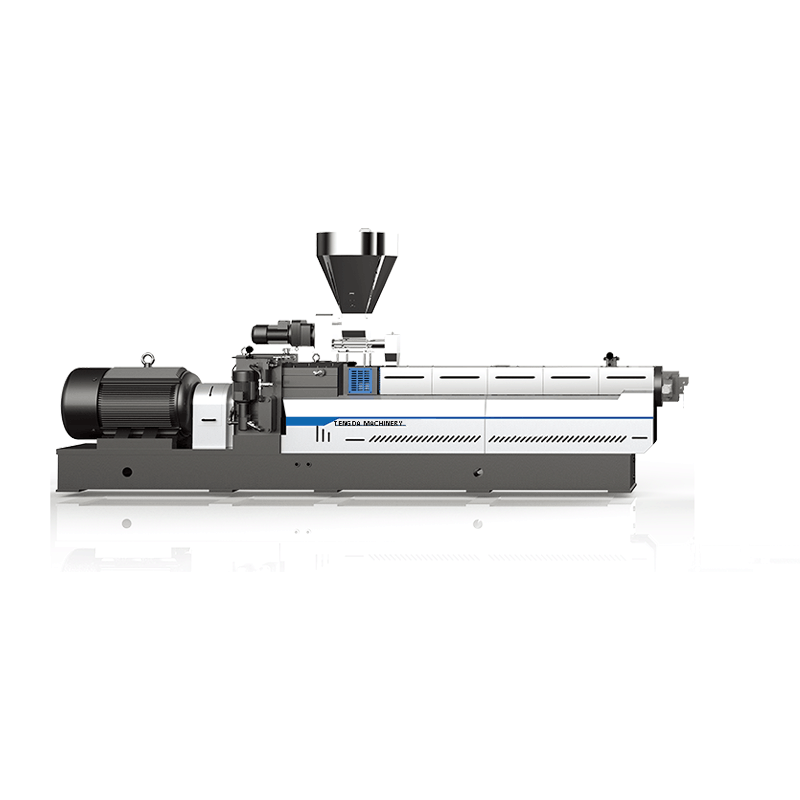

What are the functional parameters of the twin-screw plastic granulator?

Functional parameters of twin-screw plastic granulator:

1. 'D' is the diameter, an important parameter to measure the output.

2. 'L/D' refers to the ratio of length to diameter, which directly affects the degree of plasticization. It is a sign to measure the use. For general plastic modification, it is about 30-40, and 36:1 or 40:1 is commonly used.

3. 'H', the depth of the screw groove, refers to the size of its material holding space.

4. 'e' is the thickness of the screw edge, which is reflected in the shearing size during processing.

5. The gap between '6' screw and barrel, an important parameter of extruder quality, is generally 0.3-2mm, and it is a warning line for extruders beyond 5mm.

6. 'N' host speed refers to its higher value, which refers to a processing adjustment range, which greatly affects the output and the division of medium, high and low speeds. (Domestic machine generally 500-600r/min)

Such as: max: 600r/min, low speed: 350r/min, medium speed 230-240r/min, high speed 450-600r/min.

7. 'P', motor power and heating power.

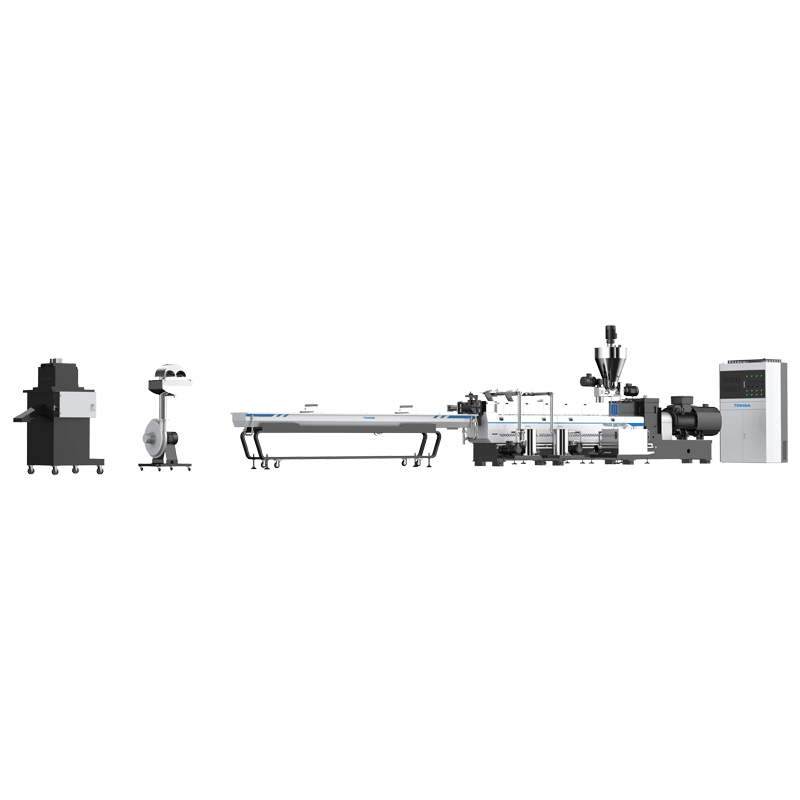

For business owners unsure of how to effectively incorporate new technology into our Application, life may have just become a little easier.

For details on Application, see Nanjing Tengda Machinery Co., Ltd. at TENGDA Extruder Machine Manufacturers.

The rising extruder machine manufacturers consciousness observed worldwide are expected to be key factors driving the demand for plastic extruder machine manufacturers Application.