What are the characteristics of twin screw extrusion granulator?

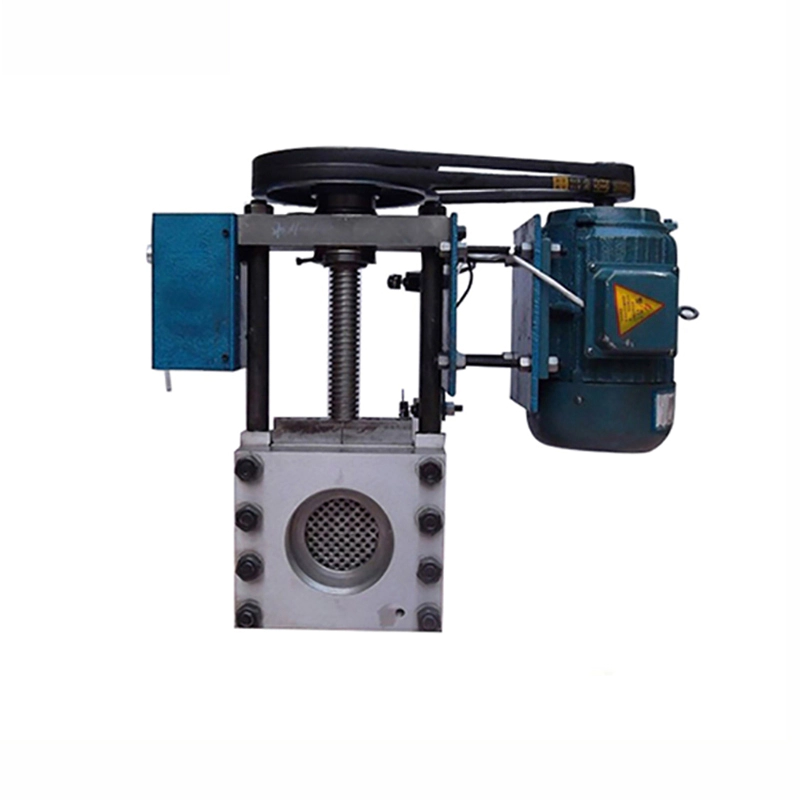

1. The granulation system of the twin-screw extruder granulator can use various methods to meet the requirements, such as water-cooled strand cutting, water-ring die surface eager cutting, eccentric water mist eager cutting, underwater and underwater die surface eager cutting, etc.

2. The twin-screw extruder granulator makes full use of the limited space design to gradually form a spline-shaped structure and a mandrel.

3. The whole machine of twin-screw extruder granulator is installed without foundation, and the ground is required to be flat, and no cement pouring is required.

4. The twin-screw extrusion granulator is a parallel co-rotating twin-screw extruder. Its barrel and screw are designed and manufactured using the principle of building blocks.

5. The main components of the electrical control system of the twin-screw extrusion granulation unit are imported, and can be designed as: sub-main unit control, analog panel display, PLC system, etc. for options.

6. The twin-screw extruder granulator adopts a new type of deceleration distribution transmission system, high-standard design, high-precision gear processing, imported parts for the main bearings, reasonable oil-immersed combined with forced lubrication devices, and chain protection devices to ensure that the The host runs reliably and smoothly.

7. The screw elements of the twin-screw extruder granulator adopt the computer-aided design of the kneading conjugate type. It has excellent self-cleaning function and good interchangeability. Its specifications include conveying block, mixing block, kneading block, countercurrent block and toothed disc, etc. Through appropriate and reasonable combination, material conveying, plasticizing, shearing and Cutting, dispersing, homogenizing, exhausting, building pressure, etc., to complete the technological process of polymer materials.

8. The conventional barrel of the twin-screw extrusion granulator is made of high-quality nitrided steel with surface nitriding treatment or high-performance bimetal alloy sleeve, and tool steel bushing can also be used; the thread components are made of high-quality nitrided steel surface treatment, with high resistance to Grinding high-speed tool steel and special surface treatment methods with corrosion resistance and wear resistance, suitable for various processing.

9. The twin-screw extrusion granulator adopts various structural forms for the feeding system according to the different states of the materials, including single-screw, twin-screw, twin-screw non-meshing type, hollow spring type, double-stage type and metering pump and other volumes. Metered feed. It can also be equipped with loss-in-weight metering feeding to complete higher metering requirements.

plastic extruder machine manufacturers are required in the manufacture of almost every product and extruder machine manufacturers Application is one of the most common machines.

To live healthy, you need to eat healthy; to eat healthy, you need to think healthy; to think healthy, you need to read health; to read healthy, you need to follow TENGDA Extruder Machine Manufacturers.

In a nutshell, is actually an ultimate solution for plastic extruder machine manufacturers and underestimating its value cost you higher than anything else. So grab it before you miss the boat.

With this competency, Nanjing Tengda Machinery Co., Ltd. provide high technology and assist customers to create added value and contribute to the development of producing Application.

Nanjing Tengda Machinery Co., Ltd. will do this by managing our business with integrity and the highest ethical standards, while acting in a socially responsible manner with particular emphasis on the well-being of our teammates and the communities we serve.