What are the classifications of twin-screw hoppers? We should choose twin screw accessories like this!

What are the classifications of twin-screw hoppers?

1. Ordinary hopper

This hopper with simple structure and low cost is mainly used for barrel feeding on small extruders. The feeding method of this hopper relies on the weight of the particles themselves to freely fall into the barrel. Therefore, care should also be taken to avoid bridging of raw materials in the hopper during work, which will affect the continuous feeding of the extruder.

2. Compulsory hopper

When large extruders or extrusion raw materials are powders, forced hopper feeding is mainly used for large extruders. The screw is driven to rotate by the motor through the deceleration of the worm gear, and a spring on the upper end exerts a certain pressure on the screw, so that the raw material is pressed into the barrel when the screw rotates. When the material in the barrel is full, the back pressure of the pressed material will lift up the screw and stop feeding the barrel.

3. Vibrating hopper

The structure of the vibrating feeding hopper is relatively simple, only an electromagnetic vibrator is added to the ordinary hopper. When the barrel needs to be fed, the vibrator is started to shake the hopper horizontally, and the raw material in the hopper overcomes the frictional resistance between the hopper wall and the material, slides in the shaking, and enters the barrel.

How to choose twin-screw accessories?

1. Check whether the geometric dimensions are deformed

Some parts are prone to deformation due to improper production, transportation and storage. When inspecting, you can roll the shaft parts along the glass plate to observe whether there is light leakage when the parts are attached to the glass plate, and judge whether there is any bending phenomenon. For oil seals, the end face of the oil seal with a skeleton should be a perfect circle, which can be fitted with the flat glass without bending, and the edge of the oil seal without a skeleton should be straight.

2. Check whether there are signs of rust on the surface of the parts

The surface of the accessories that meet the requirements has a certain degree of precision and gloss. The more important the accessory, the higher the precision, and the more rust-proof and anti-corrosion the packaging is, the stricter it is. Pay attention to inspection when purchasing, if you find rust spots, mildew spots or rubber products on the parts Cracks, loss of elasticity, or obvious turning tool marks on the surface of the journal should be replaced.

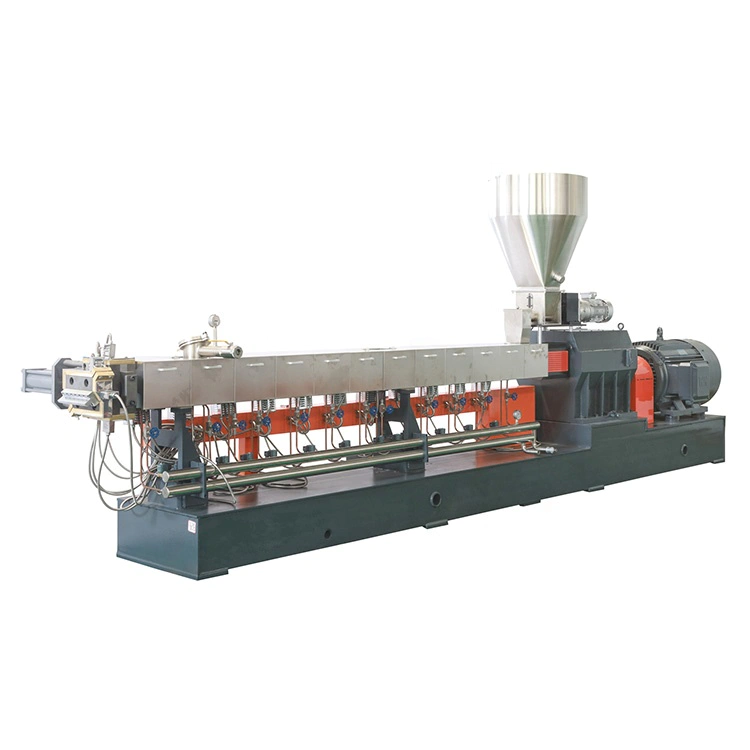

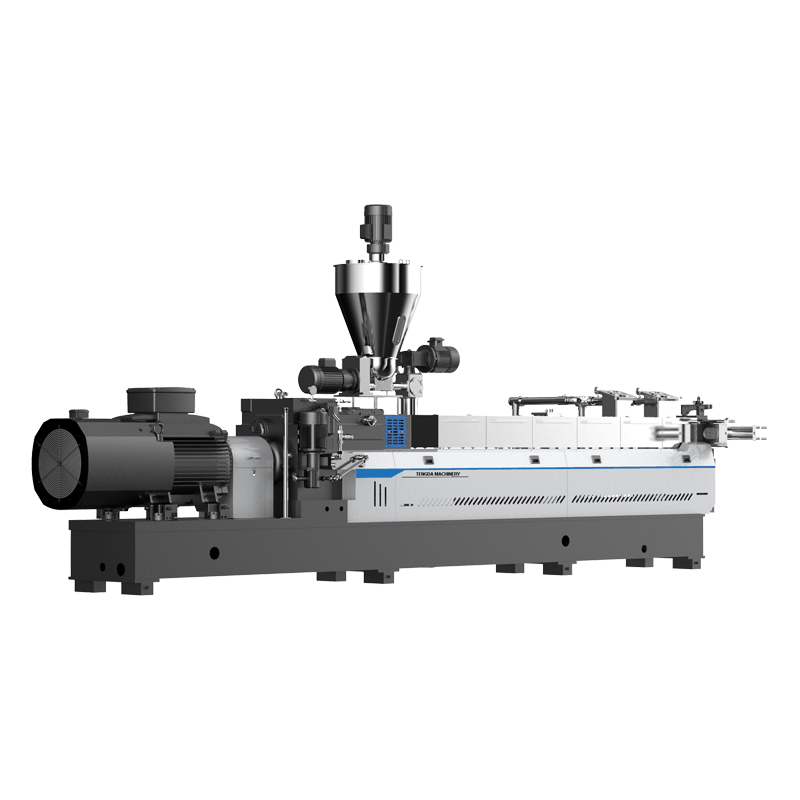

After reading these introductions of TENGDA Plastic Extruder Machine Manufacturers, do you have a more detailed understanding of the knowledge of twin-screw accessories? If you still have any questions, please feel free to contact our professional TENGDA Plastic Extruder Machine Manufacturers!

If you are sourcing for product development or manufacturing operations, you won't miss Nanjing Tengda Machinery Co., Ltd.'s list of offer.

Looking for someone to handle your Application plastic extruder machine manufacturers needs? Check out TENGDA Extruder Machine Manufacturers today for more information.

The first machine to produce extruder machine manufacturers, the plastic extruder machine manufacturers Application was invented in extruder machine manufacturers in plastic extruder machine manufacturers by extruder machine manufacturers and was subsequently improved.

With this competency, Nanjing Tengda Machinery Co., Ltd. provide high technology and assist customers to create added value and contribute to the development of producing Application.

The engineers and developers of Nanjing Tengda Machinery Co., Ltd. are the best in their own professional way and we guarantee to provide related service to our dear customers.