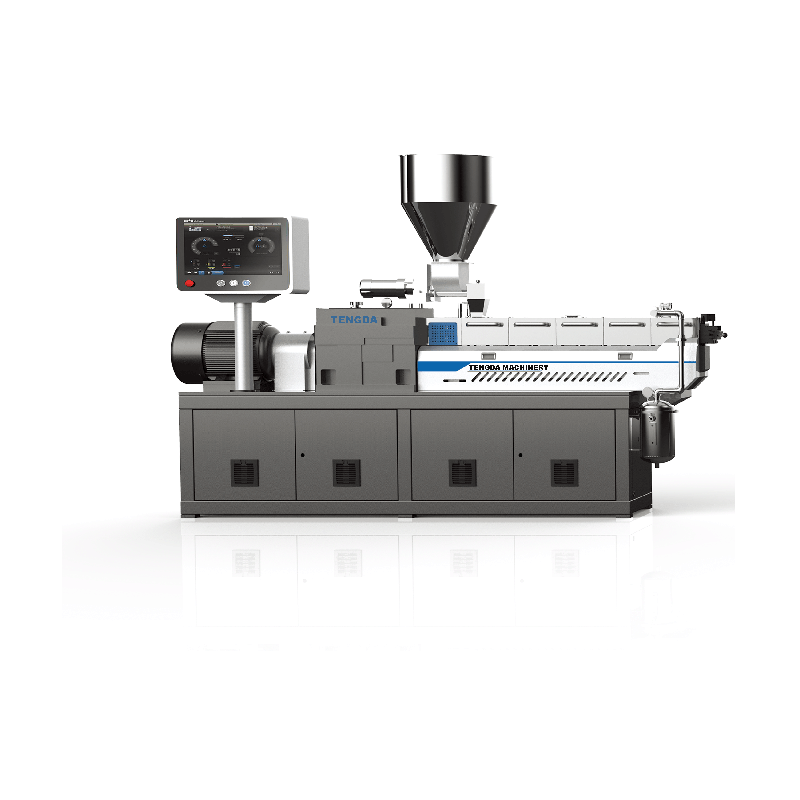

What are the structural characteristics of the twin-screw extruder? Its advantages are mainly reflected in these aspects!

Structural features of twin-screw extruder:

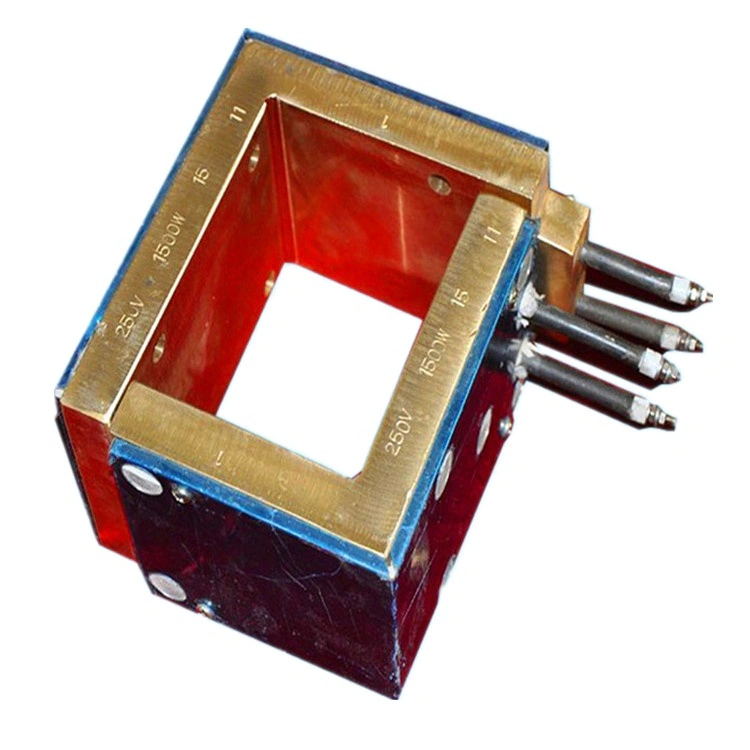

1. In the past, the barrel of the twin-screw extruder was integral and could not be opened. The split type twin-screw extruder is a split type, consisting of upper and lower half cylinders, and the lower half cylinders are fixed on the frame. The upper half cylinder is connected with the lower half cylinder through a worm gear reducer. Usually use two rows of bolts to fasten the upper half cylinder and the lower half cylinder. When it is necessary to open the cylinder, just loosen the bolt and turn the worm gear box by hand to turn the handle to open the bucket.

2. The screw is composed of various screw blocks installed on the mandrel and the inner lining of the barrel. The sleeve can be adjusted according to different screw blocks, and the ideal structure of the screw elements can be flexibly combined according to the process requirements of the material variety to realize the transportation of materials, Plasticizing, refining, shearing, and discharging can well solve the contradiction between the universality and specificity of the screw, which is generally difficult to consider, and achieve the purpose of multi-purpose and multi-functional in one machine.

What are the advantages of twin-screw extruders?

1. The twin-screws of the main engine are high-speed co-rotating meshing type, which can produce extremely strong and complex material transfer and exchange, splitting, shearing and kneading in various screw threads and mixing elements.

2. These functions can be fully and freely adjusted and controlled by changing the screw configuration and operating process conditions to meet the requirements of various processes.

3. Accurate measurement and reasonable feeding method are the key to strictly implement the formula, and also the beginning of ensuring product quality. We are equipped with a variety of feeding methods according to the performance of the material and the needs of users.

4. The twin-screw extruder adopts an advanced and beautiful control system, and most of the control components are imported, with good quality and high sensitivity. The operating parameters of the host are as follows: current, voltage, temperature, and torque are very intuitive.

5. The system is equipped with drawing water cooling, thermal cutting water cooling and thermal cutting air cooling. It can be configured according to different materials and user requirements. The operation is very convenient, and the requirements for operators are not high.

The above is the knowledge about twin-screw extruder introduced by TENGDA Plastic Extruder Machine Manufacturers. After such a detailed introduction by TENGDA Plastic Extruder Machine Manufacturers, if you have any doubts, please feel free to contact us!

In the office, various are considered essential since they are used to achieve particular tasks in the office. Among these , Application, extruder machine manufacturers, and plastic extruder machine manufacturers are widely used.

Applied Materials’ mission is to be the leading supplier of Application worldwide-through innovation and enhancement of customer productivity with systems and service solutions.

Making a few technical tweaks to the way you structure and distribute Application could be the difference between an engaging, thought-provoking product and a perfunctory one.