What are the characteristics of plastic extruders?

1. Modularization and specialization

The modular production of plastic extruders can adapt to the special requirements of different users, shorten the research and development cycle of new products, and strive for a larger market share; while specialized production can arrange fixed-point production or even global Procurement, which is very beneficial to ensure the quality of the whole period, reduce costs, and accelerate capital turnover.

2. Efficient and multi-functional

The high efficiency of plastic extruder is mainly reflected in high output, low energy consumption and low manufacturing cost. In terms of function, the screw plastic extruder has not only been used for extrusion molding and mixing processing of polymer materials, but its use has been expanded to food, feed, electrodes, explosives, building materials, packaging, pulp, ceramics and other fields.

3. Large-scale and precise

Achieving large-scale plastic extruders can reduce production costs, which is more obvious in large-scale twin-screw plastic granulation units, film blowing units, and pipe extrusion units. Major technical equipment required for national key construction services, large-scale extrusion and granulation units, one of the three key equipment supporting large-scale ethylene projects, have long relied on imports, so the localization process must be accelerated to meet the development needs of the petrochemical industry.

4. Intelligent and networked

Plastic extruders in developed countries have generally adopted modern electronic and computer control technology. The process parameters of the entire extrusion process, such as melt pressure and temperature, body temperature of each section, main screw and feeding screw speed, and feeding volume, The ratio of various raw materials, the current and voltage of the motor and other parameters are detected online, and the microcomputer closed-loop control is adopted. This is extremely beneficial to ensure the stability of process conditions and improve the precision of products.

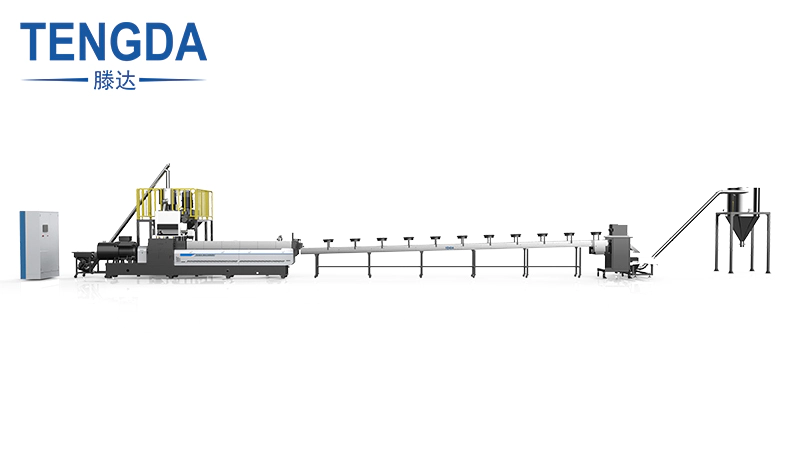

Plastic extruder (main machine) can be used with various plastic molding auxiliary machines such as pipe, film, handle material, monofilament, flat wire, packing belt, extrusion net, plate (sheet), profiled material, granulation, cable coating, etc. Matching to form various plastic extrusion molding production lines to produce various plastic products. Therefore, plastic extrusion molding machinery is one of the widely used models in the plastic processing industry, no matter now or in the future.

Nanjing Tengda Machinery Co., Ltd. is devoted to satisfy our customers with a wide array of the finest using experience.

Nanjing Tengda Machinery Co., Ltd. will accomplish this by exceeding the expectations of our customers while conserving resources and preserving the quality of the environment.

To ensure desired results, it is very essential that you get the right kind of from a certified provider..

We are proud to be a part of helping you to make healthy choices to last a lifetime. Check out our website to see all plastic extruder machine manufacturers Application products we offer at TENGDA Extruder Machine Manufacturers. If you want to start that road to be better, contact us today!