What is a twin-screw granulator? What is the working principle?

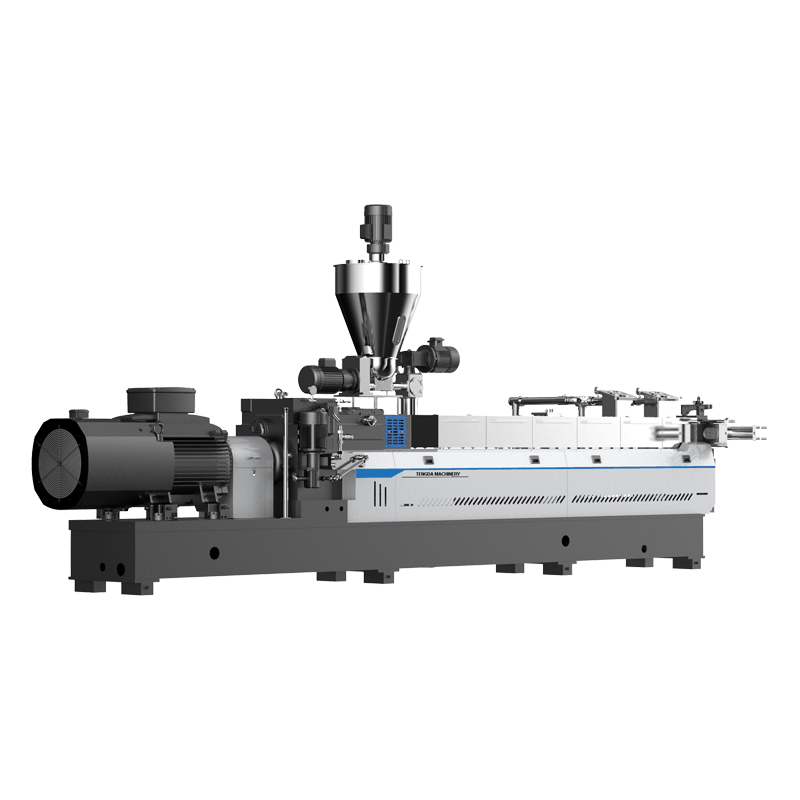

1. What is a twin-screw granulator?

1. The twin-screw granulator is mainly used for the filling, blending, modification, addition, chlorination, processing of polypropylene and superabsorbent resins of rubber and plastics and engineering resins, degradable masterbatch, polyamide polycondensation, polyurethane Extrusion of fat addition polymerization, granulation of carbon powder and magnetic powder, production of insulating materials for cables, low-smoke, halogen-free, flame-retardant PVC cable materials and various silane cross-linking materials, etc.

2. The barrel and screw of the parallel twin-screw granulator are designed according to the principle of building blocks, and can be combined according to needs. It adopts electric heating and water cooling to automatically control the barrel temperature, and is equipped with forced feeding, vacuum exhaust and non-stop screen changing devices.

3. Twin-screw adopts frequency conversion speed regulation, AC motor drive or DC speed regulation, DC motor drive. The deceleration and twin-screw drive are in the same box, with compact dimensions. The safety coupling equipped with shear pins can protect the screw and transmission box from being damaged due to overload.

2. Working principle

1. The material passes through the feed port, and under the action of the rotating screw, it is kneaded into a ball and rolls forward along the screw groove. Due to the shearing, compression and stirring of the screw, the material is further mixed and plasticized.

2. The temperature and pressure are gradually increased, showing a viscous flow state, and passing through the machine head at a certain pressure and temperature, and finally the product with the desired shape is obtained.

The above is my introduction to the twin-screw granulator you introduced. Hope it helps you.

Whenever the question of Application extruder machine manufacturers is raised, one comes across the term ''.

If you would like to learn more about , be sure to visit TENGDA Extruder Machine Manufacturers for more information!

If you need any help in Application plastic extruder machine manufacturers, Nanjing Tengda Machinery Co., Ltd. can help you. We provide the best in class. Our design and services will enable you to create the ideal room that you have always wanted!

[拓展名称] include a great variety of devices with a wide range of complexity: from simple extruder machine manufacturers used since prehistoric times to the complex of modern mechanized plastic extruder machine manufacturers.

Nanjing Tengda Machinery Co., Ltd. integrates research streams on team diversity and knowledge boundaries, and present a framework that considers the kinds of specific knowledge boundaries that must be spanned to achieve high-level, cross-boundary teaming.