What are the working characteristics of twin screw extrusion granulator?

There are many types of twin-screw extruders because they can be classified according to a variety of standards, and their working characteristics vary greatly. Take positive displacement conveying capacity as an example, not all twin-screw extruders have positive displacement conveying capacity. , even if there is a difference in degree, it is a very difficult task to analyze the working characteristics of the twin-screw in detail and without omission. The twin-screw extruder can be classified at different angles according to whether the screw meshes or not and its rotation. One of the main differences between the twin-screw extruder and the single-screw extruder is that the conveying power of the solid material in the single-screw extrusion process is solid The friction force in the conveying section, and the melt conveying is accomplished by the drag of the melt generated by the relative motion between the screw and the barrel to overcome the resistance of the head, so the material conveying behavior of the single-screw extrusion process is strongly dependent on the The friction characteristics of the processed object in the solid state and the viscous characteristics of the molten state. This solid and melt conveying mechanism is not only inefficient and energy-intensive, but also prone to instability, because the friction properties of solids are affected by many factors such as temperature, pressure, screw and barrel. The surface roughness of the solid state affects the solid shape, and the soft and hard program that affects the working characteristic line of the melt conveying section obviously depends on the viscous properties of the melt.

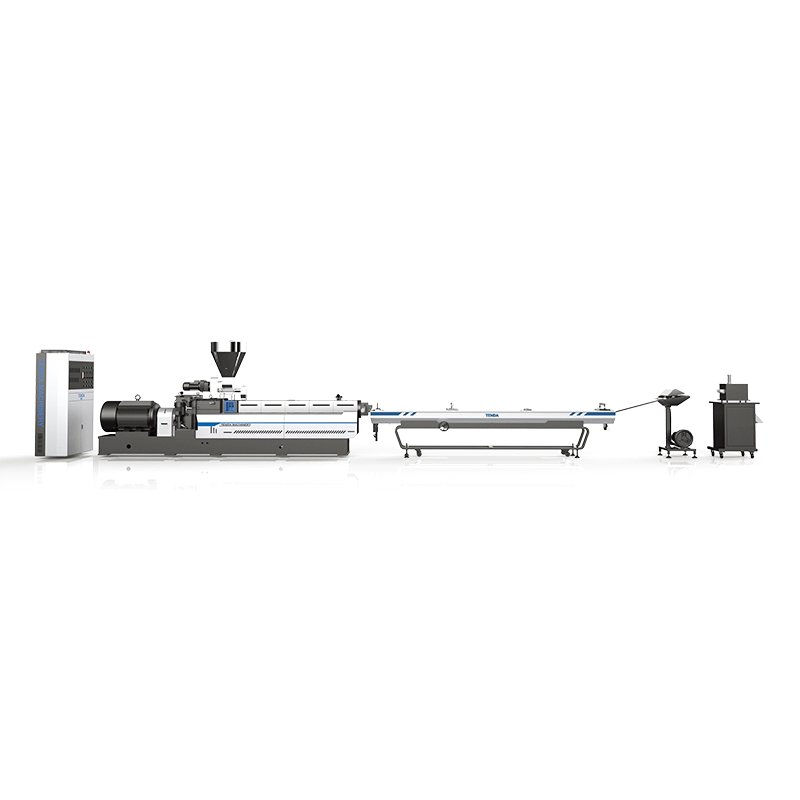

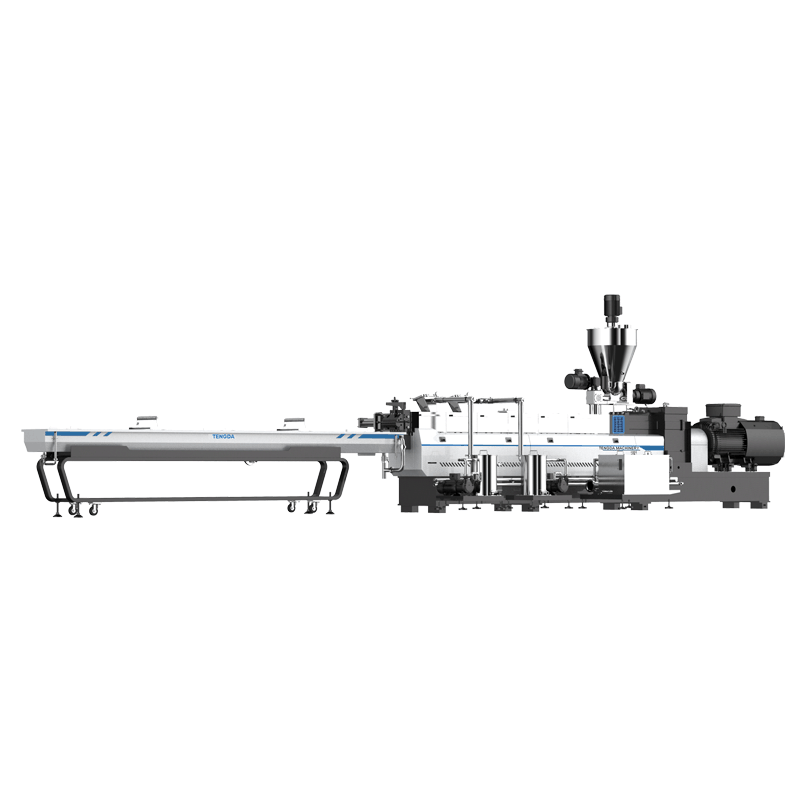

The twin-screw extruder granulator is composed of a transmission device, a feeding device, a barrel and a screw, and the functions of each part are similar to that of a single-screw extruder. The difference from the single-screw extruder is that there are two parallel screws in the twin-screw extruder pelletizer, which are placed in the '∞'-shaped cross-section feedstock.

Nanjing Tengda Machinery Co., Ltd. devises a regular, independent, transparent and objective assessment mechanism to evaluate country performance.

Through our culture, our drive and the expertise of each individual employee, Nanjing Tengda Machinery Co., Ltd. is uniquely positioned to provide best-in-class services to a global customer base.

People are more likely to listen to an expert than just anyone off the street. So, while pack mentality is important, having a relevant expert speak to the effectiveness of a brand's product as TENGDA is essential to converting new consumers as well.

Unlike the extruder machine manufacturers, the is more flexibly used in accasions where plastic extruder machine manufacturers .