What is the difference between a plastic extruder and an injection molding machine

1. Analysis from the aspect of molding process:

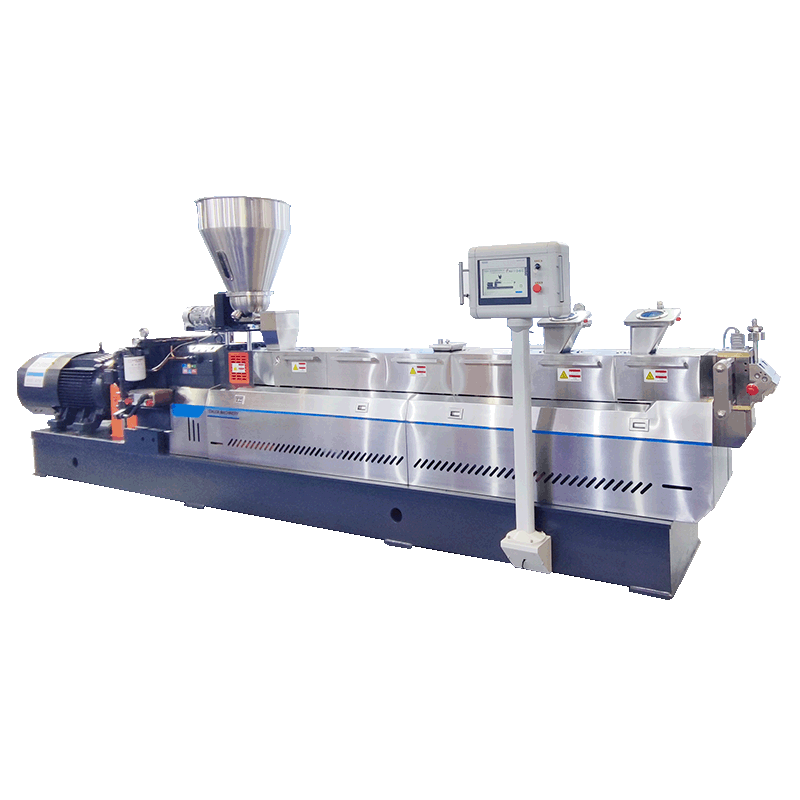

1. The plastic extruder is to extrude the flame melting plastic through a fixed-shaped extrusion port under the action of the screw, and then cut it after water-cooling and shaping under the action of the tractor. It is mainly used for mass continuous production of various products with the same cross-section, such as pipes , rods, profiles, etc., can also be used for plastic modification and granulation. Its plastic processing is called extrusion molding process.

2. Injection molding machine injects molten plastic into the mold, and the product is made after cooling. It has a wide range of uses, and it is used in different places depending on the plastic. This process is called injection molding process.

Second, from the analysis of processing materials

The materials processed are also different between the extruder and the injection molding machine, and the viscosity of the materials is different. Injection molding requires plastic raw materials to flow in the mold, and the runners are generally curved and narrow, so plastics are required

The fluidity of raw materials must be absolutely

it is good.

Third, from the working principle

1. The injection molding machine injects the plastic particles into the closed mold cavity after melting, and after the cavity is filled, the work is suspended first, and the plastic is shaped into a certain shape by cooling, and then the work starts again after the mold is opened. Such as plastic cups, plastic basins and other plastic products. 2. The plastic extruder is to continuously extrude plastic particles through the mold after melting, such as plastic pipes, plastic plates, etc., and then cut them off in the subsequent process. The two machines not only process different materials, but also have different structures of the rods. The above content is organized and published by the experimental equipment. I hope it will be helpful to everyone. Shiyan Instruments focuses on the R&D and production of extruders, plastic extruders, and small extruders. Welcome to consult and order.

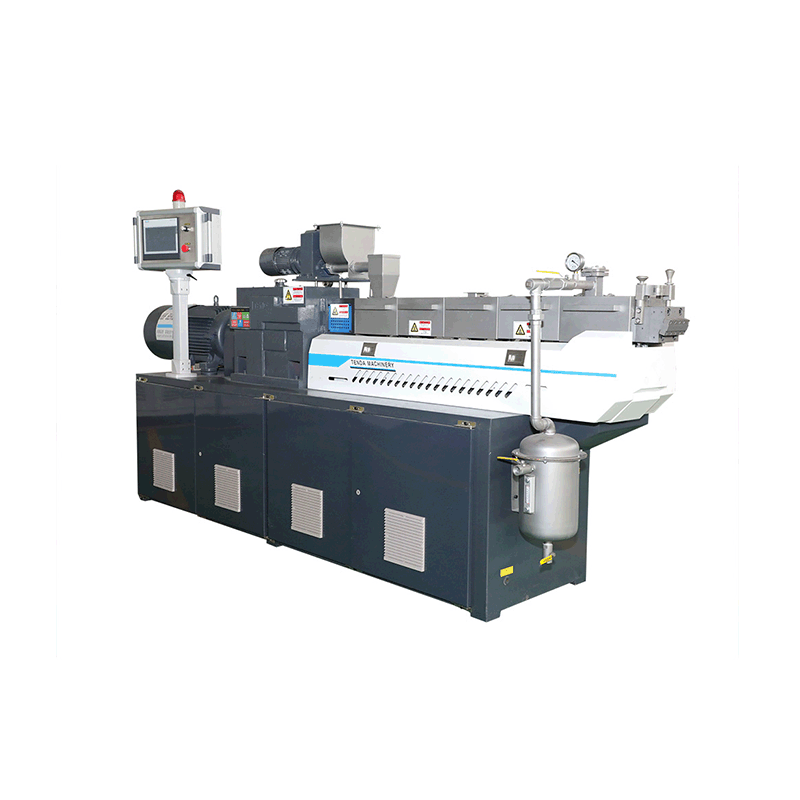

Nanjing Tengda Machinery Co., Ltd. also discusses implications for both research and the practice of operations in building systems to help people succeed in both the short and long run.

Nanjing Tengda Machinery Co., Ltd. has been a leading server of for many years. Visit the website TENGDA Extruder Machine Manufacturers for quality Application.

According to the market analysts, exports from Nanjing Tengda Machinery Co., Ltd. facilities in China will exceed the forecast.