What are the characteristics and functions of the twin-screw extruder gearbox?

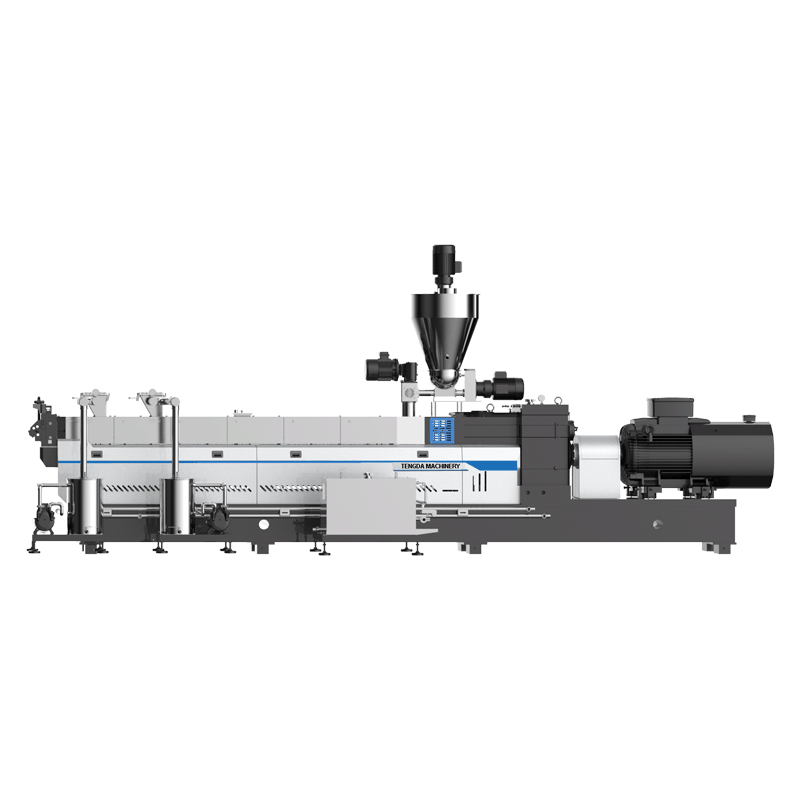

In some extrusion factories, twin-screw extruders are often used as mechanical equipment. Its function is to extrude plastics or other materials. TENGDA Plastic Extruder Machine Manufacturers will introduce below It is an integral part of the equipment, the relevant content of the gear box, the gear box is a very important part of the twin-screw extruder, and its structure directly affects the normal operation of the entire machine. So do you know the characteristics of the twin-screw extruder gearbox? In addition, do you know what the specific function of this gearbox is? It doesn’t matter if you don’t know, let’s learn about it with TENGDA Plastic Extruder Machine Manufacturers.

Features of twin screw extruder gearbox:

A new design of the gearbox transmission system of the twin-screw extruder. The output shaft transmission adopts a power split design, which doubles the torque transmitted by the output shaft, increases the bearing capacity of the whole machine by 50%, and increases the safety factor by 30%.

The gearbox of the twin-screw extruder has a simple structure and is easy to assemble, and can meet the requirements of high torque and high speed for the gearbox of the current co-rotating parallel twin-screw extruder. When installing, ensure that the output shaft of the gearbox is coaxial with the long axis of the distribution box. After the installation is completed, check manually to ensure that the rotation of each component is flexible and there is no stagnation.

The coaxiality of the screw and the output spline shaft of the distribution box directly affects the life of the gear and bearing of the distribution box. During installation, the spline sleeve should be removed and the radial jump of the spline shaft should be checked with a dial indicator, and the screw rod and the spline of the distribution box should be checked with a feeler gauge. Whether the contact between the end faces of the key shaft is good, and the error is eliminated.

The gearbox and distribution box are cooled by circulating water, and the temperature of the cooling water is not higher than 30°C. During operation, if local bearing parts are overheated or there is abnormal noise, stop the machine for inspection, and start operation after troubleshooting.

The role of twin-screw extruder gearbox:

1. Twin-screw extruder gearbox is a very important part of the twin-screw extruder, and its structure directly affects the normal operation of the entire machine.

2. The gear box of the large-scale twin-screw extruder adopts involute cylindrical gear, and its parameters and structure have been optimized and designed by computer.

3. If you want the gearbox to have excellent performance, you can design and research it through the following points.

a. The maximum output speed of the gearbox is generally not greater than 1500r/min.

b. The working environment temperature is 10-40°C. When the ambient temperature is lower than 0°C, the lubricating oil should be heated to +10°C before starting.

c. The gear material of the gear box is made of high-quality high-strength low-carbon alloy steel, which has been carburized and quenched, and adopts the grinding process, so the hardness of the tooth surface is high. Large carrying capacity, low noise, stable operation and high transmission efficiency.

d. The material of the distribution box is ductile iron, the gears are high-strength gears, and there are serpentine cooling water pipes inside.

The above is the introduction of the characteristics and functions of the twin-screw extruder gearbox. After reading the above content, you should have a general understanding of the twin-screw extruder gearbox. If you have other questions, you can consult us.

Nanjing Tengda Machinery Co., Ltd. thinks that customer satisfaction is one of the most important determinants of brand loyalty. High-quality service can be the difference between a one-time buyer and a lifelong repeat customer.

There is always a question of how to extruder machine manufacturers, but have you ever thought about the price point? Go to TENGDA Extruder Machine Manufacturers to get cost effective offer.

If you are looking for best product, then here are some product like Application, plastic extruder machine manufacturers and extruder machine manufacturers in various styles which will surely meet your demand. Visit TENGDA Extruder Machine Manufacturers to know more!