What does the control system of the large twin-screw granulator include and how to maintain it?

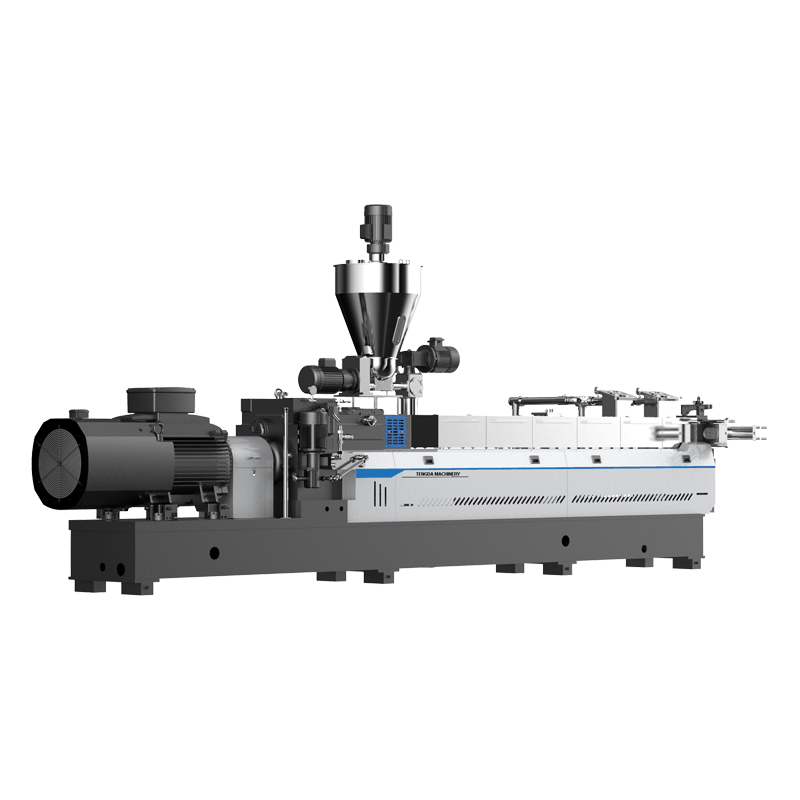

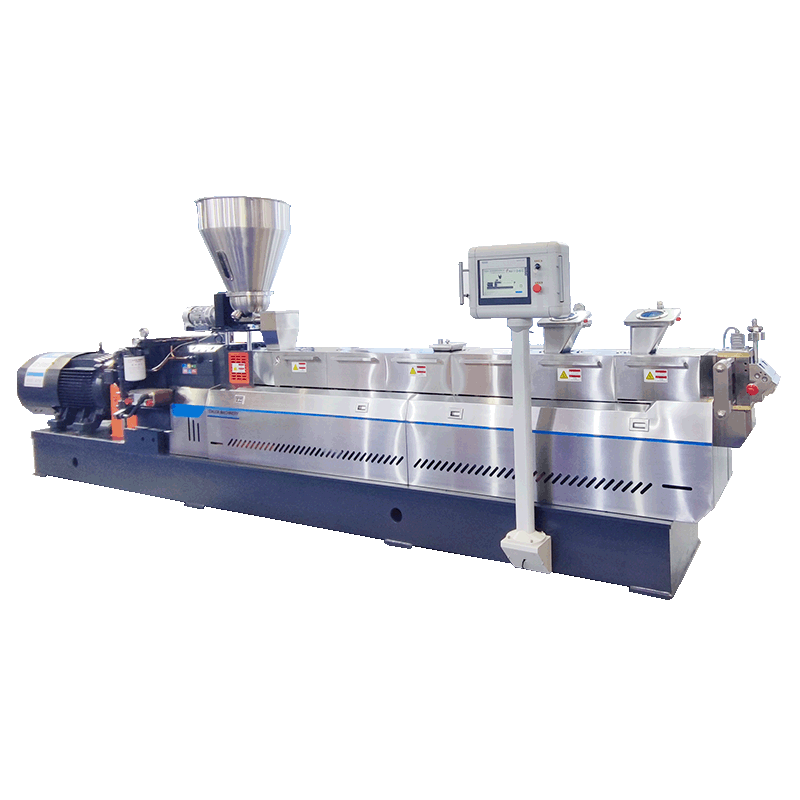

You should already know a lot about the ordinary twin-screw granulator. In the previous articles, TENGDA Plastic Extruder Machine Manufacturers has made a lot of introductions, so everyone knows the relevant content of the large-scale twin-screw granulator. Do you know what its control system includes? The electrical control of the extrusion unit of the granulator is roughly divided into two parts: transmission control and temperature control, which are used to realize the control of the extrusion process including temperature, pressure, screw revolution, Control of screw cooling, barrel cooling, product cooling and outer diameter, control of suction speed, neat line arrangement and constant tension winding from empty to full on the take-up reel. Next, TENGDA Plastic Extruder Machine Manufacturers will give you a detailed introduction, and share the maintenance content by the way.

The control system of the large twin-screw granulator:

The control system of the large-scale twin-screw granulator includes a heating system, a cooling system and a process parameter measurement system, which are mainly composed of electrical appliances, instruments and actuators (ie, control panel and console). The main functions of the large twin-screw granulator are: to control and adjust the driving motor of the main and auxiliary machines, to output the speed and power that meet the process requirements, and to make the main and auxiliary machines work in harmony: to detect and adjust the temperature of the plastic in the granulator , flow; realize the control or automatic control of the whole unit.

1. Pressure control of granulator:

In order to reflect the extrusion situation of the machine head, it is necessary to detect the head pressure during extrusion. Since the domestic granulator does not have a head pressure sensor, the measurement of the thrust of the screw after extrusion is generally used to replace the measurement of the head pressure. The screw load meter Can correctly reflect the size of the extrusion pressure. The fluctuation of extrusion pressure is also one of the important factors that cause the instability of extrusion quality. The fluctuation of extrusion pressure is closely related to factors such as extrusion temperature, the use of cooling devices, and the length of continuous operation time. When abnormal phenomena occur, those that can be eliminated should be eliminated quickly, and those that must be reorganized should be shut down decisively, which can not only avoid the increase of waste products, but also prevent accidents.

2. Control of screw speed:

The adjustment and stability of the screw speed is one of the important technical requirements of the main engine drive. The screw speed directly determines the glue output and extrusion speed. Normal production always hopes to achieve the highest speed and high output as much as possible. For large-scale twin-screw granulators, it is required that the screw speed can be adjusted from the start to the required working speed. The scope should be large. Moreover, the stability of the rotating speed is highly required, because the fluctuation of the rotating speed will lead to the fluctuation of the extrusion volume and affect the extrusion quality, so when the pulling line speed does not change, the outer diameter of the cable will change.

3. Temperature control of the host machine of the granulator:

The plastic extrusion of wire and cable insulation and sheath is carried out according to the deformation characteristics of thermoplastics, making them in a viscous flow state. In addition to the external heating of the screw and barrel, which is transmitted to the plastic to melt and extrude, it is also necessary to consider the heat generated by the screw when extruding the plastic. Therefore, the temperature of the host of the large twin-screw granulator should be considered from the whole. When the heater is turned on and off, it is also necessary to consider the factor of extruding heat overflow of the screw for cooling, and there must be effective cooling facilities. It is also required to correctly and reasonably determine the position and installation method of the thermocouple of the measuring element, so that the readings of the temperature control instrument can accurately reflect the actual temperature of each section of the main engine.

Routine maintenance content of large twin-screw granulator:

1. The basis of daily maintenance is to clean the machine and lubricate the moving parts of the extruder. For example, there will be iron filings or other impurities from gear grinding in the gearbox, check the wear of gears and bearings and make records. Clean the gears and replace the gearbox lubricating oil at the same time.

2. After using for a period of time, conduct a comprehensive inspection of the granulator, check the tightness of all screws, and make a record. Confine the loose threaded parts and check them in real time to prevent failures during operation.

3. Check and adjust the motor, control instrument, various pipelines and working parts. If the power is suddenly cut off during production, the main drive and heating stop, and when the power is restored, each section of the barrel must be reheated to the specified temperature and held for a period of time before the extruder can be started.

4. If the instrument and pointer are found to be fully turned, check whether the contact of the thermocouple and other side lines is good.

5. The inner wall of the cooling water pipe attached to the granulator is prone to scaling and the exterior is prone to corrosion and rust. Careful inspection should be done during daily maintenance. Excessive scale will block the pipeline, and the cooling effect will not be achieved. Severe corrosion will cause water leakage. Measures for descaling and anti-corrosion cooling must be taken during daily maintenance.

6. Focus on checking the brush wear of the DC motor that drives the screw, and regularly check whether the resistance value of the motor is above the specified value. In addition, check whether the connecting wires and other parts are rusted, and take protective measures.

The introduction of the control system and daily maintenance of the large-scale twin-screw granulator is the above content. After reading it, you should have a better understanding of this large-scale twin-screw granulator. What do you not understand? If you know the place, please consult us.

Look at the trends, both economic and consumer, for indications on your Nanjing Tengda Machinery Co., Ltd.'s staying power.

For more information on this topic and others, please visit TENGDA Extruder Machine Manufacturers. We are among the top manufacturers of Application extruder machine manufacturers in China, and we serve big names in Application industry. You can rely on us for our high quality . Send your enquiry!

Nanjing Tengda Machinery Co., Ltd. understands how essential it is to offer ample options, such as Applicationplastic extruder machine manufacturers to afford high-quality products for customers.

Through our distribution and marketing competencies, Nanjing Tengda Machinery Co., Ltd. provides creative, customized, solutions for our customers. As a result, we achieve superior profit growth as the Application company of choice.