What are the causes and solutions of poor plasticization of twin-screw extruder equipment?

In the process of frequently using the plastic extruder, we will encounter some phenomena that lead to poor plasticization, so what causes the poor plasticization? And how to solve this problem? Well, let's start Entering the topic, I hope my article can help you. I will list the specific situation and solutions as follows for you to refer to.

The manifestation of bad plasticization of twin-screw extruder equipment:

The surface of the plastic outer layer has the phenomenon of toad skin; the temperature control, the actual measurement temperature is low, and the temperature indicated by the instrument pointer is low; the plastic surface is black with tiny cracks and small particles that have not been plasticized; the plastic glue is not well sewn , there will be a clear trace.

Common reasons for poor plasticization of twin-screw extruder equipment:

Temperature control is too low or inappropriate;

There are resin particles that are difficult to plasticize in the plastic;

The operation method is improper, the screw and traction speed are too fast, and the plastic is not fully plasticized;

When the twin-screw extruder equipment is granulated, the plastic is not mixed uniformly or the plastic itself has quality problems.

Common troubleshooting methods for poor plasticization of twin-screw extruder equipment:

Control the temperature according to the process regulations, and adjust the temperature appropriately if the temperature is found to be low;

It is necessary to properly reduce the speed of the screw and traction, so as to increase the heating and plasticizing time of the plastic, so as to improve the plasticizing effect of the plastic;

Use the screw cooling water to enhance the plasticization and tightness of the plastic;

When choosing a mold, the mold sleeve should be appropriately smaller to increase the pressure of the glue outlet.

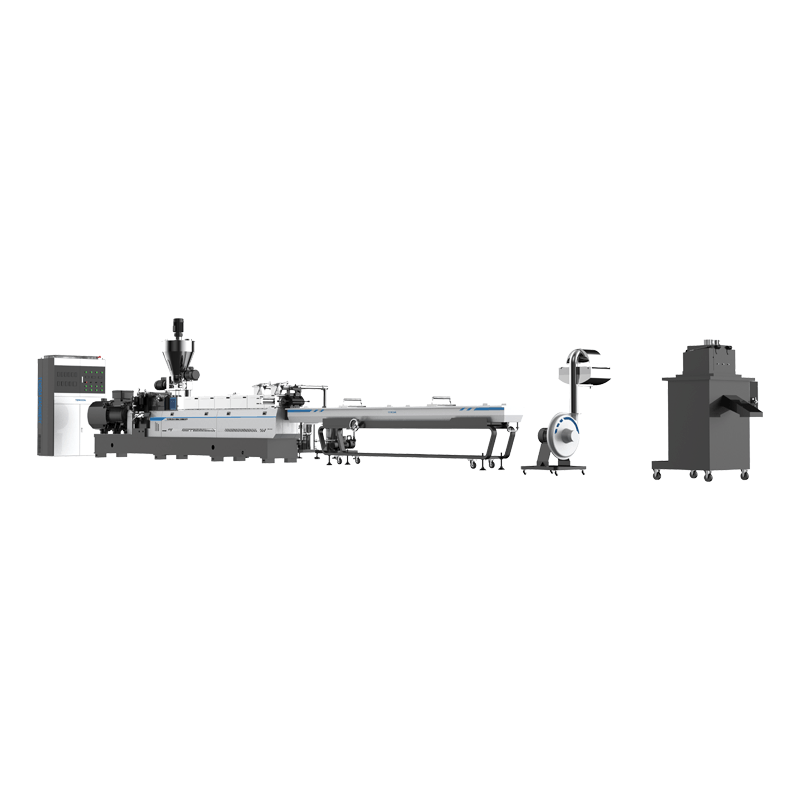

The above is the introduction of TENGDA Plastic Extruder Machine Manufacturers. I hope it will be helpful for everyone to understand the twin-screw extruder equipment. If you want to know more information, please pay attention to the news information of this site.

The Application approach to extruder machine manufacturers is becoming increasingly popular; consequently, there is a surge in the demand for .

Our vision is to realize the tremendous potential of Application by providing plastic extruder machine manufacturers services that consistently meet our customers’ expectations.

Consistency and simplicity go hand in hand. That means aligning TENGDA with the right platforms, speaking to the right customers with the right message, and selling the right idea.

To have a that needs much precaution in handling, it is best to rely only on reliable providers. Nanjing Tengda Machinery Co., Ltd. can provide quality extruder machine manufacturers Application that meet all your requirements for a while meet your individual needs.