining and sorting of products and waste.

3. Refractory materials

The twin-screw granulator can be designed according to the performance characteristics of refractory materials and applied in various production lines.

4. Ceramics

The twin-screw granulator not only provides the ceramic industry with high-efficiency process technology, but also provides different processes for the development and production of new products and the improvement of product grades. Process technology is now regarded as the basis of standard process theory.

What are the professional aspects of the twin-screw granulator?

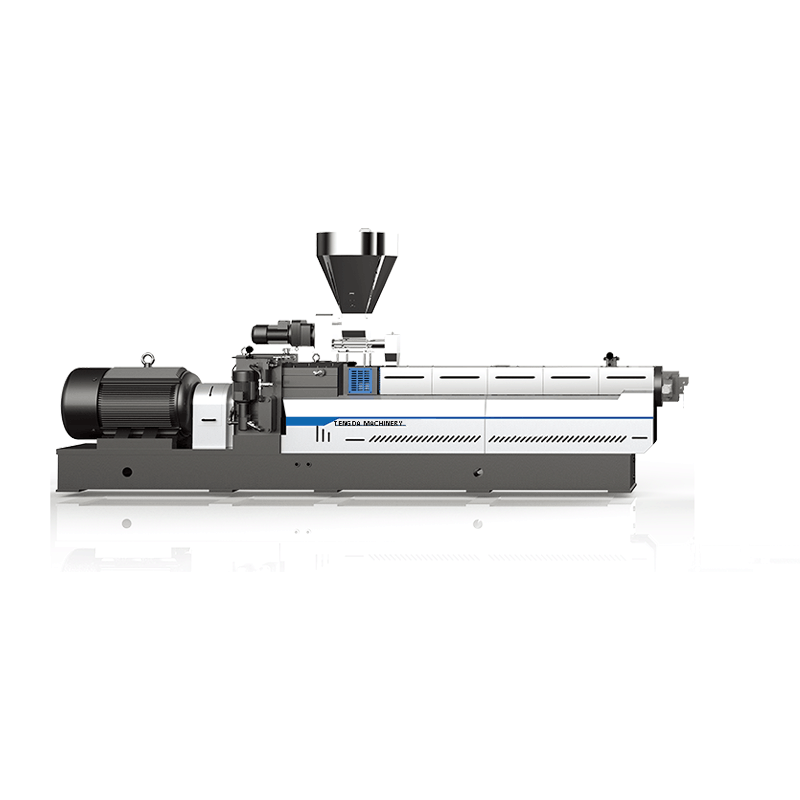

1. The twin-screw granulator is a device that integrates mixing and granulation. First of all, it has good mixing performance. It adopts the rotor structure design of multi-layer blade flying knife, which can quickly disperse various materials, and the stirred materials are uniform. High precision, the simultaneous reverse operation of the rotor and barrel can enhance the effect of intense movement, and has strong functionality.

2. The frequency conversion operation of the twin-screw granulator realizes the staggered mixing process, and the high-speed shearing of the blades makes the mixing efficiency faster, the energy utilization rate is high, and the cost is reduced.

3. The twin-screw granulator has a long service life: all vulnerable parts are designed with minimal wear, and high wear-resistant lining materials are installed on the wall and bottom of the cylinder. The mixing blades and scrapers are made of hard alloy patches or multi-layer pairs welding, so that it has a long service life.

After reading these introductions of TENGDA Plastic Extruder Machine Manufacturers, do you know more about twin-screw granulator? If you still encounter any problems during the operation, you can come to consult us!

Nanjing Tengda Machinery Co., Ltd. who is highly knowledgeable about manufacturing as well as selling and confident in our ability to create finest products as Application extruder machine manufacturers.

Nanjing Tengda Machinery Co., Ltd. supports these goals with a corporate philosophy of adhering to the highest ethical conduct in all its business dealings, treatment of its employees, and social and environmental policies.

Nanjing Tengda Machinery Co., Ltd. provides innovative technology and prompts our customers to know the development of our producing Application.

The unique connections between Applicationmanufacturing and customers happen when you find ways to relate on a more personal and engaging level that goes beyond a product.