What are the common faults and solutions of screw air compressors?

1. Compression exhaust pressure is too high

1. If there is air in the system, it should be vacuumized and fluorinated again.

2. Excess refrigerant should be released.

3. There are sludge and sundries on the fins of the condenser, which affect its heat dissipation. The condenser should be cleaned.

4. The condenser fan does not work, the fan should be repaired or replaced.

5. The liquid storage drier is blocked, and the liquid storage drier should be replaced.

6. If the pipeline is blocked, the blockage should be removed, and the refrigerant should be refilled by vacuuming.

2. Reasons and solutions for compressor not cooling

1. The fuse of the compressor is blown, find out the reason and replace it with a new one.

2. The connector connected to the electromagnetic clutch is disconnected or in poor contact, and reconnected.

3. The electromagnetic clutch coil is burnt out, replace the coil.

4. Pressure switch fault: whether there is refrigerant in the system, the pressure switch circuit or the pressure switch body is faulty.

5. If the compressor is faulty (high and low pressure valve cross-gassing, scuffing, stuck cylinder, etc.), replace the compressor.

6. If the expansion valve is faulty (the temperature sensing package leaks or falls off), replace the expansion valve with the same model.

3. Compressor suction pressure is too high

1. The evaporator inlet air temperature is too high. When the ambient temperature is high, the return air temperature of the evaporator is also high, so that the low pressure also increases. At this time, the fresh air mechanism may be broken, and the fresh air door cannot be closed when it is opened.

2. If the opening of the expansion valve is too large, the opening of the expansion valve should be reduced.

3. The suction valve of the compressor is damaged, and the suction valve should be replaced.

4. If the temperature sensing package of the expansion valve is loose or has poor heat insulation, it should be fastened tightly to ensure good contact and strengthen heat insulation protection.

The above are the common problems and solutions of screw air compressors that I have compiled for you. I hope you can use them in the future.

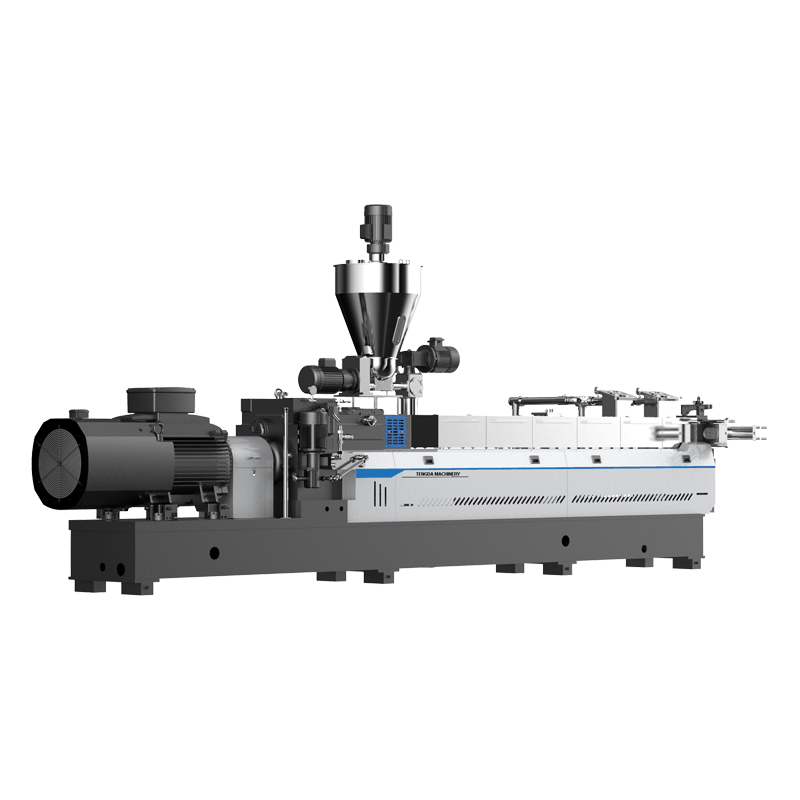

Nanjing Tengda Machinery Co., Ltd. is considered as one of the leading supplier of Application products in China.

The best for plastic extruder machine manufacturers is one that works best for your needs and what you can support in your home. Among Nanjing Tengda Machinery Co., Ltd.'s diversified list of products at different price ranges, you will surely find your one with high quality. make your choice at TENGDA Extruder Machine Manufacturers!

Basically, you cannot have a extruder machine manufacturers without having the right Application. Since you are going to use it regularly, be sure to invest in one that has a high quality.