What are the performance characteristics and applications of co-rotating twin-screw extruders?

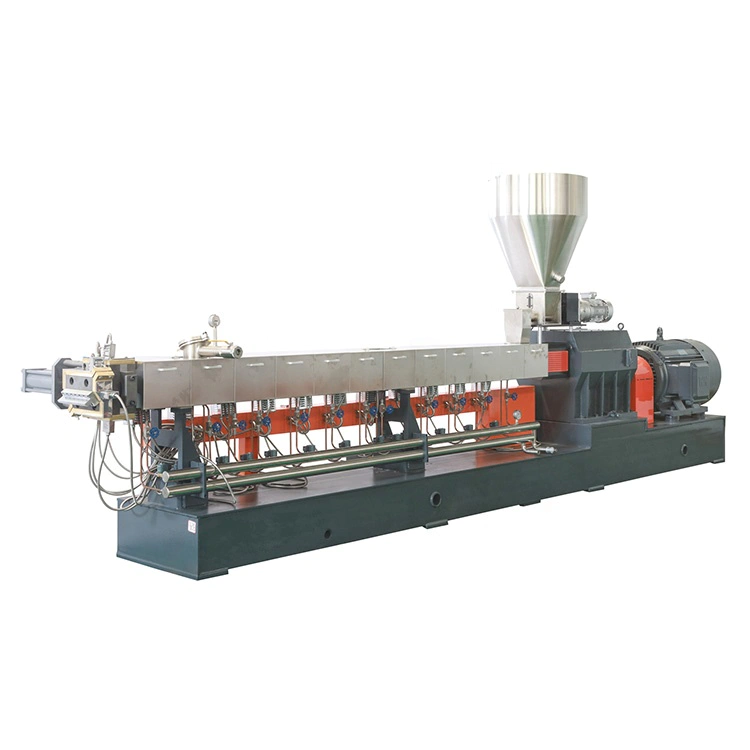

As one of the main types of twin-screw extruders, the co-rotating twin-screw extruder is called an intermeshing co-rotating twin-screw extruder. The extruder series of Nanjing TENGDA Machinery Manufacturing Co., Ltd. is a typical representative. The electrical control components of the international famous brand ABB are adopted, and the transmission box is cast with ductile iron, which increases the rigidity of the box, improves the stability of operation and the safety factor. Today, TENGDA Plastic Extruder Machine Manufacturers will briefly introduce the co-rotating twin-screw The performance of the extruder and its application.

Performance of co-rotating twin-screw extruder

The co-rotating twin-screw extruder has the advantages of high efficiency, good self-cleaning performance, strong dispersion and mixing ability, uniform residence time distribution of materials in the machine, and good adaptability. It is widely used in the mixing and modification of plastics and rubbers. Various additives, plastic mixing, carbon fiber, glass fiber, etc. are the equipment options for polymer modification.

Co-rotating twin-screw extruder adopts feeding system, heating and cooling system, control system, extrusion system, transmission system, etc. The functions of each part are similar to those of single screw, but the structure is much more complicated. Co-rotating twin-screw extruder adopts“Building blocks”The unique design can partially replace the worn screw and barrel elements, avoiding the scrapping of the entire screw or the simplified body, and effectively lowering the maintenance cost.

The modular barrels can be connected by flanges or screw rods, so that ordinary small machines can be connected by tie rods. The barrel is often embedded with bimetallic bushings to increase the wear resistance of the barrel surface. Each barrel is designed with separate heating and cooling, so as to realize the perfect combination of cooling and heating functions.

Each co-rotating twin-screw extruder has various process designs such as mixing, venting, conveying, melting, feeding, pressure building, and extrusion. In the co-rotating twin-screw extruder, the moving speed of the two screws is in the opposite direction. One screw pulls the material into the gap between the meshes, and the other screw is pushed out from the gap, forming a material flow along the screw. presented“∞”The shape orientation of is forced to be conveyed. While the conveying speed remains unchanged, it is not easy to produce local material accumulation and block the exhaust port.

The size of the gap has a great impact on plasticization. The smaller the gap, the greater the shear, and the amount of material passing through will decrease accordingly. Only through reasonable design of shearing and mixing elements can the material be mixed better, thereby accelerating the plasticization, reducing the temperature fluctuation of the material, and greatly improving the output and quality of the extrudate.

Improving production efficiency has always been an important standard for co-rotating twin-screw extruders. Further increasing the screw speed will not cause the temperature of the material to rise and degrade it, thereby ensuring the quality of the product and increasing the productivity of the extruder.

Application of co-rotating twin-screw extruder:

In the process of starting and heating the twin-screw extruder, the temperature of several sections is turned on to start heating. Of course, this method is also commonly used, but this often results in the screw temperature reaching a certain target. , the temperature of the die head has not yet reached, so everyone generally keeps the screw warm in this case, and then waits until the temperature of the die head rises to the set temperature before starting the machine. This method is very power-saving .

The application value of the twin-screw extruder to the twin-screw extruder is gradually becoming more and more popular, and people pay more and more attention to it. In daily life, many customers request to use twin-screw extruders, because this machine can produce some of the most powerful and powerful twin-screws.

With the needs of production and the advancement of technology, the quality requirements of twin-screws are becoming more and more stringent. If it is not for the emergence of twin-screw extruders, it is difficult for twin-screws that can really meet the needs of life to really play their due role. Work brings convenience.

The above is the relevant introduction about the performance characteristics and application of the co-rotating twin-screw extruder. If you want to know more about it, please pay attention to the news section of this site.

Finding a reliable solution for the Application extruder machine manufacturers not only supports operation of the entire system but also enhance the beauty of your workplace.

Nanjing Tengda Machinery Co., Ltd. take prudent risks and work together to assure our success and profitability in the future.

Consumers like these are interested not just in Application they will spend their money on, but also in the human and environmental impact of the supply chain that produces those goods.

Deeper connections between TENGDA and Applicationare made when you go beyond the white lights of a corporate space.

![New design polymer process extrusora de plastico[twin screw extrusor]](https://img80003272.weyesimg.com/uploads/www.njtdjx.com/images/16272689525083.jpg?imageView2/2/w/1000/q/100/format/webp)