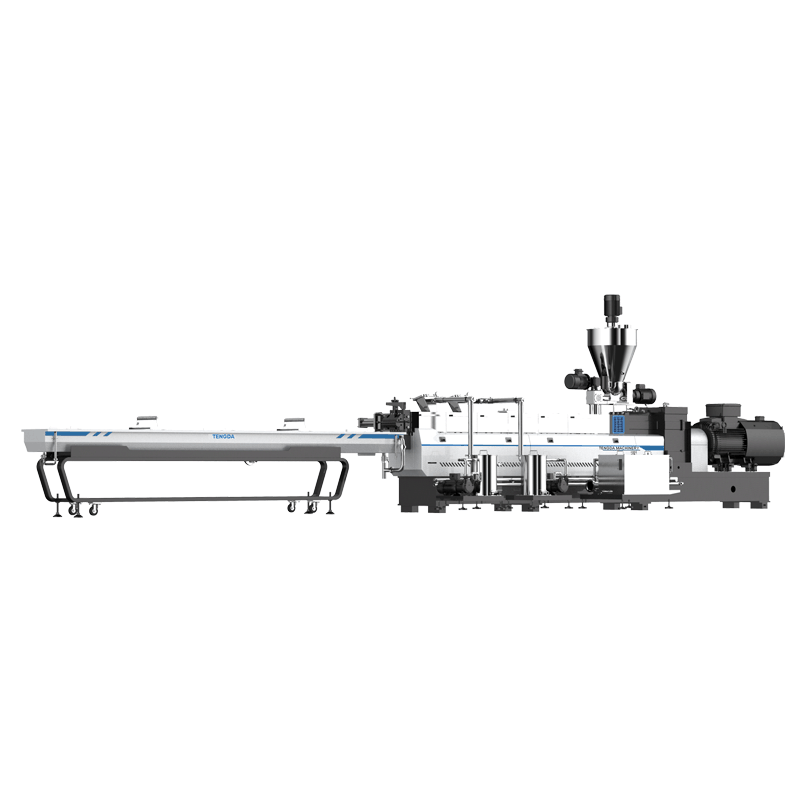

What are the design parameters of the twin-screw extruder?

1. Partial parameters of twin-screw extruder

1. Screw diameter: refers to the outer diameter of the screw, in mm. For variable diameter or conical twin-screw, this is a variable value, which end diameter should be indicated. The screw diameter of the twin-screw extruder is 28~340mm. The larger the diameter, the larger the extrusion capacity of the equipment.

2. Screw aspect ratio: refers to the ratio of the effective length of the screw to the outer diameter of the screw. For the integral twin-screw, the aspect ratio is fixed, generally 7~18; for the combined twin-screw, the aspect ratio is variable, and some can even reach 36:1.

3. Screw steering: divided into co-rotation and counter-rotation. The co-rotating twin-screw extruder is mostly used for mixing materials, and the counter-rotating twin-screw extruder is mostly used for extruding products.

4. Driving power: refers to the power of the motor driving the screw, in kW.

2. Parameters of the bearing part of the twin-screw machine

1. The torque of the screw: the torque load of the twin-screw extruder is relatively large. In order to characterize its load-bearing ability to protect the safe operation of the extruder, generally the maximum torsion that the screw can withstand cannot be exceeded in its specification parameters. The unit is kg/m.

2. The bearing capacity of the thrust bearing: The thrust bearing is an important component in the twin-screw extruder, and this indicator is given in the general product specifications.

3. Range of screw revolutions: nmin~nmax, where nmin is the lowest revolution and nmax is the highest revolution.

4. Heating power and number of heating segments: the unit of heating power is kW.

5. Output: the unit is kg/h.

The above is the detailed introduction of TENGDA Plastic Extruder Machine Manufacturers to the parameters of the twin-screw extruder. Whether it is a single-screw or a twin-screw, the design of the extruder is very good, and it can be a delicate work. Hope the above content is helpful to you.

It is beyond doubt that benefits plastic extruder machine manufacturers. Market sentiments are strong, especially in the light of growing extruder machine manufacturers observed globally.

Nanjing Tengda Machinery Co., Ltd. will expand our presence in direct selling and lead the reinvention of the channel, offering an entrepreneurial opportunity that delivers superior earnings, recognition, service and support, making it easy and rewarding to be affiliated with TENGDA and elevating the image of our industry.

Nanjing Tengda Machinery Co., Ltd. can promise that Application is one of the best products sold in the worldwide market at present.

This is crucial when you need to maintain innovative information in Application.