What are the working characteristics of twin screw extruders?

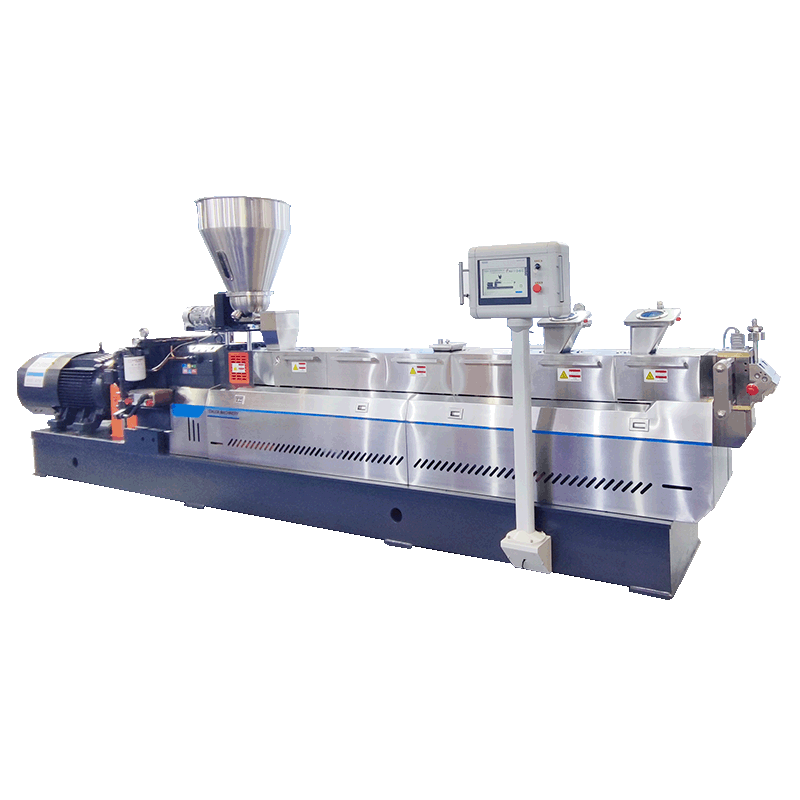

Nanjing twin-screw extruder manufacturer information: Twin-screw extruder has the characteristics of high efficiency, high quality and high output. It is widely used in the processing of a variety of materials, such as: dense color masterbatch, thermosetting plastic mixing and extrusion , Hot melt adhesive, glass fiber reinforced, etc. From the point of view of the principle of motion, the twin-screw extruder can be divided into non-meshing type, counter-rotating meshing and co-rotating meshing.

Today, Tengda Machinery, a manufacturer of twin-screw extruders in Nanjing, will give you a detailed introduction to their work characteristics.

1. Non-intermeshing twin-screw extruder. The center distance between its two screws must be greater than the sum of the radii of the two screws, only in this way can it work normally.

2. Counter-intermeshing twin-screw extruder. The twin-screw extruder can carry forward conveying, and the gap between its two screw groove screws is very small than the gap in the same direction.

3. Co-rotating intermeshing extruder. There are two types of twin-screw extruders, high-speed and low-speed. The high-speed is mainly used for processing special polymers; the low-speed is mainly used for profile extrusion. The high-speed co-rotating extruder has a closely matched spiral shape. The screw can be designed to have a certain screw gap, so that the screw has a closed self-cleaning effect. This twin-screw extruder is also called a compact self-cleaning co-rotating twin-screw extruder; the low-speed extruder has a compact The geometry of the intermeshing screw, in which the shape of the ridge of one screw and the shape of the other screw closely match, which is the so-called conjugate screw shape.

Today’s twin-screw extruders are developing in the direction of low energy consumption, high speed and high torque. It greatly improves the production efficiency of enterprises. It is used in the processing of heat-sensitive materials and high-viscosity materials. With unique advantages and deep trust of corporate users, friends who need twin-screw extruders can contact the staff of Tengda Machinery, a manufacturer of twin-screw extruders in Nanjing.

Nanjing Tengda Machinery Manufacturing Co., Ltd., a leader in the Ru0026D and manufacturing of twin-screw extruders and twin-screw pelletizers, specializes in the Ru0026D and manufacturing of various plastic processing and extrusion equipment until turnkey projects . The product line covers twin-screw extruder, twin-screw granulator, plastic extruder, plastic pellet machine, plastic granulator and supporting auxiliary equipment, etc.

There are many issues that affect extruder machine manufacturers, which has led to the need of getting specialists trained in certain areas so as to handle all issues that may arise as well as Application products that can solve plastic extruder machine manufacturers problems.

Boasting good reputation in the industry, Nanjing Tengda Machinery Co., Ltd. is the leading Application supplier, offering high quality and Application services for homes and enterprised all over the world. More info on TENGDA Extruder Machine Manufacturers.

Application are raising the stakes of social marketing, but they also ease the sales process by providing ways for extruder machine manufacturers to effectively interact with customers.

While manufacturing Application, we always pay attention to the technology and quality of the product.