What are the characteristics of twin screw extrusion granulator?

China's extruder products are closely related to strategic new industries, and have the advantages of high efficiency, energy saving and high cost performance. Exports to developed countries are mainly low-end and middle-end, and this part of the consumer demand is rigid. Therefore, the extruder industry There is still a large market space for development. Industry insiders said that in recent years, the market of China's twin-screw extruder enterprises will be more developed, the popularity will be further expanded, and the market competitiveness will be further improved. The proportion of exports to emerging countries will also be greatly increased.

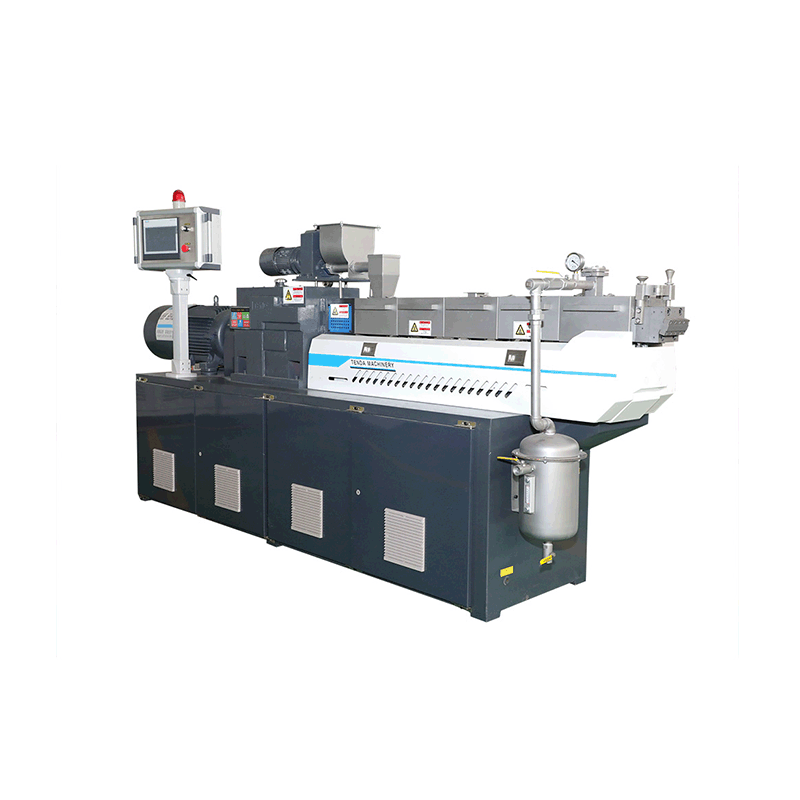

The screw barrel of the twin-screw extruder is made of imported high-strength and high-quality carbon structural steel, which is durable. All recycled materials can be produced after being classified, crushed and cleaned, and can be used for both wet and dry use. From raw material crushing, cleaning, feeding to making pellets are all automated. Make full use of the high-pressure friction uninterrupted heating system to automatically heat production, avoid continuous heating, save electricity and save energy. The split automatic power distribution system is adopted to ensure the safe and normal operation of the motor. The appearance of the machine is beautiful and elegant. Color matching can be painted according to customer requirements.

The structure of the twin-screw extruder system varies according to the application field and operating characteristics. According to the direction of rotation, it is divided into counter-rotation and co-rotation, according to the meshing form, it is divided into meshing type and non-meshing type, and meshing type is divided into full meshing type and partial meshing type. The helix of one screw protrudes into the screw groove of the other screw like a wedge, and the material basically cannot continue to enter the adjacent screw groove from the screw groove, but can only be forced by the screw of one screw. The grooves flow into the grooves of the other screw. Because the screw continues to rotate and the material is repeatedly forced to turn, the material is subjected to better shear mixing, and this structure has a good self-cleaning ability.

Nanjing Tengda Machinery Co., Ltd. continued to crave a more intense, personalized workout experience.

And finally, if you want to find additional resources for Application, simply go to TENGDA Extruder Machine Manufacturers for more.

Nanjing Tengda Machinery Co., Ltd. has been focusing on reaching the ideal profits.

Establish a unique brand as TENGDA that cuts through the clutter, and you'll get you the capital you need to get moving.