What are the operation precautions and later maintenance of the laboratory twin-screw extruder?

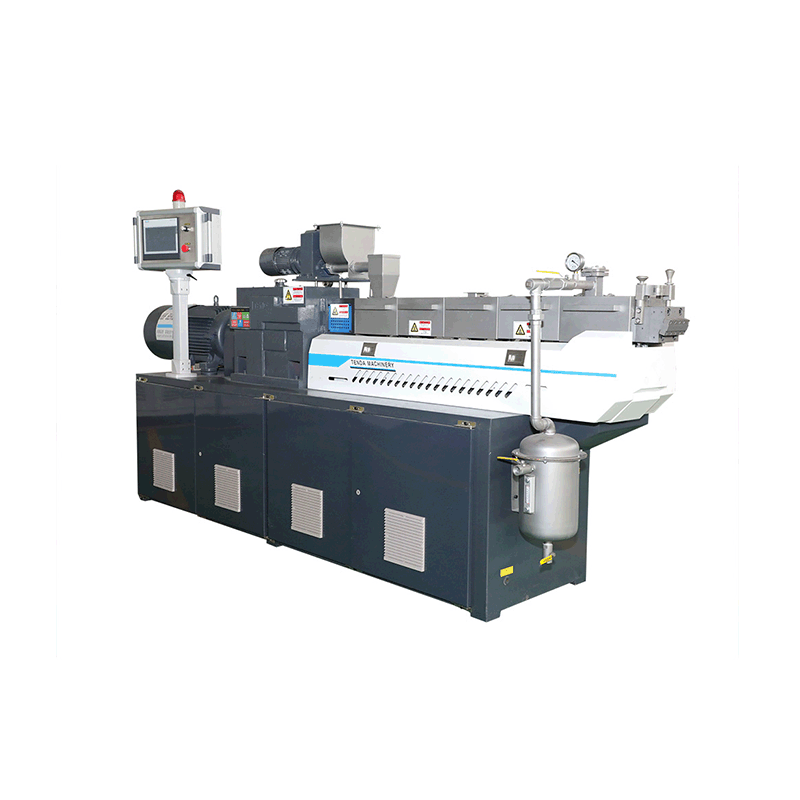

The control system of the laboratory twin-screw extruder is more complicated than that of the single-screw extruder, so certain precautions are put forward for the operation of the twin-screw extruder, including operation and maintenance, daily maintenance and regular The maintenance of the laboratory twin-screw extruder can make the extruder have a longer life. Below, TENGDA Plastic Extruder Machine Manufacturers will briefly introduce the operation precautions and maintenance of the laboratory twin-screw extruder.

Operating points of laboratory twin-screw extruder:

1. In order to ensure the stable performance of the twin-screw extruder and normal production, the assembly work gap between the twin-screw and barrel should comply with the regulations in the table. Check and verify that the direction of rotation of the feeding screw of the twin-screw should meet the production requirements. The heating and constant temperature time of each section of the barrel should generally not be less than 2 hours.

2. Every time before driving, the coupling should be rotated by hand, so that the twin-screws can rotate a few times in the machine barrel. This test rotation should be flexible and free from blockage.

3. Before the twin-screw starts to work, start the lubricating oil pump first, adjust the oil pressure of the lubricating system to 1.5 times the working pressure, check whether there is leakage in each oil delivery system, and adjust the overflow valve after everything works normally to make the lubricating oil The working oil pressure of the system meets the requirements of the equipment instruction manual.

4. When there is no raw material for production in the barrel, the trial running time of the screw at low speed should not exceed 2 minutes. The friction between the screw and the barrel between the screws will scratch the barrel or the screw.

5. In the early stage of production, the screw feeder should feed materials into the barrel evenly. At this time, attention should be paid to the current change of the driving motor for rotating the twin-screw; If the motor is overloaded for a long time, it should be stopped to check the cause of the failure.

6. The rotation of the screw of the twin-screw extruder, the rotation of the feeding screw and the start of the lubricating oil pump motor are interlocked. If the lubricating oil pump motor does not start, the driving motor for twin-screw rotation cannot work; if the twin-screw motor does not start, the driving screw motor for feeding cannot start.

When there is an emergency stop due to equipment failure, press the emergency stop button, and the transmission motors of the three parts will stop working at the same time. At this time, pay attention to the speed control knob of the motor for the feeding screw, the twin-screw drive motor for plasticizing, and the oil pump motor for lubricating oil circulation to return to zero.

Maintenance of laboratory twin-screw extruder:

1. The basis of daily maintenance is to clean the machine and lubricate the moving parts of the extruder. For example, there will be iron filings or other impurities from gear grinding in the gearbox, check the wear of gears and bearings and make records. Clean the gears and replace the gearbox lubricating oil at the same time.

2. After a period of use, it is necessary to conduct a comprehensive inspection of the extruder, check the tightness of all screws, and make a record. Confine the loose threaded parts and check them in real time to prevent failures during operation.

3. Check and adjust the motor, control instrument, various pipelines and working parts. If the power is suddenly cut off during production, the main drive and heating stop, and when the power is restored, each section of the barrel must be reheated to the specified temperature and held for a period of time before the extruder can be started.

4. If the instrument and pointer are found to be fully turned, check whether the contact of the thermocouple and other side lines is good.

5. The inner wall of the cooling water pipe attached to the extruder is prone to scaling and the exterior is prone to corrosion and rust. Careful inspection should be done during daily maintenance. Excessive scale will block the pipeline, and the cooling effect will not be achieved. Severe corrosion will cause water leakage. Measures for descaling and anti-corrosion cooling must be taken during daily maintenance.

6. Focus on checking the brush wear of the DC motor that drives the screw, and regularly check whether the resistance value of the motor is above the specified value. In addition, check whether the connecting wires and other parts are rusted, and take protective measures.

Nanjing Tengda Machinery Co., Ltd. as one who also teaches operations about how we use our whole operating system as a way to gain advantage and create considerable value and capture value in a sector where, in essence, the environment is quite hostile from a competitive point of view.

Nanjing Tengda Machinery Co., Ltd.’s core aim is to afford high-quality products with the concept of manufacturing technology.

Nanjing Tengda Machinery Co., Ltd. can promise that Application is one of the best products sold in the worldwide market at present.

For more Application plastic extruder machine manufacturers reviews, tips and advice on choosing a washer and dryer for you and your family, please visit TENGDA Extruder Machine Manufacturers,where you can also choose the you are looking for.

But we do think that reckoning with supply chains of Application is a really important step. Even super simple switches in material, or sourcing, or shipping, or worker benefits seems like good place to start.