What are the auxiliary equipment of twin screw extruder?

Nanjing Twin Screw Information: The twin screw extruder produced by the twin screw extruder manufacturer is composed of a screw and a barrel. Among them, the barrel is a split type, and the screw and the liner in the barrel can be combined at will. In addition, there are some auxiliary equipment, such as: preheating device, cooling device, straightening device, etc.

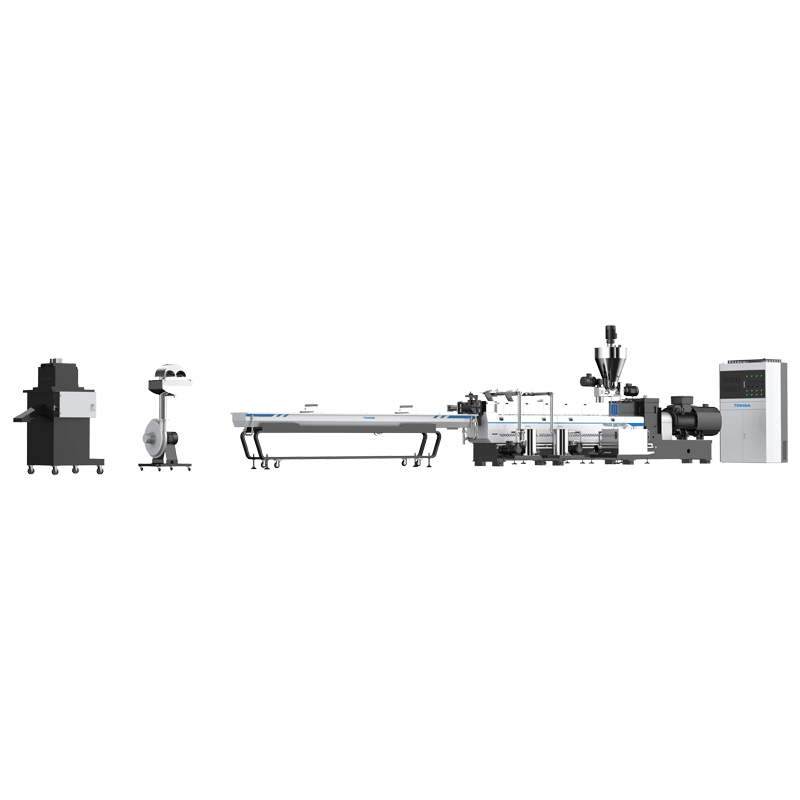

Today, the twin-screw extruder manufacturer-Tengda Machinery will give you a detailed introduction to the auxiliary equipment of the twin-screw extruder.

1. Preheating device

The preheating of the twin screw extruder cable core is very important for sheath extrusion and insulation extrusion. . For sheath extrusion, its function is to dry the cable core to prevent moisture from entering the sheath to form pores; it can also prevent the residual internal pressure of the extruded plastic due to quenching; for the insulation layer, especially the thin layer insulation, it is Preheating the core can completely remove the oil and moisture on the surface; in the process of extruding plastics, preheating can remove the cold wire from entering the high temperature die, forming a temperature difference, which can stabilize the extrusion volume and ensure the quality of the extrusion. This is also a twin screw extrusion process. The reason why the manufacturer must use the preheating device.

2. Cooling device

After leaving the machine head, the molded plastic extruded layer should be cooled and shaped immediately, otherwise it will be deformed, which requires a cooling device . The cooling method is mainly water cooling, which is divided into rapid cooling and slow cooling. Rapid cooling is direct cooling, which is conducive to shaping; slow cooling is to reduce the internal stress of the product.

3. Straightening device

In the sheath extrusion, the scratch on the sheath surface is caused by the bending of the cable core. The bending will cause the insulation eccentricity, which will cause the product plastic Squeeze out waste. Therefore, the straightening device in various extrusion units is also indispensable. The main types of straightening devices are roller type, winch type, pulley type and drum type.

What are the auxiliary equipment of the twin screw extruder? Through the above points, everyone has a certain understanding. It can be seen that the auxiliary equipment of the twin-screw extruder plays a very important role in the production process of the twin-screw extruder manufacturer. It is the indispensable equipment. The function guarantees the quality of the product.

Nanjing Tengda Machinery Manufacturing Co., Ltd., a leader in the development and manufacturing of twin-screw extruders and twin-screw pelletizers, specializes in the research and development of various plastic processing and extrusion equipment And manufacturing, until turnkey project. The products cover Nanjing twin-screw, twin-screw extruder, twin-screw extruder manufacturers, twin-screw granulator, plastic extruder, plastic pellet machine and plastic granulator, etc.

The use and installation of Application is compared with most other systems for managing the extruder machine manufacturers effectively and no doubt Application have won the race so many times.

Nanjing Tengda Machinery Co., Ltd.’s goal is to provide the customer with an enjoyable, honest service by satisfying individual customers practical transportation needs with a quality product.

Nanjing Tengda Machinery Co., Ltd. can promise that Application is one of the best products sold in the worldwide market at present.