What are the reasons for the wear of twin-screw fittings? Its failure has these effects on the machine!

Causes of wear of twin-screw fittings:

1. Ordinary wear and tear

When plastic base particles, auxiliary materials and additives enter the cylinder for mixing and kneading, there will inevitably be friction, which will cause the cylinder and threaded components to wear. Especially fillers such as calcium carbonate and glass fiber, these substances tend to have much higher friction on metal materials than molten plastics.

2. Corrosion and wear

The auxiliary materials and additives may be corrosive, directly corroding the inner wall of the cylinder, resulting in a reduction in the life of the cylinder.

3. Working condition

The working environment of the extruder is very harsh, and the melting temperature of plastics is generally high. For example, the melting temperature of polycarbonate reaches about 240°C, that of nylon reaches about 280°C, and that of PPS reaches about 290°C. At high temperatures, the physical properties of the metal degrade, resulting in reduced barrel life.

4. There are moisture, air, oxygen and other components in the cylinder

When the cylinder is mixed with oxygen and water vapor, the cylinder wears more severely.

The impact of twin-screw accessories failure on the machine:

1. The air compressor station has poor ventilation and heat dissipation

(1) The temperature at the rotor outlet rises to cause a high temperature trip.

(2) The fan motor is overloaded.

(3) The increase in the temperature of the air outlet increases the load of the cold dryer. It is recommended that customers add air ducts and exhaust systems.

2. The non-return valve failed to close

(1) After the machine was started, the oil tank could not rise and the air compressor could not be loaded.

(1) On-site air will flow back into the machine, causing the oil tank pressure to fail to drop when the machine is empty, and causing the air compressor to spray oil after parking. Remove the pressure check valve for maintenance and replace it with a new one if it fails.

3. The drive belt is broken

(1) During operation, the pressure of the oil tank will drop to 0kg, and the output pressure will stop. Check the cause of the broken belt and install a new belt.

4. The intake valve cannot be closed

(1) After the air compressor is empty, the pressure will continue to rise and cause the safety valve to exhaust.

(2) Cooling oil is poured out from the air intake when the car is parked. Remove the intake valve for maintenance, and replace it with a new one if it fails.

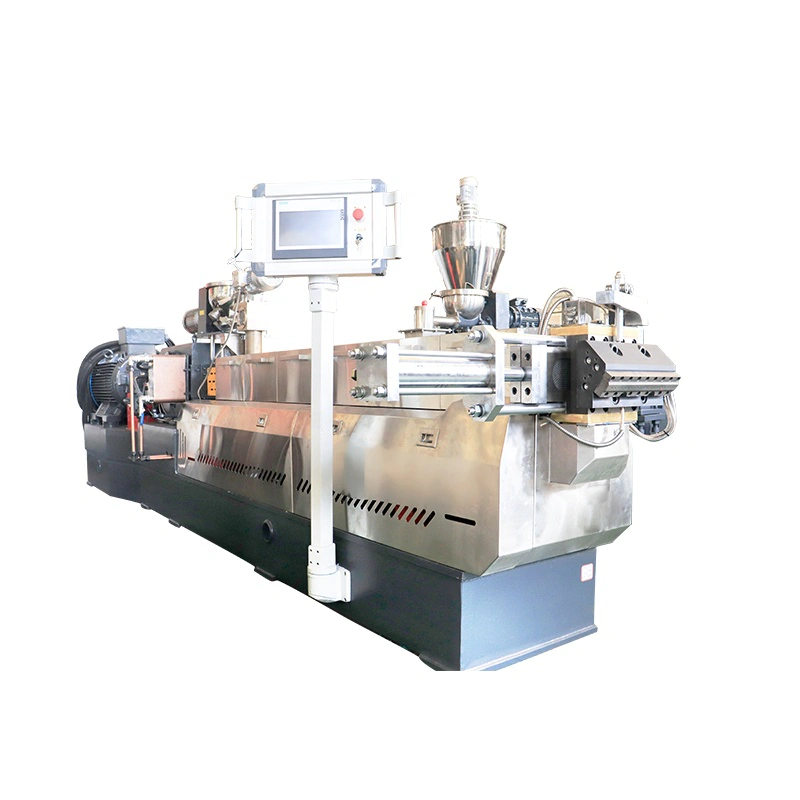

To sum up, after reading the introduction of TENGDA Plastic Extruder Machine Manufacturers about the causes of twin-screw accessories wear and the impact of accessories failure on it, if you still have doubts, welcome to consult us!

Many of us have heard about Application and seen some of these units in operation in extruder machine manufacturers, plastic extruder machine manufacturers and extruder machine manufacturers spaces.

Have you been looking for a good Application plastic extruder machine manufacturers provider? If so, we suggest that you check out Nanjing Tengda Machinery Co., Ltd. at TENGDA Extruder Machine Manufacturers.

Application can be applied in different ways as extruder machine manufacturers.

Obviously, financial return is important in manufacturing Application, but I think that's not enough. I think many customers want to support something they really believe in.

Did I make the right decision? Am I saving money? Would I do it this way again? Yes, yes and yes if you choose to visit TENGDA Extruder Machine Manufacturers and make your enquiry.